Preparation method and application of fermentation premix capable of enhancing vitamin stability

A premix and vitamin technology, applied in the direction of bacteria used in food preparation, application, animal feed, etc., can solve problems such as vitamin loss, achieve the effect of reducing loss and enhancing stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

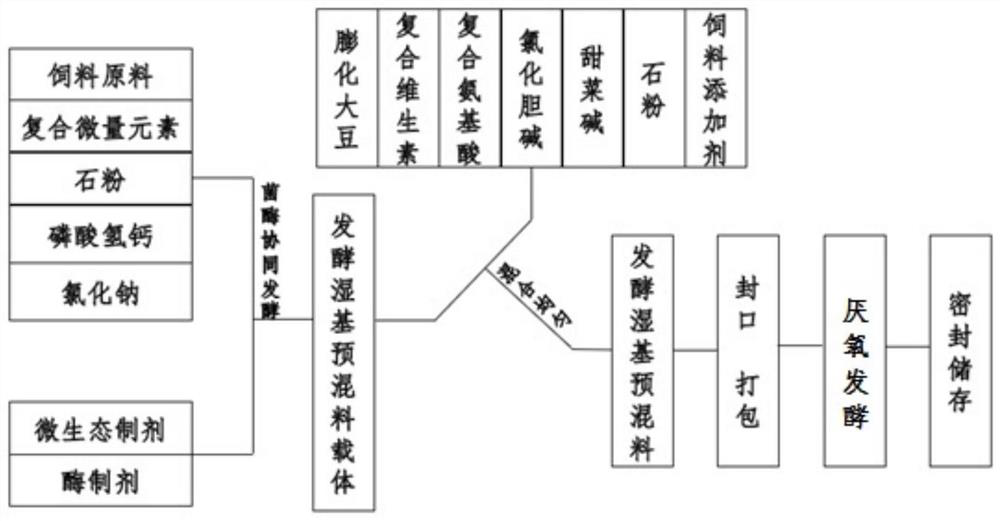

Method used

Image

Examples

Embodiment 1

[0038] Embodiment 1 prepares fermented wet base premix A

[0039] Step 1: 8% corn, 44% soybean meal, 8% pepper meal, 2% compound trace elements, 9.5% calcium hydrogen phosphate, 4% stone powder, 3.95% sodium chloride, 0.25% microbial agent, 0.3% enzyme preparation After mixing evenly with 20% water by weight, ferment at 25°C to 36°C for 72 hours to obtain a fermented wet base premix carrier;

[0040] The components and weight ratios of the microbial agent are respectively: 1*10 10 CFU / g Lactobacillus plantarum 50-80%, 1*10 10 CFU / g Lactobacillus acidophilus 10~30%, 1*10 11 CFU / g Saccharomyces cerevisiae powder 10-20%;

[0041] The components and weight ratios of the enzyme preparation are respectively: 50000U / g neutral protease 20-60%, 200000U / g acid protease 20-40%, 400000U / g xylanase 10-20%, 30000U / g pectinase 10-20%.

[0042] Step 2: The fermented wet-base premix carrier prepared in Step 1 is mixed with multivitamins, compound amino acids, puffed soybeans, stone powde...

Embodiment 2

[0045] Example 2 Preparation of Fermented Wet Base Premix B

[0046] Step 1: 6% corn, 35% soybean meal, 10% pepper meal, 10% bran, 2% compound trace elements, 8% calcium hydrogen phosphate, 3% stone powder, 4% sodium chloride, 0.25% microbial agent, After mixing 0.35% enzyme preparation and 21.4% water uniformly by weight, ferment at 25°C to 36°C for 96 hours to obtain a fermented wet-based premix carrier, the composite trace elements, microbial agents, and enzyme preparations are the same as Example 1.

[0047] Step 2: The fermented wet-base premix carrier prepared in Step 1 is mixed with multivitamins, compound amino acids, puffed soybeans, stone powder, functional additives, choline chloride, and betaine in weight ratios of 65.5%, 1.5%, and 3.0%, 17.2%, 5.0%, 0.3%, 2.5%, and 5.0% were mixed evenly to make a fermented wet base premix base, and the functional additives were the same as in Example 1.

[0048] Step 3: Same as Example 1, obtain the finished fermented wet-based...

Embodiment 3

[0049] Example 3 Preparation of Fermented Wet Base Premix C

[0050] Step 1: 10% corn, 33% soybean meal, 5% pepper meal, 8% bran, 2.3% compound trace elements, 8.5% calcium hydrogen phosphate, 3.6% stone powder, 3.5% sodium chloride, 0.25% microbial agent, 0.15% enzyme preparation and 25.7% water are uniformly mixed by weight, and then fermented at 25°C to 36°C for 48 hours to obtain the prepared fermented wet base premix carrier, the composite trace elements, microbial agents, Enzyme preparation is with embodiment 1.

[0051] Step 2: The fermented wet-based premix carrier prepared in step 1 is mixed with multivitamins, compound amino acids, puffed soybeans, stone powder, functional additives, choline chloride, and betaine in weight ratios of 61.2%, 1.8%, and 61.2%, respectively. 4.5%, 20%, 5.0%, 0.3%, 2.2%, and 5.0% are evenly mixed to make a fermented wet base premix base. Described functional additive is with embodiment 1.

[0052] Step 3: Same as Example 1, obtain the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com