High-thermal-conductivity silver paste for bonding high-power component and preparation method of high-thermal-conductivity silver paste

A high-power component, high thermal conductivity technology, used in adhesives, adhesive types, conductive adhesives, etc. Bond strength and thermal stability, and the effect of ensuring bond stability and service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

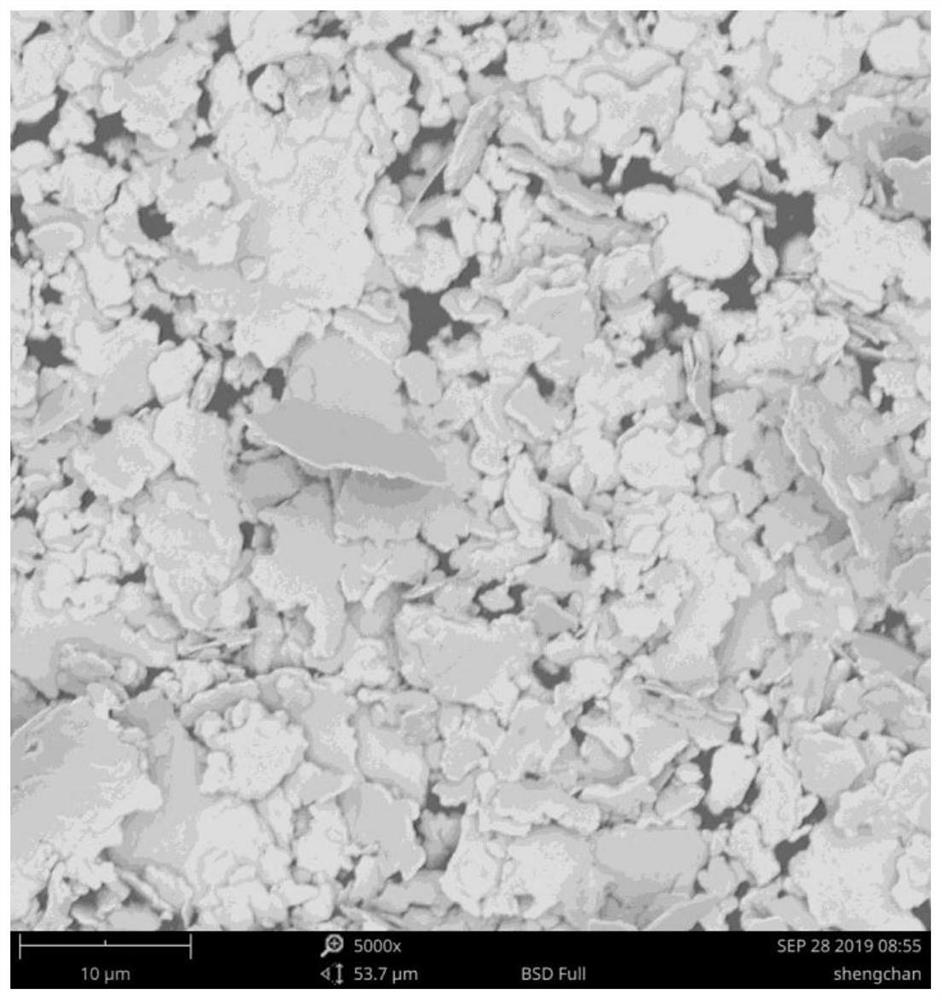

[0066] Embodiment 1: the preparation of flaky silver powder

[0067] 1) Preparation of silver nitrate (AgNO 3 ) solution: place a 2L beaker in a water bath at 40°C, inject 600mL deionized water into the beaker, and then add 200g AgNO 3 , turn on the mechanical stirring, wait for the AgNO 3 After complete dissolution, add dispersant and continue stirring for 10 minutes to obtain AgNO 3 aqueous solution;

[0068] 2) Preparation of Ag 2 CO 3 Suspension: Dissolve Na with 480mL deionized water 2 CO 3 Dissolved, and slowly added to the solution obtained in step 1), after the addition, continued to stir for 15 minutes to obtain dark gray Ag 2 CO 3 suspension;

[0069] 3) After raising the temperature of the water bath to 45°C, turn off the heating, and slowly add 60mL of formaldehyde to the suspension obtained in step 2). grayish-yellow earth color;

[0070] 4) After the reaction is over, let it stand still, and after the water powder is completely separated, remove the up...

