Fluorescent powder applied to electrochemical detection as well as preparation and application methods thereof

An application method and phosphor technology, applied in the direction of chemical instruments and methods, material electrochemical variables, measuring devices, etc., can solve the problems of low power of batteries and capacitors, complex instruments and equipment, low energy density, etc., to increase production, prepare The effect of simple process, high yield and high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

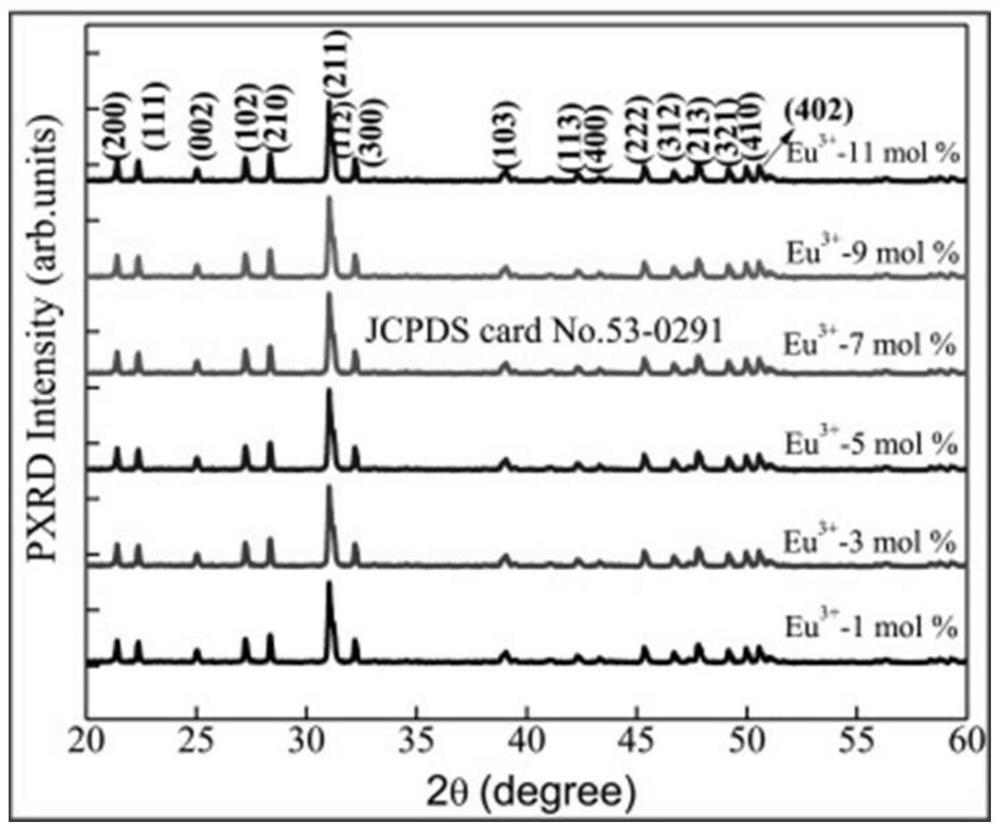

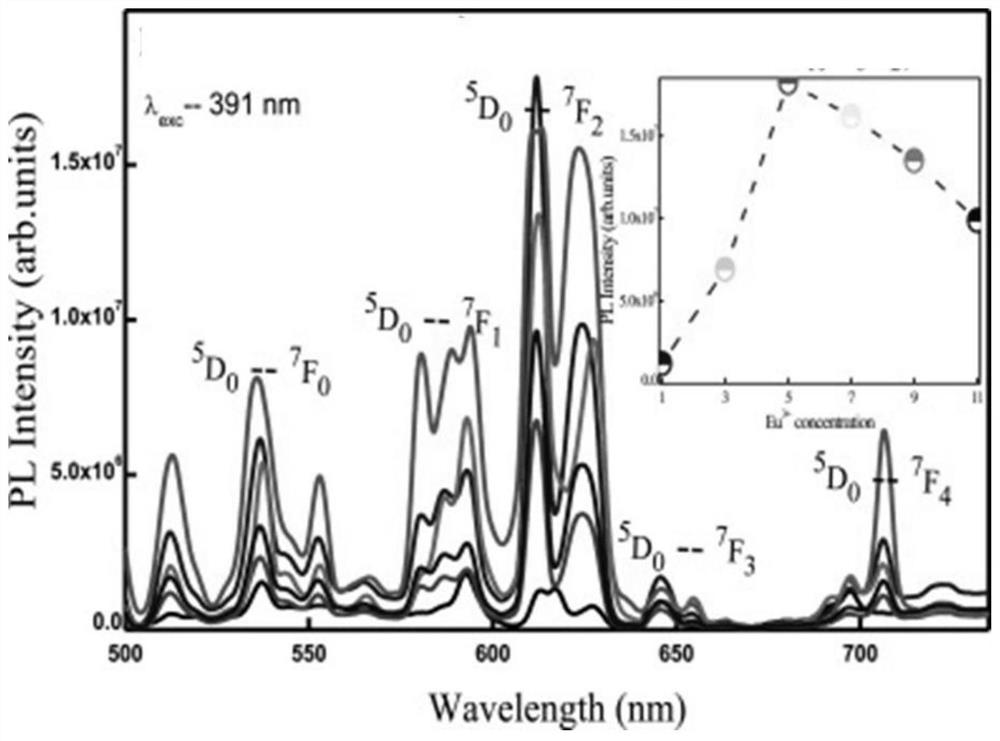

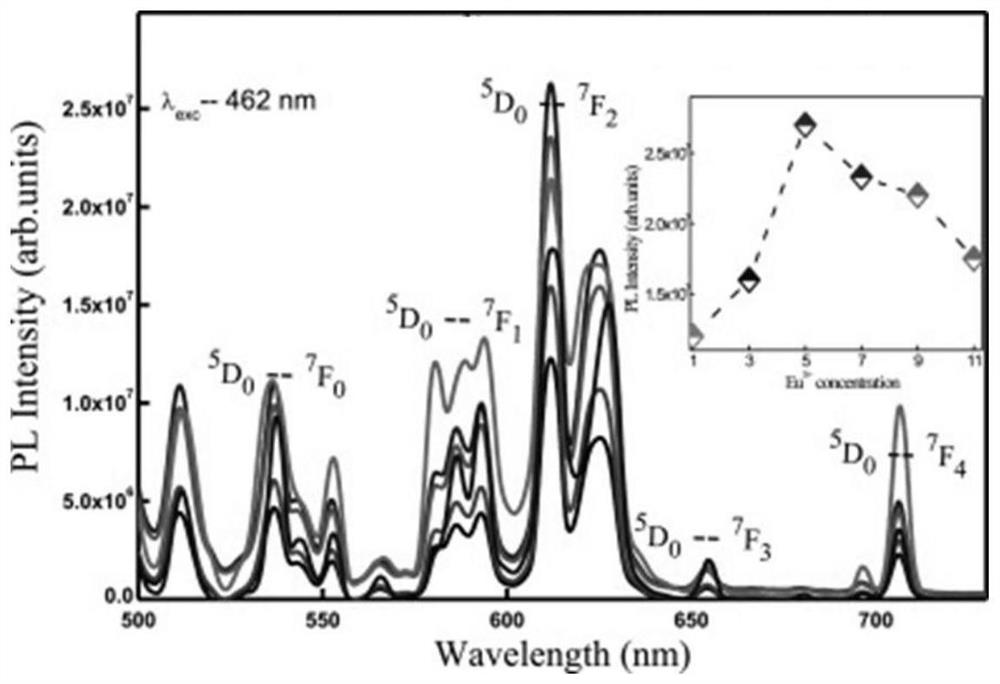

[0018] Example 1: Lu 10 Si 6 o 27 :1%Eu 3+

[0019] Phosphor powder preparation: Weigh Lu(NO 3 ) 3 , Eu(NO 3 ) 3 , SiO 2 For ingredients, mix well. The mixed raw material and urea are mixed according to a mass ratio of 2 and stirred at room temperature at 200 rpm. After stirring, it was heated at 500°C for 0.5h to obtain a powder. Calcining the powder at 1000° C. for 2 hours, and grinding to obtain the phosphor.

[0020] Preparation of carbon paste electrode: Grind phosphor powder, graphite powder and silicone oil in an agate mortar to form a uniform paste, wherein the mass ratio of graphite powder to phosphor powder is 5, and the mass ratio of graphite powder to silicone oil is 2. The paste is put into the electrode hollow tube to obtain the carbon paste electrode.

Embodiment 2

[0021] Example 2: Lu 10 Si 6 o 27 :3%Eu 3+

