Production process of ink-jet printing paper

A production process and inkjet printing technology, applied in the field of papermaking, can solve the problems of increasing production and use costs, smearing, slow drying speed, etc., and achieve the effect of improving the degree of bonding firmness, avoiding free diffusion, and improving the speed of absorption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

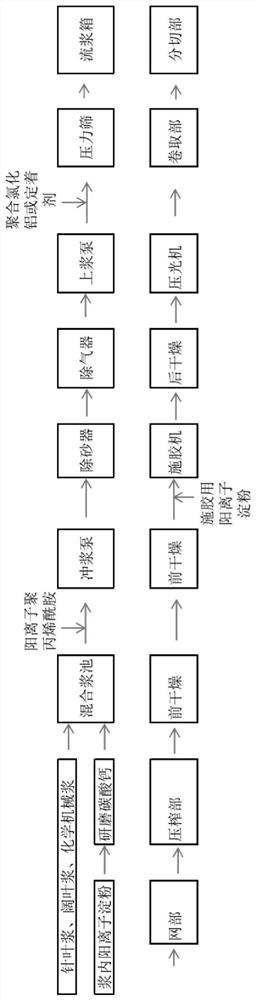

Image

Examples

Embodiment 1

[0043] A kind of production technology of ink-jet printing paper, concrete steps are as follows:

[0044] 1. Slurry ratio:

[0045] Bleached coniferous chemical pulp: accounting for 10%, beating concentration 4-5%, beating degree 28-32°SR;

[0046] Bleached broad-leaf chemical pulp: 80%, beating concentration 5-6%, beating degree 34-38°SR;

[0047] Bleached chemical mechanical pulp: accounted for 10%, beating concentration 3-4%, beating degree 30-32°SR.

[0048] 2. Other raw materials:

[0049] Grinding calcium carbonate: grade 65 (namely: more than 65% of particles with a particle size of ≤2um), solid content of 60%, dosage of 300kg / ton of paper;

[0050] Cationic starch for slurry: tapioca cationic starch or corn cationic starch, degree of substitution ≥ 0.04DS; dosage 55kg / ton of ground calcium carbonate;

[0051] Cationic starch for surface sizing: tapioca cationic starch or corn cationic starch, degree of substitution 0.02-0.03DS; dosage 60kg / ton of paper;

[0052] Cat...

Embodiment 2

[0071] A kind of production technology of ink-jet printing paper, concrete steps are as follows:

[0072] 1. Slurry ratio:

[0073] Bleached coniferous chemical pulp: accounting for 5%, beating concentration 4-5%, beating degree 28-32°SR;

[0074] Bleached broad-leaf chemical pulp: 90%, beating concentration 5-6%, beating degree 34-38°SR;

[0075] Bleached chemical mechanical pulp: accounting for 5%, beating concentration 3-4%, beating degree 30-32°SR.

[0076] 2. Other raw materials:

[0077] Grinding calcium carbonate: grade 65 (namely: more than 65% of particles with a particle size of ≤2um), solid content of 65%, dosage of 340kg / ton of paper;

[0078] Cationic starch for slurry: cationic starch of tapioca or cationic corn, degree of substitution ≥ 0.04DS; amount of 50kg / ton of ground calcium carbonate;

[0079] Cationic starch for surface sizing: tapioca cationic starch or corn cationic starch, degree of substitution 0.02-0.03DS; (because the cationic starch used for s...

Embodiment 3

[0092] A kind of production technology of ink-jet printing paper, concrete steps are as follows:

[0093] 1. Slurry ratio:

[0094] Bleached coniferous chemical pulp: accounting for 8%, beating concentration 4-5%, beating degree 28-32°SR;

[0095] Bleached broadleaf chemical pulp: 84%, beating concentration 5-6%, beating degree 34-38°SR;

[0096] Bleached chemical mechanical pulp: accounting for 8%, beating concentration 3-4%, beating degree 30-32°SR.

[0097] 2. Other raw materials:

[0098] Grinding calcium carbonate: grade 65 (namely: more than 65% of particles with a particle size of ≤2um), solid content of 63%, dosage of 350kg / ton of paper;

[0099] Cationic starch for slurry: tapioca cationic starch or corn cationic starch, degree of substitution ≥ 0.04DS; dosage 60kg / ton of ground calcium carbonate;

[0100] Cationic starch for surface sizing: tapioca cationic starch or corn cationic starch, degree of substitution 0.02-0.03DS; (because the cationic starch used for s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com