Silole derivative, preparation method and application thereof and photoluminescence lubricating grease

A technology of derivatives and lubricating grease, applied in the field of silole derivatives with luminescent properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

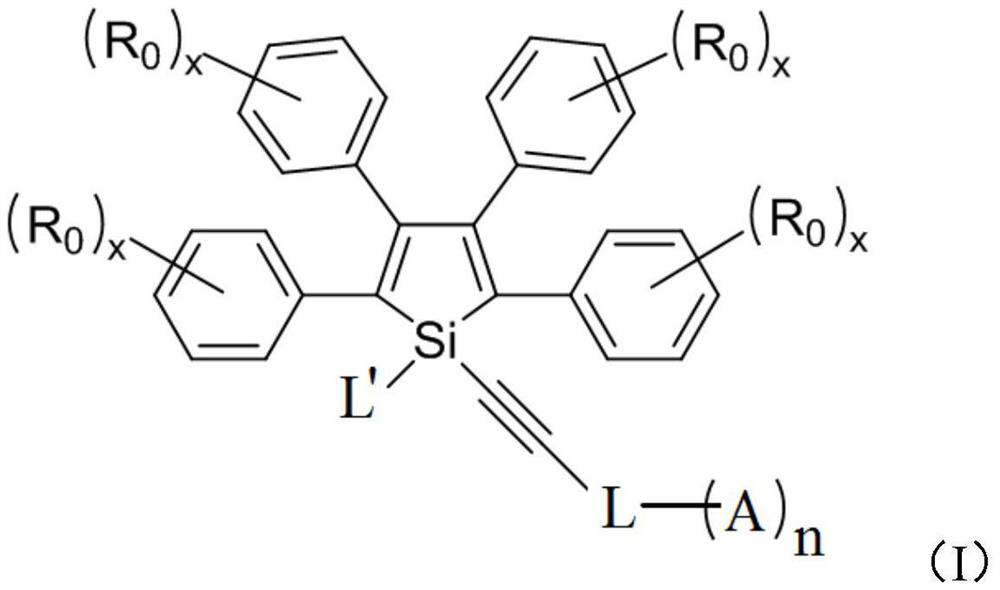

Method used

Image

Examples

Embodiment 1

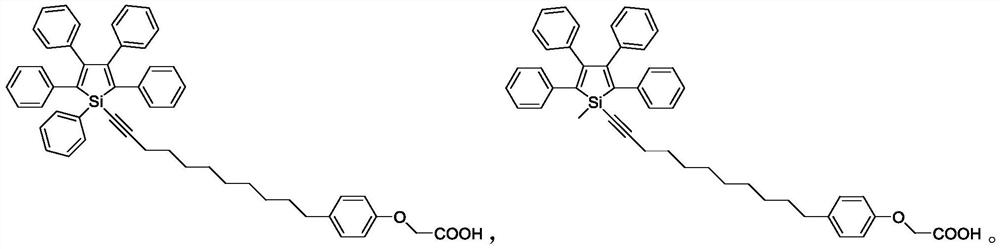

[0058] In a 100mL Schlenk reaction flask, add 1mmol 1-alkynyl-1,2,3,4,5-pentaphenylsilole, 1.2mmol 1-bromononylphenoxyacetic acid, 0.1mmol cuprous iodide, 0.1mmol triphenyl Phosphine, under the protection of nitrogen, add 0.02mmol tetrakistriphenylphosphine palladium, 30mL tetrahydrofuran / triethylamine (2 / 1, v / v), and react at room temperature for 48 hours. After the reaction, filter and spin the filtrate to dryness, use dichloromethane / petroleum ether (1 / 2, v / v) mixed solvent as eluent to separate and purify the product by column chromatography to obtain a yellow solid product, product The rate is 70%. The mass spectrometry result of the product is: MS (MALDI-TOF): m / z calcd: 762.4[M] + , found: 762.4.

[0059] The reaction formula of embodiment 1 is as follows:

[0060]

Embodiment 2

[0062] In a 100mL Schlenk reaction flask, add 1mmol 1-methyl-1-ynyl-2,3,4,5-tetraphenylsilole, 1.2mmol 1-bromononylphenoxyacetic acid, 0.1mmol cuprous iodide, 0.1 mmol triphenylphosphine, under the protection of nitrogen, add 0.02mmol tetrakistriphenylphosphine palladium, 30mL tetrahydrofuran / triethylamine (2 / 1, v / v), react at room temperature for 48 hours. After the reaction, filter and spin the filtrate to dryness, use dichloromethane / petroleum ether (1 / 2, v / v) mixed solvent as eluent to separate and purify the product by column chromatography to obtain a yellow solid product, product The rate is 74%. The mass spectrometry result of the product is: MS (MALDI-TOF): m / zcalcd: 700.3[M] + , found: 700.3.

[0063] The reaction formula of embodiment 2 is as follows:

[0064]

Embodiment 3

[0066] 145 grams of PAO 10 base oil and 44.39 grams of octadecylamine were mixed and heated to 60°C in a reactor, and 0.5 grams of 1-(nonylphenoxyacetic acid)-1,2,3, Dissolve 4,5-pentaphenylsilole in 5 grams of toluene and add it to the reactor, mix 145 grams of PAO 10 base oil and 20.61 grams of MDI and heat it to 60°C, add it to the reactor after the MDI is completely dissolved, and raise the temperature React at 80°C for 30 minutes, continue to heat up to 210°C, then add 145 grams of PAO 10 base oil, cool to about 100°C, grind to fat.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com