Cadmium Telluride Solar Cells with Tellurium Molybdenum Multilayer Composite Thin Films

A multi-layer composite and solar cell technology, which is applied in the direction of circuits, photovoltaic power generation, electrical components, etc., can solve problems such as negative impact on device stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

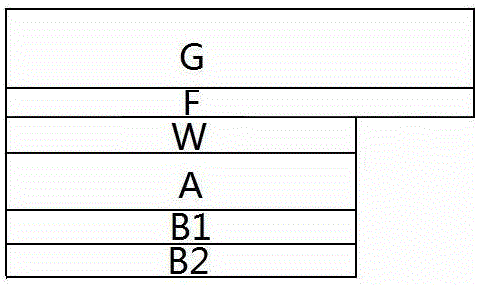

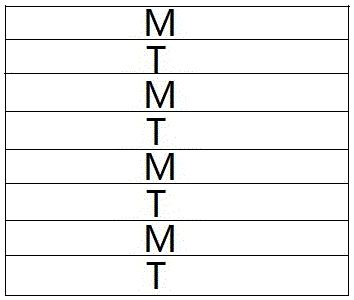

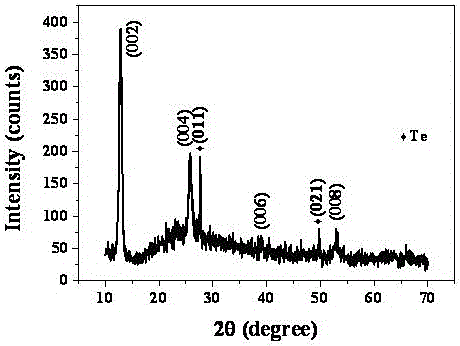

[0017] (1) Preparation of tellurium-molybdenum multilayer composite film

[0018] Put the sample into the vacuum chamber with a vacuum of 10 -4 pa, the sample temperature is room temperature, and the electron beam evaporation method is used to alternately evaporate tellurium and molybdenum, wherein the purity of tellurium is 99.99% and above, and the purity of molybdenum is 99.99% and above. The thickness of deposited tellurium is 1~10nm, the thickness ratio of tellurium and molybdenum is 3.4, and the total thickness of tellurium-molybdenum multilayer composite film is 250 nm;

[0019] (2) Post-processing tellurium molybdenum multilayer composite film

[0020] Take out the sample deposited with tellurium-molybdenum multilayer composite film, put it into a vacuum annealing furnace protected by nitrogen gas, and carry out post-treatment at a temperature of 300 0 C~400 0 C, the time is 10-60 minutes, and then naturally cooled to room temperature, that is, a sample with a thin ...

Embodiment 2

[0022] (1) Install the target and sample

[0023] Fix the tellurium target (purity 99.99% and above) and the molybdenum target (purity 99.99% and above) respectively on the two target positions corresponding to the sputtering device, fix the sample on the substrate position, and adjust the distance between the target and the substrate. The distance is 6~9 cm;

[0024] (2) Preparation of tellurium molybdenum multilayer composite film

[0025] Tellurium and molybdenum were sputtered alternately and sequentially at room temperature to obtain tellurium-molybdenum multilayer composite films, in which the background vacuum was ~10 -4 Pa, the working gas is argon, the working pressure is 0.1~3.5 Pa, the sputtering power of tellurium target is 30~100 W, the sputtering power of molybdenum target is 30~300 W, the thickness of tellurium is 1~10 nm, and the thickness ratio of tellurium and molybdenum is 3 , the total sputtering thickness is 100 nm;

[0026] (3) Post-treatment tellurium...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com