Preparation method and product of a corrosion-resistant coating on the surface of a rare earth permanent magnet material

A rare-earth permanent magnet and corrosion-resistant technology, which is applied in the manufacture of permanent magnets, inductors/transformers/magnets, and coatings. It can solve the problems of chemical corrosion of the substrate, weakened protection of the substrate, and insufficient density of the nickel coating to reduce corrosion. , It is beneficial to the maintenance of the plating solution and the effect of protecting it from corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] A method for preparing a corrosion-resistant coating on the surface of a rare earth permanent magnet material is carried out according to the following steps:

[0027] (1) The equipped cyanide-free alkaline copper plating solution, the other components of the plating solution are: 102g L -1 Sodium glutamate, 32g·L - 1 CuSO 4 ·5H 2 O, the rest is water, use KOH, H 2 SO 4 Adjust the pH of the solution to 8.

[0028] (2) The acid sodium glutamate-copper ion solution equipped, its plating solution is composed of sodium glutamate 102g L -1 , 32g·L -1 CuSO 4 The rest is water, with KOH, H 2 SO 4 Adjust the pH of the solution to 3.

[0029] (3) Sonicate the prepared acidic sodium glutamate-copper ion solution for 10 minutes, then put it into a magnetic stirrer and stir for about 4 hours at a speed of 800 rad / min.

[0030] (4) Use a sample of sintered NdFeB (size 10mm×10mm×h1mm) with a brand name of 35SH, and place the chamfered sample in a 12g·L -1 NaOH, 12g·L -1...

Embodiment 2

[0038] A method for improving the corrosion resistance of sintered NdFeB magnets is carried out according to the following steps:

[0039] (1) The cyanide-free alkaline copper plating solution equipped consists of: 102g L -1 Sodium glutamate, 32g·L -1 CuSO 4 ·5H 2 O, the rest is water, use KOH or H 2 SO 4 Adjust the pH of the solution to 8.

[0040] (2) The sodium glutamate-copper ion-nano-alumina solution equipped, its plating solution is composed of sodium glutamate 102g L -1 , 32g·L -1 CuSO 4 , nano-alumina, the rest is water, with KOH or H 2 SO 4 The pH of the solution was adjusted to 3, and three groups of experiments were set up, and the alumina contents were respectively 5g / L, 10g / L, and 15g / L.

[0041] (3) After adjusting the pH of the prepared acidic sodium glutamate-copper ion-nano-alumina solution, it was ultrasonicated for 10 minutes, then placed in a magnetic stirrer and stirred for about 2 hours at a speed of 1000 rad / min.

[0042] (4) Use a sample of ...

Embodiment 3

[0046] The surface of the sintered NdFeB magnet is pre-plated with copper in an alkaline cyanide-free copper plating solution, and then copper-plated in a glutamic acid copper plating solution. Except that nano-alumina is not added to the glutamic acid copper plating solution, all other steps and processes are consistent with Implementation 2.

