Electrode slurry in contact with p+ emitter of N-type solar cell

A solar cell and electrode paste technology, applied to conductive materials, circuits, electrical components, etc. dispersed in non-conductive inorganic materials, can solve problems such as increased volume resistance, burn-through, and large metal compounding, and achieve a balanced ohm Contact, enhance contact performance, reduce the effect of metal cladding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] An embodiment of the electrode slurry in contact with the p+ emitter of an N-type solar cell according to the present invention, the electrode slurry in this embodiment comprises the following components by weight:

[0035] 85 parts of conductive silver powder, 2 parts of aluminum powder, 5 parts of glass powder, 1 part of lanthanum aluminum alloy powder, 8 parts of organic carrier, 1 part of additive;

[0036] The weight ratio of spherical silver powder and nano-silver powder in the conductive silver powder is 4:1; the D50 particle diameter of spherical silver powder is 2 μm, and the D50 particle diameter of nano-silver powder is 100nm;

[0037] The activity of the aluminum powder is 99.0%, and the D50 particle size is 2 μm;

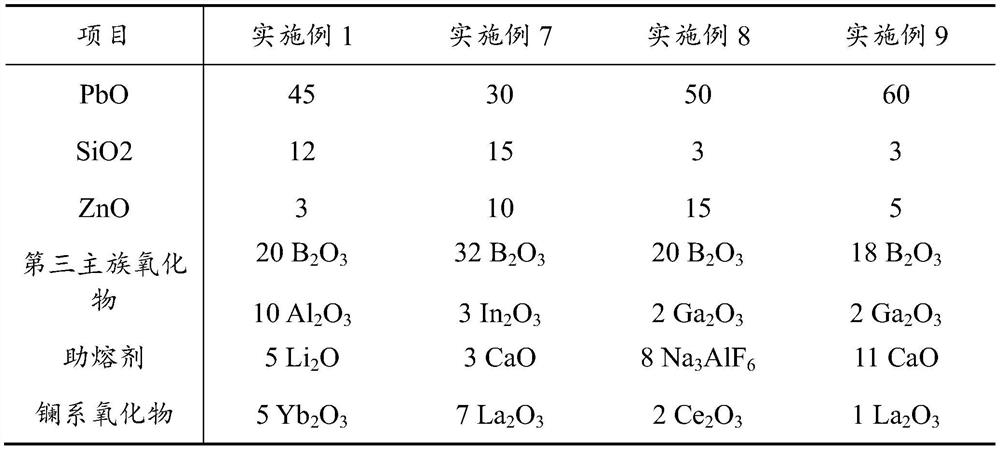

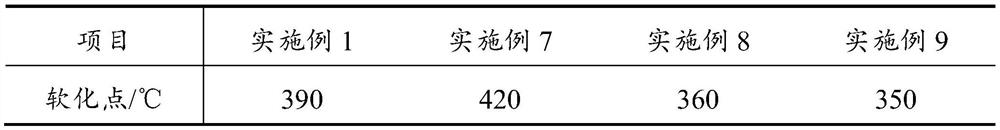

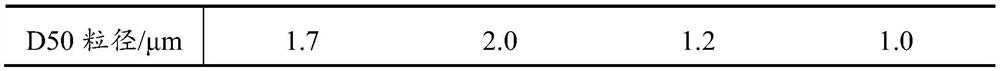

[0038] The formula of described glass powder is as shown in table 1;

[0039] The D50 particle size of the lanthanum aluminum alloy powder is 2 μm, and the mass fraction of aluminum is 99.5%;

[0040] The organic vehicle comprises alcohol ester...

Embodiment 2

[0046] An embodiment of the electrode slurry in contact with the p+ emitter of an N-type solar cell according to the present invention. In the electrode slurry described in this embodiment, except that the D50 particle size of the aluminum powder is 1 μm, all other formulas and preparation methods are the same. Same as Example 1.

Embodiment 3

[0048] An embodiment of the electrode slurry in contact with the p+ emitter of an N-type solar cell according to the present invention. In the electrode slurry described in this embodiment, except that the D50 particle size of the aluminum powder is 3 μm, all other formulas and preparation methods are the same. Same as Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com