A modified polyimide based microwave absorbing material for microwave anechoic chambers, absorbing structure and preparation method thereof

A polyimide-based, microwave anechoic chamber technology, applied in the field of microwave-absorbing materials, to achieve the effect of improving heat insulation, good sound insulation performance, and maintaining a constant temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

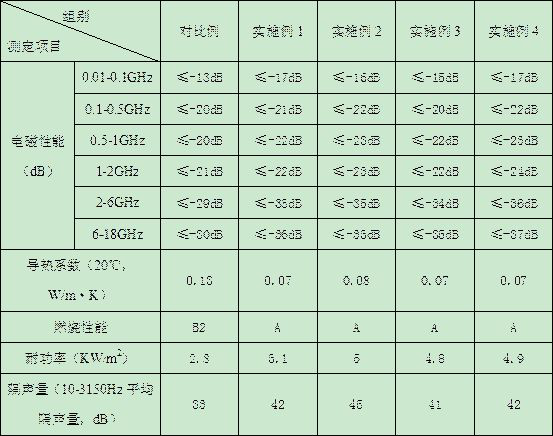

Embodiment 1

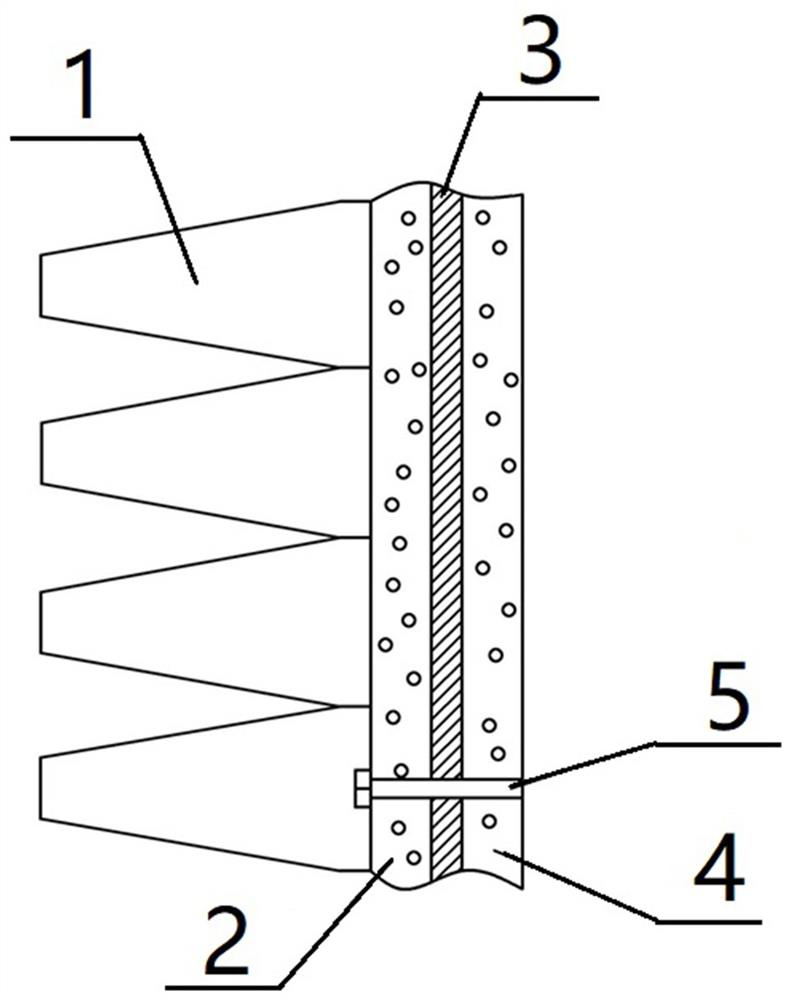

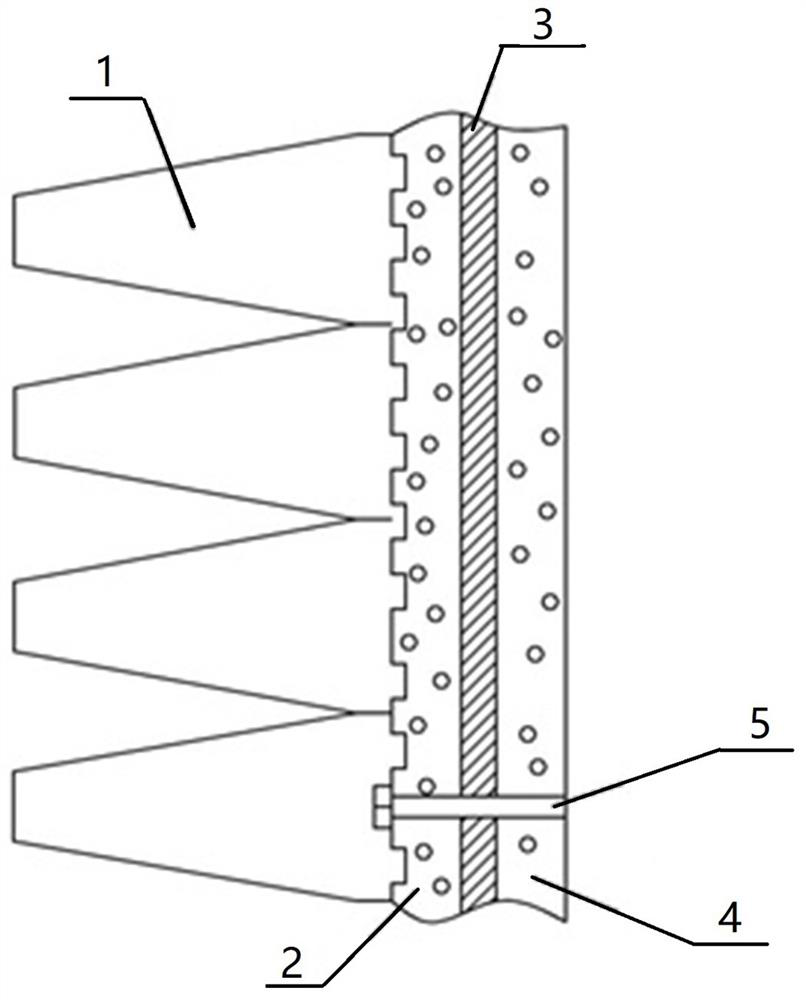

[0047] 1) Preparation of polyimide foam precursor composite absorbing material absorbing pyramid

[0048] In parts by mass, 85% polyimide foaming precursor, 0.2% tetrahydrofuran, 8% modified carbon nanotubes, 2.8% magnetic iron nanomaterials, 4% retinyl Schiff alkali metal Salt complexes, 100% in total, are fully mixed and dried, placed in a pyramidal foaming mold with a first preheating temperature of 80°C for 0.5h, and then the temperature is raised to the second foaming temperature of 140°C, and kept warm 3h; then raise the temperature to the third imidization temperature of 300°C, and keep it warm for 2h; after the warming is over, lower it to room temperature, and then prepare a polyimide foaming precursor composite wave-absorbing material wave-absorbing pyramid.

[0049] 2) Preparation of modified aluminum foam

[0050]In parts by mass, 90% of aluminum powder, 4% of modified carbon nanotubes, 3% of magnetic iron nano-magnetic beads, 1% of silicon carbide, and 2% of tita...

Embodiment 2

[0054] 1) Preparation of polyimide foam precursor composite absorbing material absorbing pyramid

