High-concentration brine evaporative crystallization device and method

A technology for evaporative crystallization and concentrated brine, applied in the field of water treatment, can solve the problems of not involving heavy organic matter, accelerating clogging, affecting crystallization, etc., to reduce the probability, ensure normal progress, and facilitate desorption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0104] Concentrated brine raw material: The raw material is the same as Comparative Example 1.

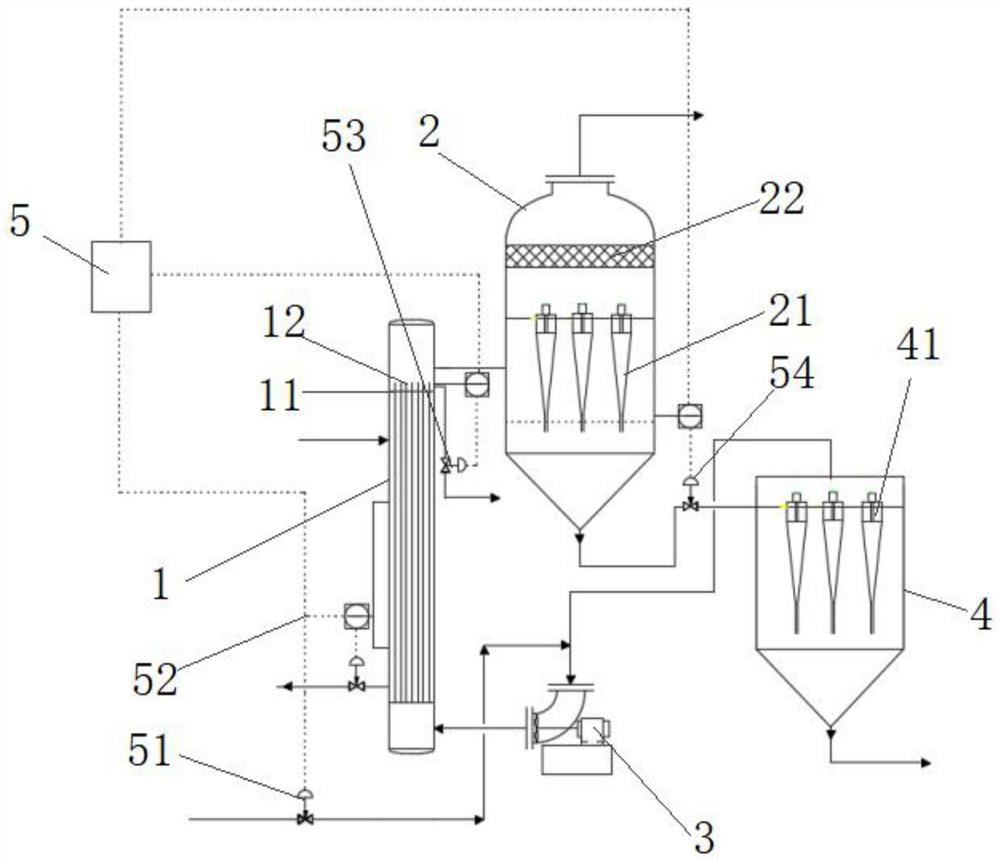

[0105] Evaporation and crystallization process-the high-concentration brine evaporation and crystallization device (+secondary vapor compression) of the present invention: adopts MVR evaporation and crystallization technology. A vapor compressor is provided at the vaporization steam outlet of the high-concentration brine evaporation crystallization device of the present invention to adapt to MVR evaporation crystallization. After the concentrated brine feed water is mixed with the circulating mother liquor, it is sent to the evaporator by the circulating pump to be heated and evaporated. The generated secondary steam enters the steam compressor after passing through the mist eliminator to remove small impurities. The compressed steam enters the shell side of the evaporator for cyclic heating and utilization, and after heat exchange, the steam is converted into condensate for recov...

Embodiment 2

[0110] Concentrated brine raw material: The raw material is the same as Comparative Example 1.

[0111] Evaporation and crystallization process—the high-concentration brine evaporation and crystallization device of the present invention is the same process as that of implementation 1.

[0112] Process operating conditions

[0113] project data cycle ratio 85 Evaporation chamber pressure, MPa(G) -0.07~-0.08 Evaporation chamber temperature, ℃ 64~65 Heat exchanger tube flow rate 3.0

[0114] Operation effect: the evaporator has no fouling phenomenon, the heat transfer efficiency is high, and the device operates continuously; since the organic matter in the concentrated brine is separated out of the system in the evaporator, the phase separator cannot produce foam, and because the steam is pretreated by the cyclone After entering the demister to remove foam, the intolerant inorganic salt can be ignored for the demister, the entrainment of s...

Embodiment 3

[0116] Concentrated brine raw material: The raw material is the same as that of Comparative Example 2.

[0117] Evaporation and crystallization process—the high-concentration brine evaporation and crystallization device of the present invention is the same process as that of implementation 1.

[0118] Process operating conditions

[0119] project data cycle ratio 70 Evaporation chamber pressure, MPa(G) -0.07~-0.08 Evaporation chamber temperature, ℃ ~65 Heat exchanger tube flow rate 3.9

[0120] Operation effect: the evaporator has no fouling phenomenon, the heat transfer efficiency is high, and the device operates continuously; since the organic matter in the concentrated brine is separated out of the system in the evaporator, the phase separator cannot produce foam, and because the steam is pretreated by the cyclone After entering the demister to remove foam, the intolerant inorganic salt can be ignored for the demister, the entrainmen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com