Preparation method of polymer precursor ceramic aerogel

A precursor ceramic and aerogel technology, applied in the field of ceramic aerogel, can solve the problems of high oxygen content, low ceramic yield, insufficient purity of ceramic aerogel, etc., to achieve simplified process, high ceramic yield, shortening time The effect of preparation time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

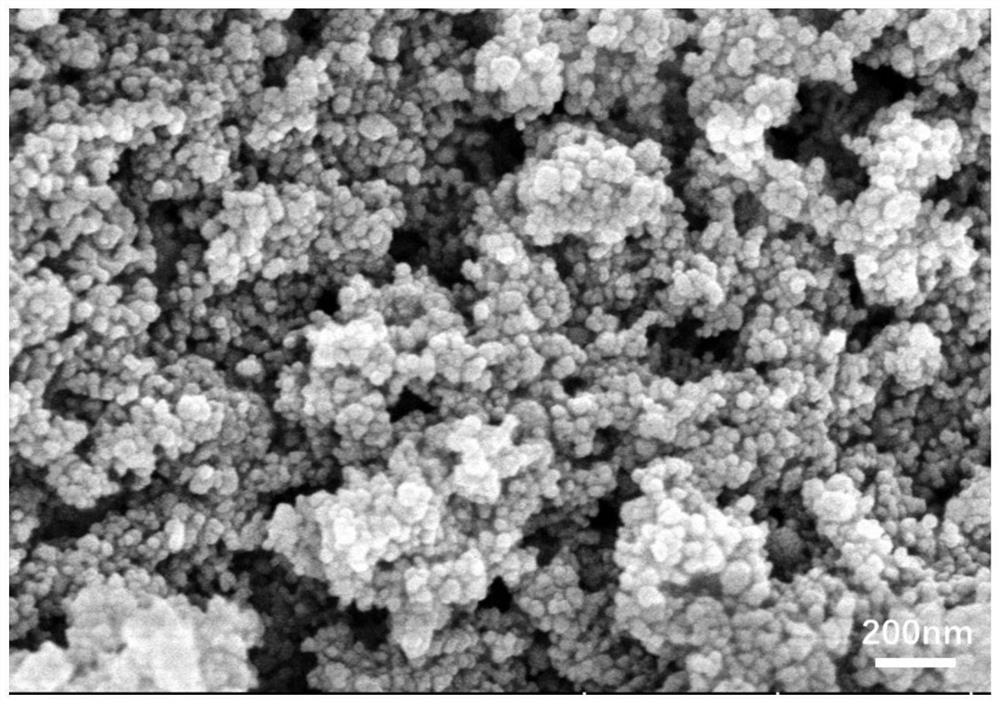

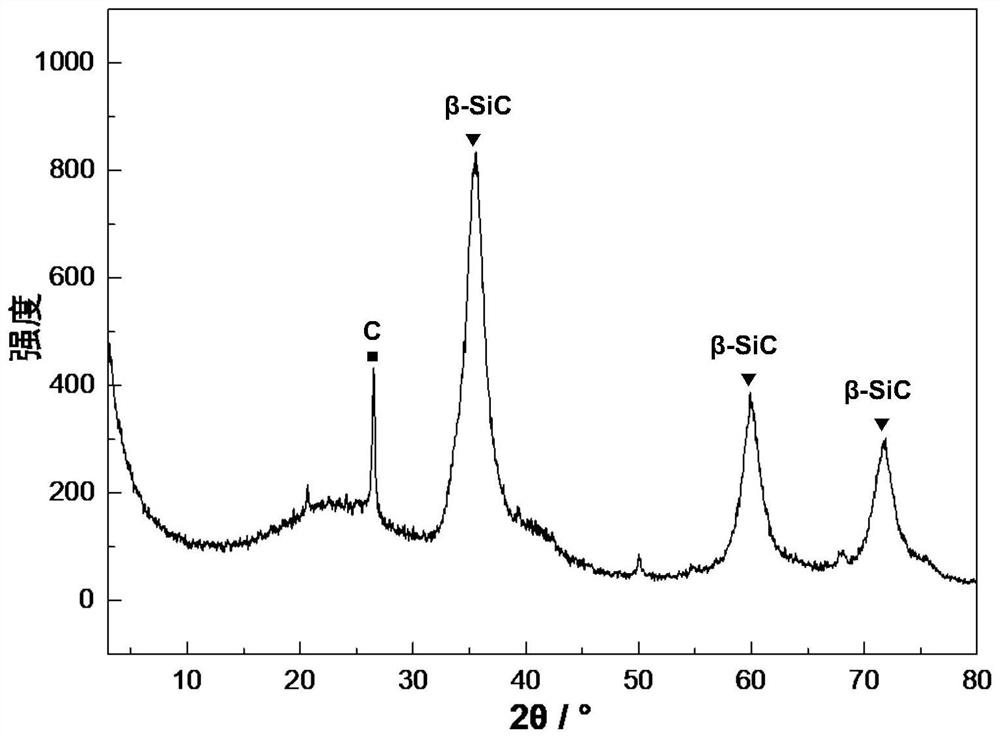

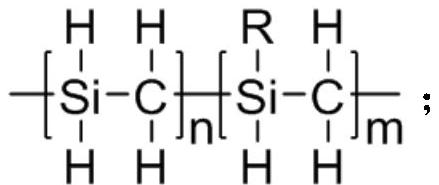

[0037] Under the protection of nitrogen, 5 g of precursor polymers were uniformly dispersed in 95 g of n-hexane to obtain a precursor solution with a concentration of 5 wt %; 3 μL of 0.1 wt % Karstedt catalyst solution was added to the precursor solution, and under nitrogen protection, After stirring evenly, transfer it to a pressure reactor filled with nitrogen, and react at 160°C for 4 hours to obtain a light yellow silicon carbide precursor wet gel; after taking it out, soak it in cyclohexane for 2 days, and replace the cyclohexane 3 times; the wet gel was passed through supercritical CO 2 Dry 3 times, each time for 3 days, to obtain the silicon carbide precursor airgel; place the airgel in a high-temperature tube furnace, and raise the temperature to 1500°C at a rate of 3°C / min under high-purity argon, And keep it warm for 2 hours to obtain silicon carbide ceramic airgel. The obtained silicon carbide ceramic airgel has a density of 0.2g / cm 3 , with a specific surface are...

Embodiment 2

