Method for preparing wound dressing by wet spinning of montmorillonite intercalated polyacrylonitrile

A technique for polyacrylonitrile and wound dressings, which is applied in the preparation of wound dressings by wet spinning of montmorillonite-intercalated polyacrylonitrile, and in the field of organically modified montmorillonite-intercalated polyacrylonitrile fibers to absorb photosensitive dyes, and can solve the problem of inability to strengthen Bone hardness, slow healing of bone fractures, etc., to ensure antibacterial effect and recyclability, short preparation process, and improve the effect of easy decolorization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

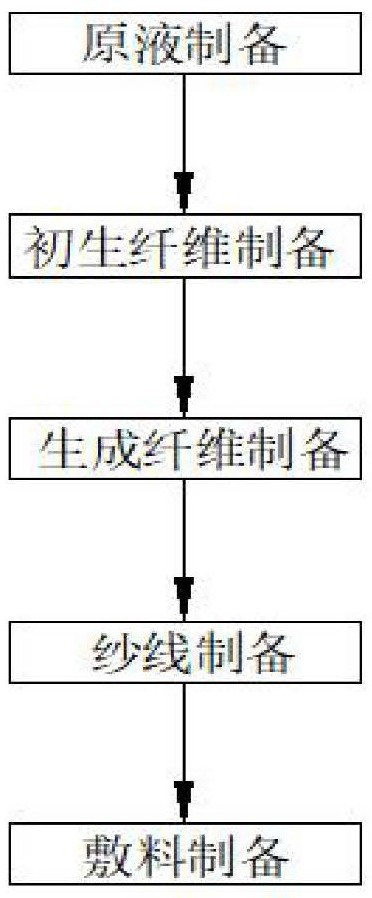

Method used

Image

Examples

example 1

[0025] Add 17 ml of azamide to a 25 ml blue cap bottle. Then 3 g of polyacrylonitrile powder and 5% organically modified montmorillonite were added, ultrasonically pulverized and stirred on a magnetic stirrer for 12 h to prepare spinning stock solution. Then, it was extruded through a spinneret to form nascent fibers, and after passing through a coagulation bath of nitrogen dimethylformamide with a mass fraction of 30% at 30 °C, polyacrylonitrile fibers were produced.

[0026] Then the nascent polyacrylonitrile fibers are washed three times and then stretched to obtain polyacrylonitrile fibers.

[0027] The polyacrylonitrile fiber winding speed was 30 m / min.

[0028] The polyacrylonitrile fiber was soaked in the cationic photosensitizing dye methylene blue solution with a concentration of 80 mg / L for 48 h, and the wound dressing yarn with antibacterial function was prepared. Finally, wound dressings were prepared by weaving wound dressing yarns on a small prototype machine. ...

example 2

[0030] Add 17 ml of azamide to a 25 ml blue cap bottle. Then 3 g of polyacrylonitrile powder and 5% organically modified montmorillonite were added, ultrasonically pulverized and stirred on a magnetic stirrer for 12 h to prepare spinning stock solution. Then, it is extruded through a spinneret to generate primary fibers, and after passing through a nitrogen-dimethylformamide coagulation bath at 30 °C and a mass fraction of 30%, polyacrylonitrile fibers are generated.

[0031] Then the nascent polyacrylonitrile fibers are washed three times and then stretched to obtain polyacrylonitrile fibers.

[0032] The polyacrylonitrile fiber winding speed is 40 m / min.

[0033] The polyacrylonitrile fiber was soaked in the cationic photosensitizing dye methylene blue solution with a concentration of 80 mg / L for 48 h, and the wound dressing yarn with antibacterial function was prepared. Finally, wound dressings were prepared by weaving wound dressing yarns on a small prototype machine.

example 3

[0035] Add 17 ml of azamide to a 25 ml blue cap bottle. Then 3 g of polyacrylonitrile powder and 5% organically modified montmorillonite were added, ultrasonically pulverized and stirred on a magnetic stirrer for 12 h to prepare spinning stock solution. Then, it is extruded through a spinneret to generate primary fibers, and after passing through a nitrogen-dimethylformamide coagulation bath at 30 °C and a mass fraction of 30%, polyacrylonitrile fibers are generated.

[0036] Then the nascent polyacrylonitrile fibers are washed three times and then stretched to obtain polyacrylonitrile fibers.

[0037] The winding speed of polyacrylonitrile fiber was 50 m / min.

[0038] The polyacrylonitrile fiber was soaked in the cationic photosensitizing dye methylene blue solution with a concentration of 80 mg / L for 48 h, and the wound dressing yarn with antibacterial function was prepared. Finally, wound dressings were prepared by weaving wound dressing yarns on a small prototype machine...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com