Polyimide film and preparation method thereof

A polyimide film and polyamic acid technology, which is applied in the field of organic materials, can solve the problems of reducing the thermal expansion coefficient of the film and failing to meet the requirements of near-zero thermal expansion, and achieve the effects of reducing the thermal expansion coefficient, convenient operation, and easy industrial production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

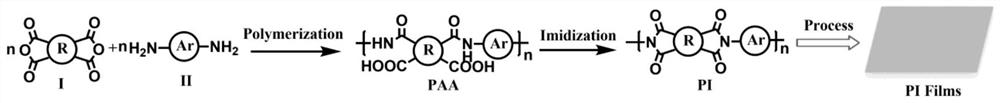

[0047] The invention provides a kind of preparation method of polyimide film, comprises the following steps:

[0048] a) polymerizing aromatic dianhydride monomers and diamine monomers in a solvent to form a polyamic acid precursor solution;

[0049] b) performing casting, curing and heat imidization on the polyamic acid precursor solution to form a polyimide film;

[0050] The diamine monomer is a diamine shown in formula II-a, or a mixture of a diamine shown in formula II-a and other diamine monomers;

[0051] The diamine represented by the formula II-a is selected from one or more of the compounds represented by the formula II-a1 ~ formula II-a3:

[0052]

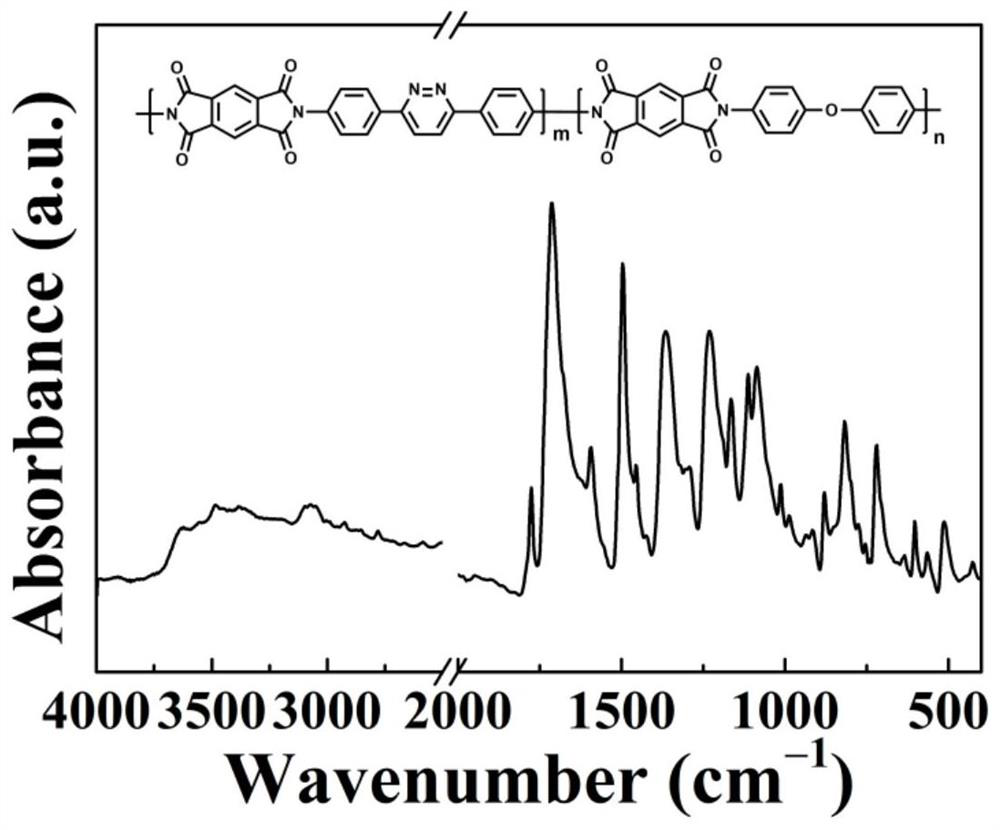

[0053] In the present invention, the polyimide is prepared by reacting the pyridazine-containing diamine monomer represented by the specific formula II-a with the aromatic dianhydride monomer, which can effectively reduce the thermal expansion coefficient of the polyimide film and achieve near-zero thermal expansion ...