[0022] Phosphor powder preparation: Weigh Lu(NO 3 ) 3 , Eu(NO 3 ) 3 , SiO 2 For ingredients, mix well. The mixed raw material and urea were mixed according to a mass ratio of 0.5 and stirred at room temperature at 300 rpm. After stirring, it was heated at 400°C for 2h to obtain a powder. The powder was calcined at 900° C. for 5 hours and ground to obtain the phosphor.

[0023] Preparation of carbon paste electrodes: Grind phosphor powder, graphite powder and silicone oil in an agate mortar to form a uniform paste, wherein the mass ratio of graphite powder to phosphor powder is 2, and the mass ratio of graphite powder to silicone oil is 4. The paste is put into the electrode hollow tube to obtain the carbon paste electrode.

Embodiment 3

[0024] Example 3: Lu 10 Si 6 o 27 :5%Eu 3+

[0025] Phosphor powder preparation: Weigh Lu(NO 3 ) 3 , Eu(NO 3 ) 3 , SiO 2 For ingredients, mix well. The mixed raw material and urea are mixed according to a mass ratio of 1 and stirred at room temperature at 280 rpm. After stirring, it was heated at 450° C. for 1 h to obtain a powder. The powder was calcined at 950° C. for 3 hours and ground to obtain the phosphor.

[0026] Preparation of carbon paste electrodes: Grind phosphor powder, graphite powder and silicone oil in an agate mortar to form a uniform paste, wherein the mass ratio of graphite powder to phosphor powder is 4, and the mass ratio of graphite powder to silicone oil is 3. The paste is put into the electrode hollow tube to obtain the carbon paste electrode.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com