[0055] In parts by mass, 88% polyimide foaming precursor, 0.5% tetrahydrofuran, 2.5% modified carbon nanotubes, 6% magnetic iron nanomaterials, 3% retinyl Schiff alkali metal Salt complexes, 100% in total, are fully mixed and dried, placed in a pyramidal foaming mold with the first preheating temperature of 85°C for 0.4h, then raised to the second foaming temperature of 142°C, and kept warm 2.7h; then raise the temperature to the third imidization temperature of 305°C, and keep it warm for 1.8h; after the heat preservation is over, lower it to room temperature, and then prepare a polyimide foaming precursor composite wave-absorbing material absorbing pyramid .

[0056] 2) Preparation of modified aluminum foam

[0057] In parts by mass, 91% of aluminum powder, 3% of modified carbon nanotubes, 1.5% of magnetic iron nano-magnetic beads, 3% of silicon carbide, and 1.5% of titanium ...

Embodiment 3

[0061] 1) Preparation of polyimide foam precursor composite absorbing material absorbing pyramid

[0062] In parts by mass, 93% polyimide foaming precursor, 0.8% tetrahydrofuran, 5.6% modified carbon nanotubes, 0.5% magnetic iron nanomaterials, 0.1% retinyl Schiff alkali metal Salt complexes, 100% in total, are fully mixed and then dried, placed in a pyramidal foaming mold with a first preheating temperature of 95°C for 0.2h, then raised to the second foaming temperature of 145°C, and kept warm 2.5h; then raise the temperature to the third imidization temperature of 315°C, and keep it warm for 1.5h; after the heat preservation is over, lower it to room temperature, and then a polyimide foaming precursor composite wave-absorbing material wave-absorbing pyramid is prepared. .

[0063] 2) Preparation of modified aluminum foam

[0064] In terms of parts by mass, 93% of aluminum powder, 2.5% of modified carbon nanotubes, 2% of magnetic iron nano-magnetic beads, 1.5% of silicon ca...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com