Preparation method of heat-conducting textile material

A technology of textile materials and heat-conducting materials, which is applied in the field of preparation of heat-conducting textile materials, can solve problems such as unfavorable large-scale industrial production, impossibility of heat-conducting treatment, high cost of graphene, etc., and achieves convenient and easy-to-control operation process and low raw material consumption Less, enhance the effect of firmness and bonding force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] A method for preparing a heat-conducting textile material, specifically comprising the steps of:

[0026] A. cotton fabric pretreatment: dissolving dopamine in deionized water is configured into 2% dopamine solution, then the clean cotton fabric is placed in this dopamine solution, and the bath ratio of control cotton fabric and dopamine solution is 1:10, After 24 hours of ultrasonic vibration at room temperature, take it out and dry it;

[0027] B. Cotton fabric heat conduction treatment: on the surface of the cotton fabric gained in step A, utilize atomic layer deposition equipment to generate uniform, dense aluminum oxide heat conduction material coating; the deposition process is as follows:

[0028] Turn on the atomic layer deposition equipment, and alternately feed the pulses of the gaseous trimethylaluminum precursor and water precursor, wherein the exposure time of trimethylaluminum and water are 0.2s and 0.8s respectively, and the reaction time is 9.5s. The ga...

Embodiment 2

[0035] A method for preparing a heat-conducting textile material, specifically comprising the steps of:

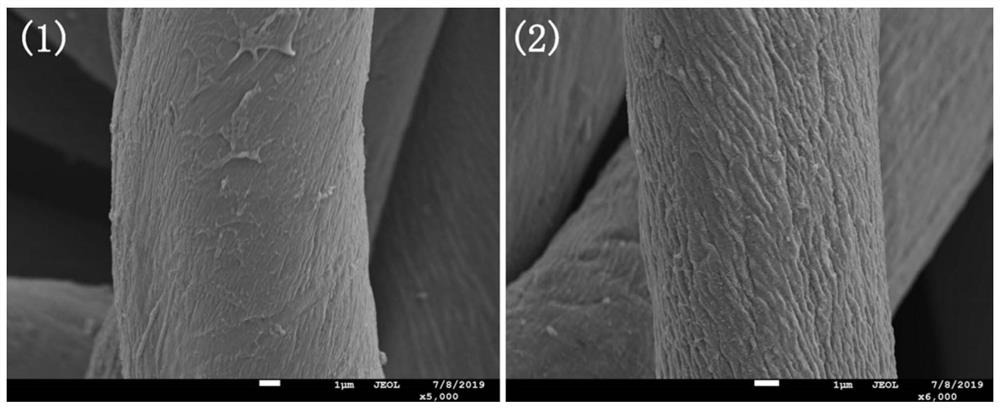

[0036] A. Polyester yarn pretreatment: dissolving dopamine in deionized water to form a 10% dopamine solution, then placing clean polyester yarn in the dopamine solution, and controlling the bath ratio of polyester yarn to dopamine solution to be 1 : 1, take out and dry after ultrasonic vibration at normal temperature for 12 hours;

[0037] B. heat conduction treatment of polyester yarn: on the surface of the polyester yarn obtained in step A, utilize atomic layer deposition equipment to generate a uniform and dense zinc oxide heat conduction material coating; the deposition process is as follows:

[0038] Turn on the atomic layer deposition equipment, and alternately feed gas-phase diethyl zinc precursor and water precursor pulses, wherein the exposure time of diethyl zinc and water are 0.05s and 0.15s, respectively, and the reaction time is 0.9s. The gas is all high-pur...

Embodiment 3

[0044] A method for preparing a heat-conducting textile material, specifically comprising the steps of:

[0045] A. Pretreatment of polyester filaments: dissolving dopamine in deionized water to form a 6% dopamine solution, then placing clean polyester filaments in the dopamine solution, and controlling the bath ratio of polyester filaments to dopamine solution to be 1 :5, take out and dry after ultrasonic vibration at normal temperature for 18h;

[0046] B. Polyester filament heat conduction treatment: on the surface of the polyester filament obtained in step A, utilize atomic layer deposition equipment to generate a uniform and dense aluminum nitride heat conduction material coating; the deposition process is as follows:

[0047] Turn on the atomic layer deposition equipment, and alternately feed the gas-phase aluminum trichloride precursor and ammonia precursor pulses, wherein the exposure time of aluminum trichloride and ammonia is 0.1s and 0.5s, and the reaction time is 3...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal conductivity | aaaaa | aaaaa |

| thermal conductivity | aaaaa | aaaaa |

| thermal conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com