preparation example 1

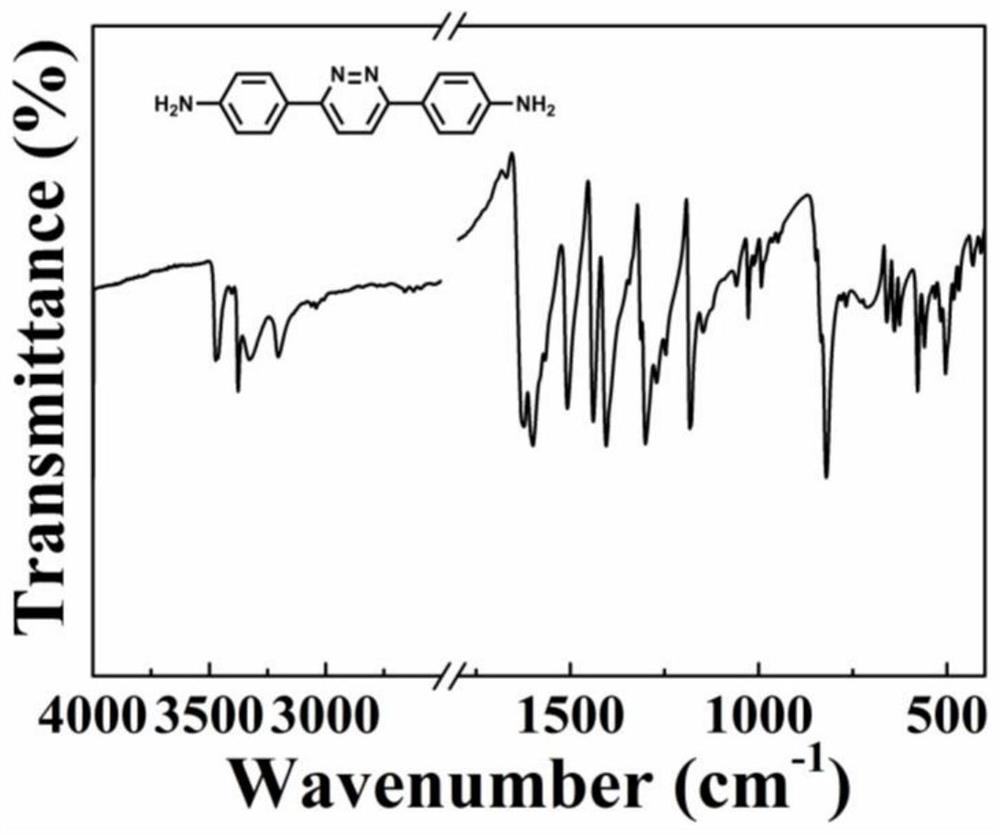

[0110] The preparation of 3,6-bis(4-aminophenyl) pyridazine shown in formula II-a3 of raw material preparation example 1

[0111] Under the protection of nitrogen, 4-aminophenylboronic acid pinacol ester (0.046mol, 10.08g), 3,6-dibromopyridazine (0.021mol, 5.00g), tetrakis (triphenylphosphine) palladium (0.001mol , 1.15g), anhydrous potassium carbonate (0.15mol, 20.73g), 20mL toluene and 20mL deionized water were successively added to a 50mL three-necked flask, and then the reaction was stirred and refluxed at 130°C, monitored by TLC until 3,6-dibromo Pyridazine completely disappeared, the reaction was stopped, cooled to room temperature, a large amount of solids were precipitated and filtered, and then washed with deionized water, toluene and methanol for several times, and dried in vacuum to obtain the crude product; after purification, the yellow crystal 4.79 g, namely 3,6-bis(4-aminophenyl)pyridazine, the yield is 87%.

[0112] 1 H NMR (400MHz, DMSO-d 6 ) δ 7.94 (s, 2H)...

preparation example 2

[0115] The preparation of 3,6-bis(2-aminophenyl) pyridazine shown in the example 2 of raw material preparation Ⅱ-a1

[0116] According to the preparation process of raw material preparation example 1, the difference is that the 4-aminophenylboronic acid pinacol ester in step (1) is replaced by 2-aminophenylboronic acid pinacol ester.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thermal expansion coefficient | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Tensile modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com