Extraction method of selenoprotein in cardamine violifolia, selenoprotein obtained by extraction method and application of selenoprotein

A technology of crushed cinnamon leaves and extraction methods, which can be used in applications, protein food processing, plant protein processing, etc., can solve the problems of multiple impurities, high production costs, and long time consumption, and achieve simple extraction methods, low cost, and high efficiency. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

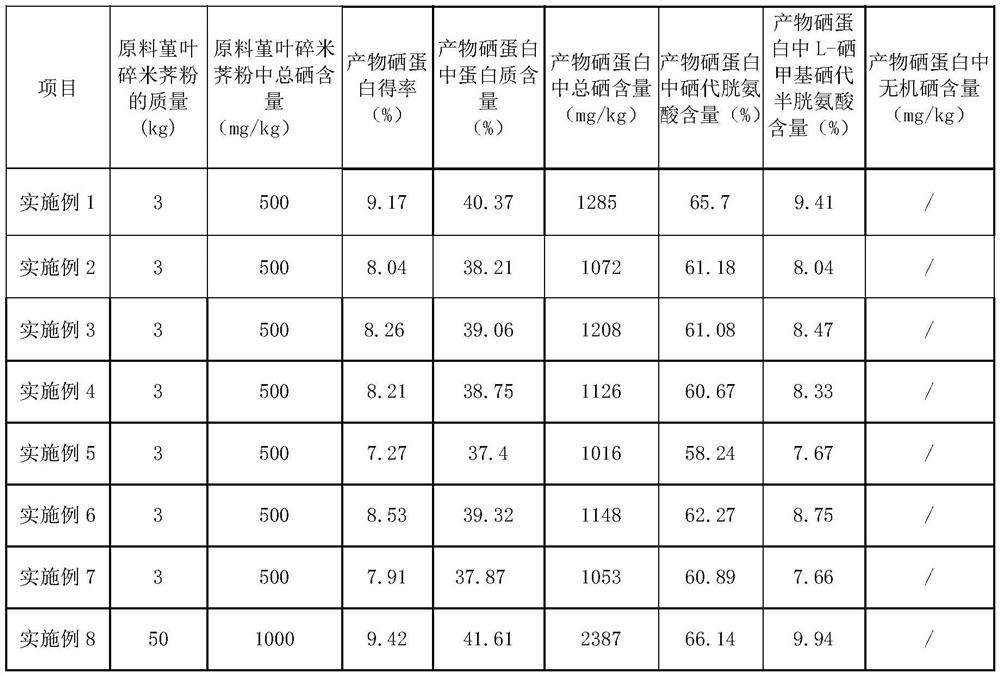

Embodiment 1

[0085] (1) Get 3kg Viola Leaf Broken Rice Chestnut Powder (total selenium content: 500mg / kg), add 75L of purified water, obtain the mixed solution and adjust the pH to 5.0 with food-grade acetic acid, add cellulase, hemicellulase and wood Glycanase, stirred for 2 hours, and kept the temperature in the enzymolysis process at 50°C in a constant temperature water bath, wherein the dosages of cellulase, hemicellulase and xylanase were 90g, 30g and 3g respectively; The mixture after the solution is filtered with a filter plate, and the filtrate obtained continues to be centrifuged using a disc centrifuge to collect the centrifugate; in this centrifugal process, the feed rate is 0.8t / h, and the disc centrifuge rotating speed is 6800r / min. The slag discharge time is 3s, the slag discharge cycle is 5min, and the flushing time is 3s.

[0086] (2) Pass the centrifugate obtained in step (1) through a microfiltration membrane, the microfiltration membrane is a hollow fiber membrane with a...

Embodiment 2

[0089] (1) Get 3kg Viola Leaf Broken Rice Chestnut Powder (total selenium content: 500mg / kg), add 60L of purified water, obtain the mixed solution and adjust the pH to 4.0 with food-grade acetic acid, add cellulase, hemicellulase and wood Glycanase, stirred for 1 hour, and kept the temperature at 45°C in a constant temperature water bath, wherein the dosages of cellulase and xylanase were 75g, 45g and 4.5g respectively; then the mixture after enzymolysis Use a filter plate to filter, and the obtained filtrate continues to be centrifuged with a disc centrifuge to collect the centrifugate; during the centrifugation process, the feed rate is 1t / h, the disc centrifuge speed is 7000r / min, and the slag discharge time is 2s. The slagging period is 4min, and the flushing time is 2s.

[0090] (2) Pass the centrifugate obtained in step (1) through a microfiltration membrane, the microfiltration membrane is a hollow fiber membrane with a molecular weight of 400,000Da, the membrane apertu...

Embodiment 3

[0093] (1) Get 3kg Viola leaf broken rice chestnut powder (total selenium content: 500mg / kg), add 90L of pure water, obtain the mixed solution and adjust pH with food-grade acetic acid to be 6.0, add cellulase, hemicellulase and wood Glycanase, stirred for 3 hours, and kept the temperature in the enzymolysis process at 40°C in a constant temperature water bath, wherein the dosages of cellulase and xylanase were 60g, 60g and 6g respectively; then the mixture after enzymolysis was used The filter plate is filtered, and the obtained filtrate continues to be centrifuged with a disc centrifuge to collect the centrifugate; during the centrifugation process, the feed rate is 0.8t / h, the disc centrifuge speed is 6700r / min, and the slag discharge time is 2s. The slagging period is 3min, and the flushing time is 2s.

[0094](2) Pass the centrifugate obtained in step (1) through a microfiltration membrane, the microfiltration membrane is a hollow fiber membrane with a molecular weight of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com