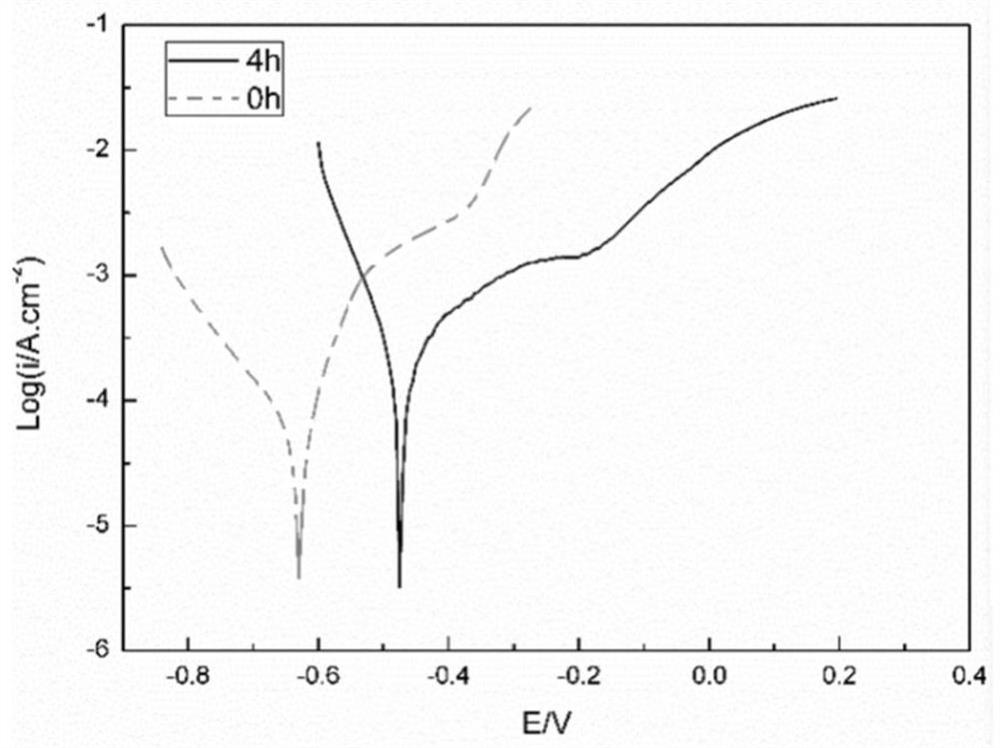

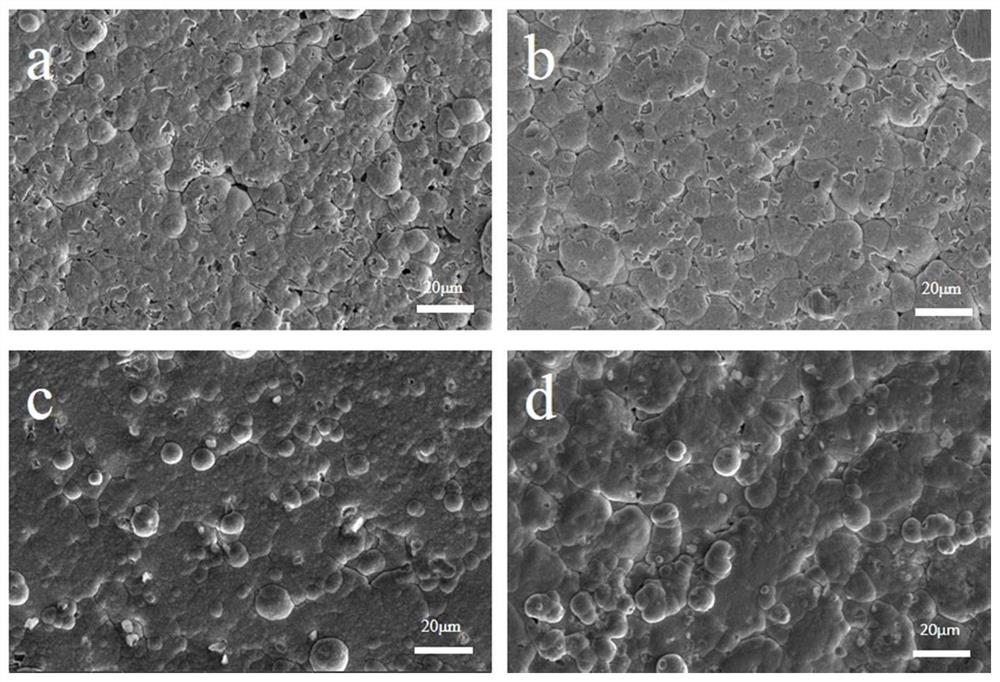

[0047] The sintered NdFeB samples coated with two layers of coatings in Example 2 and Example 3 were washed and dried for surface morphology observation respectively (see image 3 ) and cross-sectional morphology observation (see Figure 4 ), observation of surface film morphology after corrosion (see Figure 5 ), contact angle test (see Figure 6) and electrochemical performance analysis (see Figure 7), and comparative analysis.

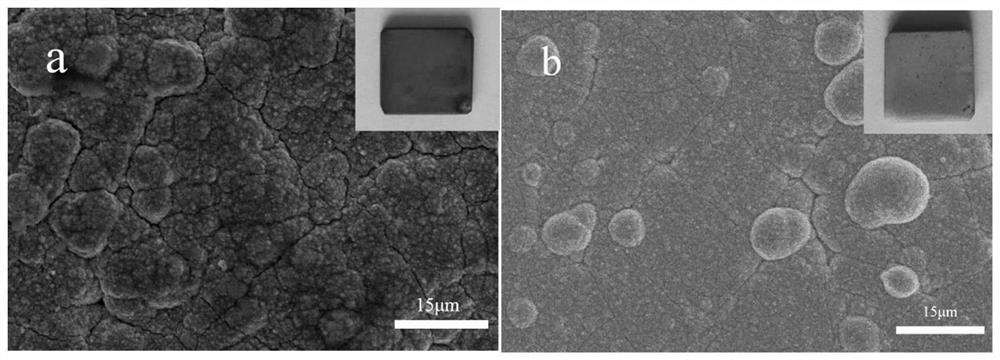

[0048] like image 3 As shown, with the increase of alumina content in the bath, the surface becomes smoother without obvious gaps.

[0049] Figure 4 The cross-sectional topography shows that alkaline c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com