[0039] Under the protection of nitrogen, 20 g of the precursor polymer was uniformly dispersed in 80 g of tetrahydrofuran to obtain a precursor solution with a concentration of 20 wt %; 2 μL of 0.1 wt % Karstedt catalyst solution was added to the precursor solution, and stirred under the protection of nitrogen After uniformity, transfer to a pressure reactor filled with nitrogen, and react at 100 °C for 5 hours to obtain a light yellow silicon carbide precursor wet gel; after taking it out, soak it in tetrahydrofuran for 2 days, and replace tetrahydrofuran 3 times during the period; The silicon carbide precursor airgel was obtained by freeze-drying the gel; the airgel was placed in a high-temperature tube furnace, and under high-purity argon, the temperature was raised to 800°C at a rate of 5°C / min, and kept for 4h , to obtain silicon carbide ceramic airgel. The obtained silicon carbide ceramic airgel has a density of 0.361g / cm 3 , the specific surface area is 820m 2 / g, the...

Embodiment 3

[0041] Under the protection of nitrogen, 10 g of the precursor polymer was uniformly dispersed in 90 g of chloroform to obtain a precursor solution with a concentration of 10 wt %; 1 μL of 0.01 wt % Karstedt catalyst solution was added to the precursor solution, and the , after stirring evenly, transferred to a pressure reactor filled with nitrogen, and reacted at 200°C for 6 hours to obtain a light yellow silicon carbide precursor wet gel; after taking it out, soak it in chloroform for 2 days, and replace the chloroform during the process 3 times; pass the wet gel through supercritical CO 2 Dry 3 times, each time for 3 days, to obtain the silicon carbide precursor airgel; place the airgel in a high-temperature tube furnace, and raise the temperature to 1500°C at a rate of 6°C / min under high-purity argon, And keep it warm for 1 hour to obtain silicon carbide ceramic airgel. The obtained silicon carbide ceramic airgel has a density of 0.187g / cm 3 , the specific surface area i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com