Embodiment 2

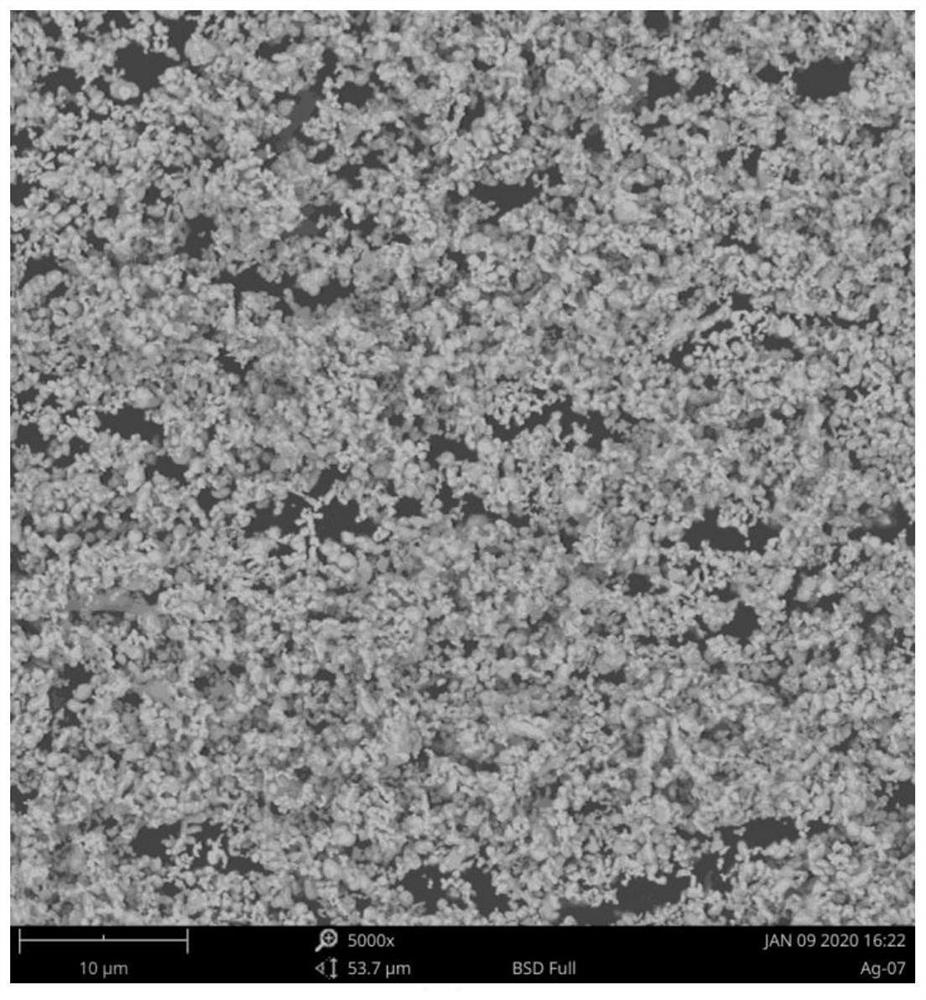

[0076] Embodiment 2: the preparation of spherical silver powder

[0077] 1) Preparation of silver nitrate (AgNO 3 ) solution: place a 2L beaker in a water bath at 40°C, inject 600mL deionized water into the beaker, and then add 200g AgNO 3 , turn on the mechanical stirring, wait for the AgNO 3 After complete dissolution, add dispersant and continue stirring for 10 minutes to obtain AgNO 3 aqueous solution;

[0078] 2) Preparation of Ag 2 CO 3 Suspension: Dissolve Na with 480mL deionized water 2 CO 3 Dissolved, and slowly added to the solution obtained in step 1), after the addition, continued to stir for 15 minutes to obtain dark gray Ag 2 CO 3 suspension;

[0079] 3) After heating the water bath to 45°C, turn off the heating, and slowly add 60mL of formaldehyde to the suspension obtained in step 2). grayish-yellow earth color;

[0080] 4) After the reaction is over, let it stand still, and after the water powder is completely separated, remove the upper clear layer...

