Preparation method of nitrocotton-based solid alcohol

A solid alcohol, nitrocellulose-based technology is applied in the field of preparation of nitrocellulose-based solid alcohol, which can solve the problems of short burning time and poor toughness of solid alcohol, and achieve the effects of low cost, stable quality and uniform composition.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

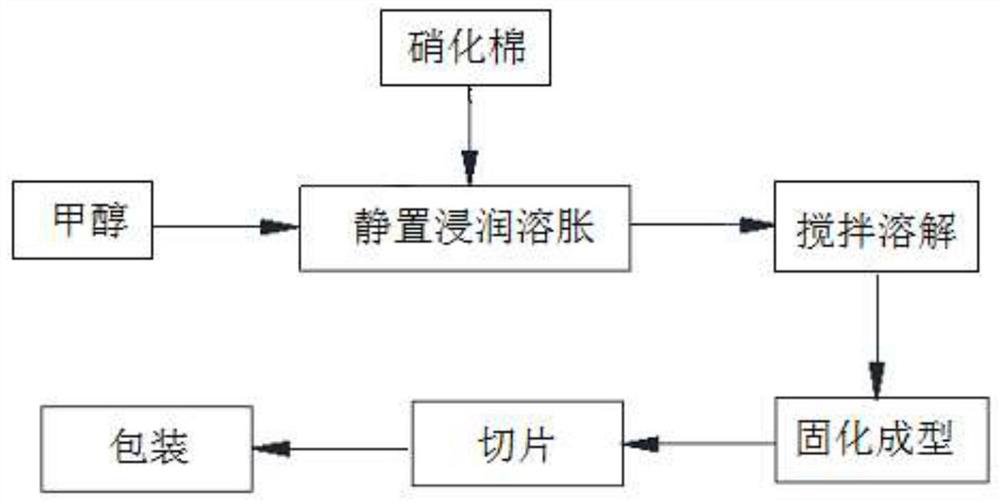

[0020] A kind of preparation method of nitrocellulose-based solid alcohol of the present invention, as figure 1 As shown, the specific steps are as follows:

[0021] Step 1, dissolving nitrocellulose: mix methanol with a mass concentration of 97% or more with nitrocellulose, let stand at room temperature for 30 to 120 minutes, then stir for 30 minutes to completely dissolve the nitrocellulose, and then add methanol with a mass concentration of 85% or more Methanol, stirred until completely dissolved again;

[0022] When dissolving for the first time, the mass ratio of nitrocellulose to methanol is 1:20;

[0023] When dissolving for the second time, the mass ratio of nitrocellulose to methanol is 1:30;

[0024] The viscosity of nitrocellulose is 500 seconds, which avoids the shortcomings of solid alcohol with too low viscosity, high hardness and poor toughness;

[0025] The water content of nitrocellulose is 25% to 35%, which reduces the cost compared with wine-containing ni...

Embodiment 1

[0031] Add 40 kg of methanol with a mass concentration of 97% in the stirred tank, add 2 kg of nitrocellulose (500 seconds) with a water content of 25% into the stirred tank, leave it for 30 min, and stir for 30 min to form a homogeneous solution, then add 95% of the mass concentration 20kg of methanol solution, stir until it is completely dissolved again; pour the dissolved homogeneous solution into a cylindrical permeable membrane to seal, stack and soak in water for 30 hours to solidify and form; take out the obtained cylindrical solid alcohol from the permeable membrane, slice The thickness is 2.5cm, and the sheet solid alcohol is packed into bags. The obtained solid alcohol was stored for 3 months without detaching, and 30 g of it was burned for 14.4 minutes in an open state, with no smoke and no peculiar smell, and the residue amount was 0.5%.

Embodiment 2

[0033] Add 40 kg of methanol with a mass concentration of 98% in the stirred tank, add 2 kg of nitrocellulose (500 seconds degree) with a water content of 30% into the stirred tank, leave it for 70 min, then stir for 30 min to form a homogeneous solution, then add 90% of the mass concentration 20kg of methanol solution, stir until it is completely dissolved again; pour the dissolved homogeneous solution into a cylindrical permeable membrane to seal, and once stacked and soaked in water for 20 hours to solidify and form; take out the obtained cylindrical solid alcohol from the permeable membrane and slice Thickness 2.0cm, flake solid alcohol packed into bags. The obtained solid alcohol was stored for 3 months without detaching, and 30 g of it was burned for 14.5 minutes in an open state, with no smoke and no peculiar smell, and the residue amount was 0.64%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com