Synthesis method and application of glycidyl acrylate

A technology of glycidyl ester and synthesis method, applied in the direction of organic chemistry, can solve the problems of expensive raw materials, high cost, unfavorable environmental protection, etc., and achieve the effect of improving economic benefits, increasing income, and mild process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

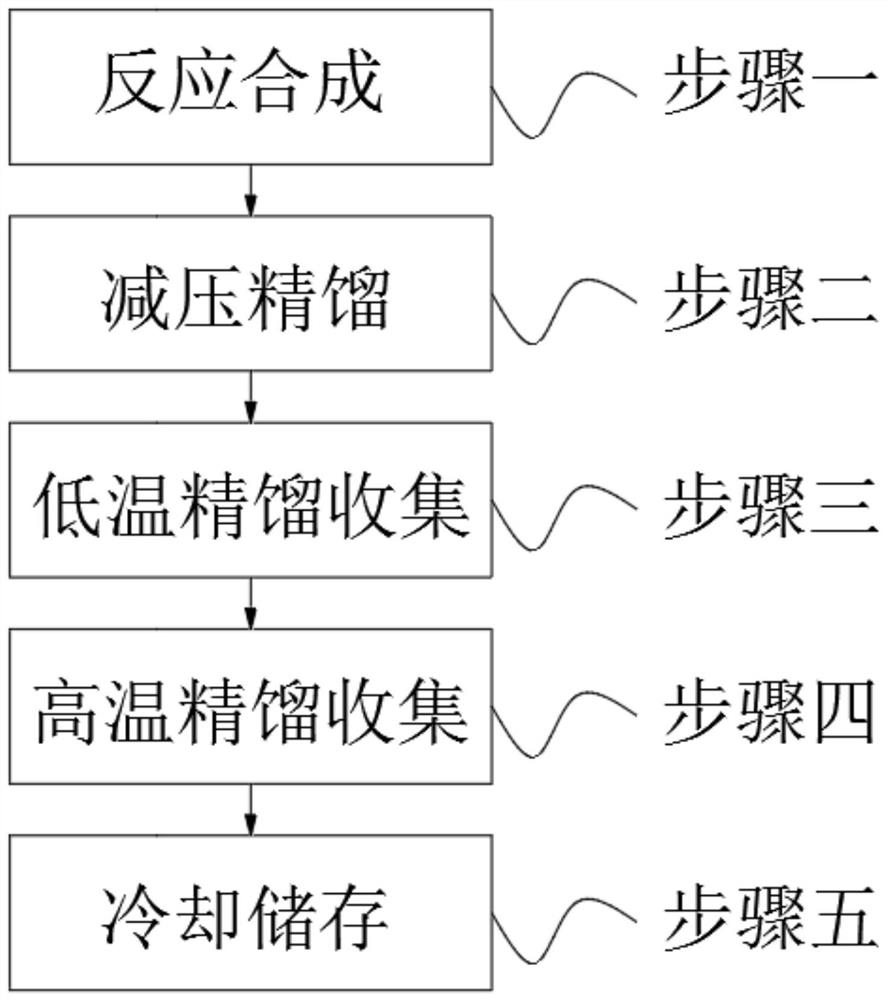

[0023] A synthesis method and application of glycidyl acrylate, comprising the following steps: Step 1, reaction synthesis; Step 2, vacuum rectification; Step 3, low-temperature rectification collection; Step 4, high-temperature rectification collection; Step 5, cooling store;

[0024] Wherein in the above step 1, sodium acrylate, epichlorohydrin and PEG400 were weighed respectively according to the ratio of parts by weight of 94:270:1.5, and then put into a 500-liter stirred tank, stirred evenly, heated and kept warm, and heated up under stirring To 60 ℃, heat preservation reaction time is 5h, after the reaction is completed, the crude glycidyl acrylate is produced, and the solid sodium chloride produced by the reaction can be washed with epichlorohydrin, dried, packaged and sold as a by-product, which significantly increases the income ;

[0025] Wherein in the above step two, the glycidyl acrylate crude product prepared in step one is subjected to vacuum vacuum rectificati...

Embodiment 2

[0030] A synthesis method and application of glycidyl acrylate, comprising the following steps: Step 1, reaction synthesis; Step 2, vacuum rectification; Step 3, low-temperature rectification collection; Step 4, high-temperature rectification collection; Step 5, cooling store;

[0031] Wherein in the above step 1, sodium acrylate, epichlorohydrin and PEG800 were weighed respectively according to the ratio of parts by weight of 94:270:1.5, and then put into a 500-liter stirred tank, stirred evenly, heated and kept warm, and the temperature was raised under stirring To 60 ℃, heat preservation reaction time is 5h, after the reaction is completed, the crude glycidyl acrylate is produced, and the solid sodium chloride produced by the reaction can be washed with epichlorohydrin, dried, packaged and sold as a by-product, which significantly increases the income ;

[0032] Wherein in the above step two, the glycidyl acrylate crude product prepared in step one is subjected to vacuum v...

Embodiment 3

[0037] A synthesis method and application of glycidyl acrylate, comprising the following steps: Step 1, reaction synthesis; Step 2, vacuum rectification; Step 3, low-temperature rectification collection; Step 4, high-temperature rectification collection; Step 5, cooling store;

[0038] Wherein in the above step 1, sodium acrylate, epichlorohydrin and PEG1000 were weighed respectively according to the ratio of parts by weight of 94:270:1.5, and then put into a 500-liter stirred tank, stirred evenly, heated and kept warm, and heated up under stirring To 60 ℃, heat preservation reaction time is 5h, after the reaction is completed, the crude glycidyl acrylate is produced, and the solid sodium chloride produced by the reaction can be washed with epichlorohydrin, dried, packaged and sold as a by-product, which significantly increases the income ;

[0039] Wherein in the above step two, the glycidyl acrylate crude product prepared in step one is subjected to vacuum vacuum rectificat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com