Embodiment 3

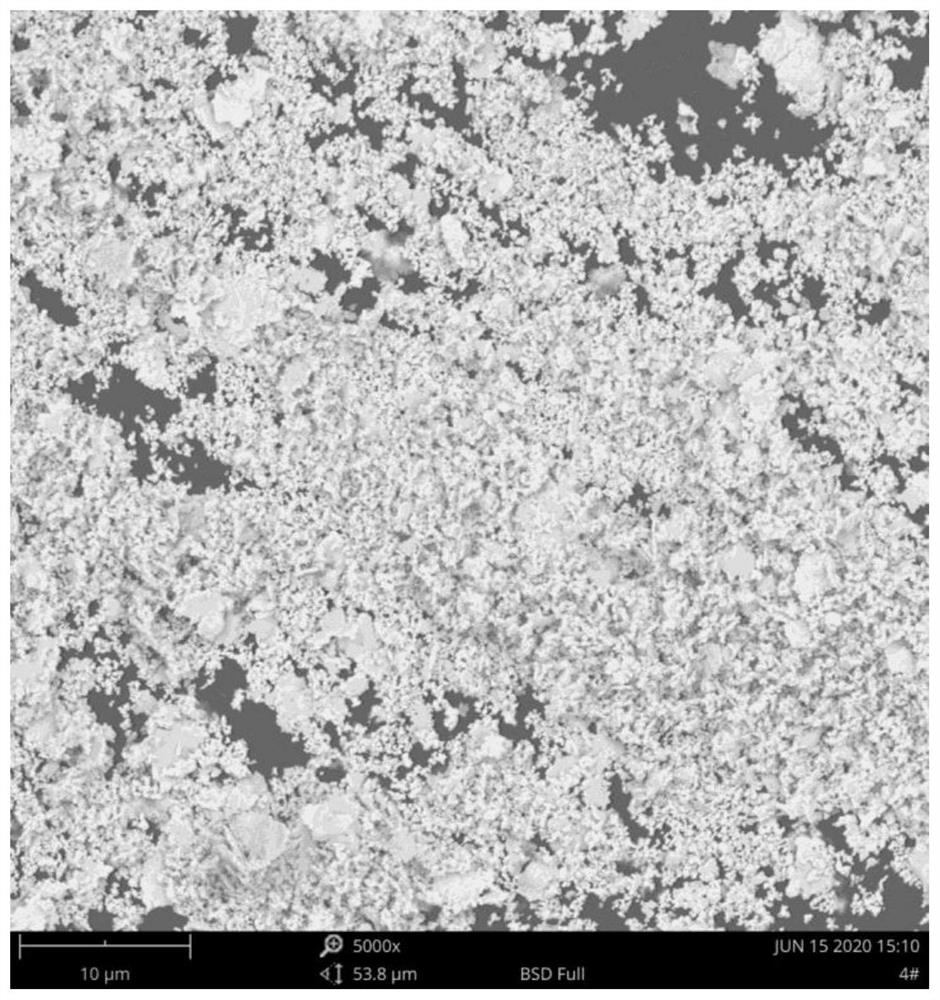

[0085] Embodiment 3: the preparation of part flaky silver powder

[0086] 1) Preparation of silver nitrate (AgNO 3 ) solution: place a 5L beaker in a water bath at 40°C, inject 1.5L deionized water into the beaker, and then add 200g AgNO 3 , turn on the mechanical stirring, wait for the AgNO 3 After complete dissolution, add dispersant and continue stirring for 10 minutes to obtain AgNO 3 aqueous solution;

[0087] 2) Preparation of Ag 2O suspension: Dissolve NaOH with 200mL deionized water, turn on the heating, and raise the temperature of the water bath to 55°C, then slowly add the NaOH solution to the solution obtained in step 1), as the reaction progresses, the color deepens, after the addition, continue Stir for 15min to get gray-black Ag 2 O suspension;

[0088] 3) Turn off the heating, slowly add 450g of triethanolamine to the suspension obtained in step 2), after the addition is complete, stir until the water and powder are separated, continue stirring for 15 min...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Conductivity | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com