Self-repairing steel slag-slag concrete and preparation method thereof

A self-healing and concrete technology, applied in the field of building materials, can solve the problems of high price of solid sodium silicate, poor economy, and large specific gravity, and achieve the effects of avoiding concrete shrinkage, reducing environmental pollution, and improving activity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

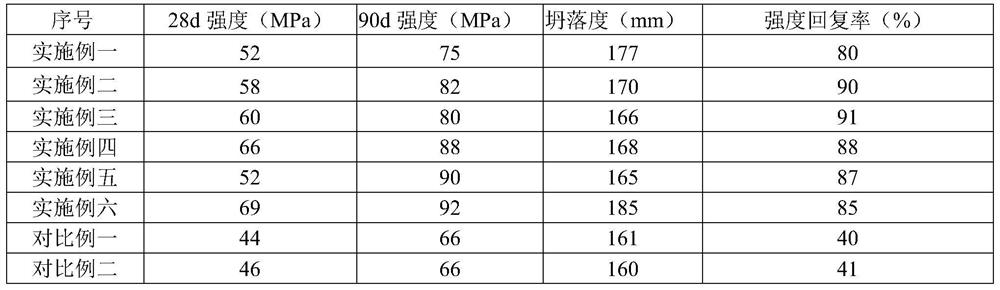

Examples

Embodiment 1

[0034] A preparation method of self-repairing steel slag-slag concrete, the steps are as follows:

[0035] 1) Take 20 parts by mass of steel slag, 10 parts by mass of water, and wet mill 0.2 parts by mass of polycarboxylate superplasticizer for 60 minutes to obtain slurry A. The median particle size of slurry A reaches 3 μm, and 80 parts by mass of slag, 40 parts by mass of water were wet milled for 60 minutes to obtain slurry B, and the median particle size of slurry B was 3 μm;

[0036] 2) Mix slurry A and slurry B obtained in step 1) to obtain slurry C, and stir for 15 seconds with a mortar mixer;

[0037] 3) Add 2 mass parts of prepared slow-release sodium silicate hydroxyapatite capsules, 2 mass parts of sodium phosphate hydroxyapatite capsules, 3 mass parts to the pre-stirred mixed slurry in step 2). Carbide slag dry powder, 5 parts by mass of Na 2 CO 3 , and then use a mortar mixer to stir slowly for 2 minutes and stir quickly for 2 minutes to obtain evenly stirred s...

Embodiment 2

[0039] A preparation method of self-repairing steel slag-slag concrete, the steps are as follows:

[0040]1) Take 20 parts by mass of steel slag, 10 parts by mass of water, and wet mill 0.2 parts by mass of water reducer for 60 minutes to obtain slurry A. The median particle size of slurry A reaches 2 μm, 80 parts by mass of slag, and 40 parts by mass Wet grinding with water for 60 minutes to obtain slurry B, the median particle size of slurry B is 4 μm;

[0041] 2) Mix slurry A and slurry B obtained in step 1) to obtain slurry C, and stir for 15 seconds with a mortar mixer;

[0042] 3) Add 3 parts by mass of prepared slow-release sodium silicate hydroxyapatite capsules, 3 parts by mass of sodium phosphate hydroxyapatite capsules, 3 parts by mass Parts of calcium carbide slag dry powder, 7 parts by mass of Na 2 CO 3 , and then use a mortar mixer to stir slowly for 2 minutes and stir quickly for 2 minutes to obtain evenly stirred self-repairing steel slag-slag concrete.

Embodiment 3

[0044] A preparation method of self-repairing steel slag-slag concrete, the steps are as follows:

[0045] 1) Take 30 parts by mass of steel slag, 15 parts by mass of water, and wet mill 0.2 parts by mass of water reducer for 60 minutes to obtain slurry A. The median particle size of slurry A reaches 2 μm, 70 parts by mass of slag, and 35 parts by mass Wet grinding with water for 60 minutes to obtain slurry B, the median particle size of slurry B is 3 μm;

[0046] 2) Mix slurry A and slurry B obtained in step 1) to obtain slurry C, and stir for 15 seconds with a mortar mixer;

[0047] 3) Add 2 mass parts of prepared slow-release sodium silicate hydroxyapatite capsules, 2 mass parts of sodium phosphate hydroxyapatite capsules, 3 mass parts to the pre-stirred mixed slurry in step 2). Parts of calcium carbide slag dry powder, 5 parts by mass of Na 2 CO 3 , and then use a mortar mixer to stir slowly for 2 minutes and stir quickly for 2 minutes to obtain evenly stirred self-repa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com