Preparation method based on nano-porous independent electrode

An independent electrode and nanoporous technology, which is applied in hybrid capacitor electrodes, hybrid/electric double layer capacitor manufacturing, hybrid capacitor collectors, etc., can solve the problem of large volume changes of transition metal oxides, harsh operating conditions of fine control, and capacity decay speed Faster and other problems, to achieve the effect of increasing the rapid mass transfer process, enriching the effective redox reaction active sites, and accelerating the response kinetics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

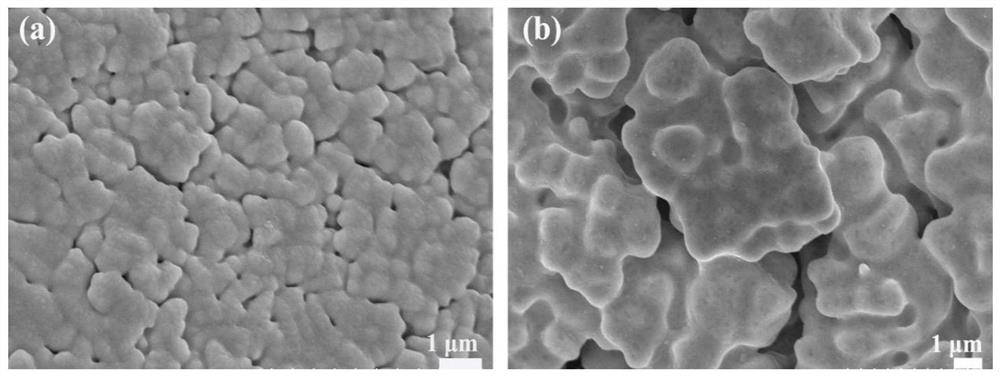

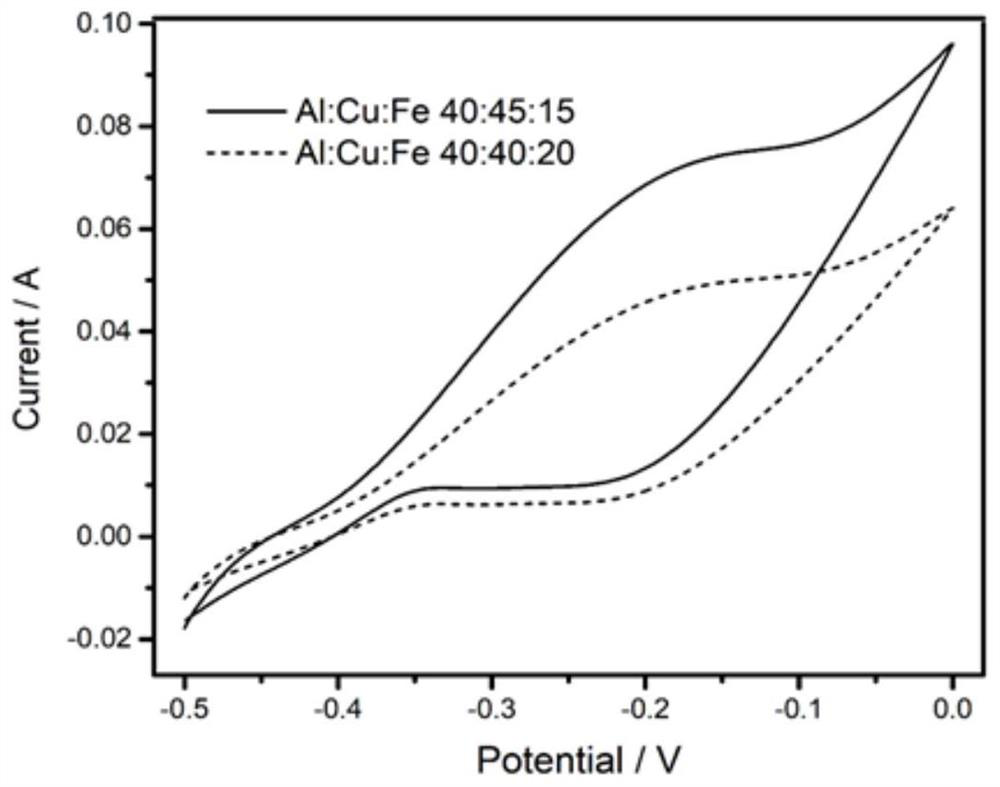

[0020] A method for preparing a nanoporous independent electrode, comprising the following steps:

[0021] (1) The metal particles of Al, Cu and Fe with a molar ratio of 8:9:3 and a purity of more than 99.99% are respectively placed in dilute Hcl solution for ultrasonic pickling to remove the oxide layer on the surface of the metal particles, and then put Dry in a vacuum drying oven to remove the oxide layer on the surface of the metal particles. In order not to corrode the metal particles during the pickling process and to effectively remove the oxide layer on the surface, as a preferred solution, dilute Hcl solution is selected for the pickling process. concentration of 0.001 M L-1, ultrasonic time of 30 min, and then vacuum drying, the conditions in the vacuum drying step are: vacuum degree of -10 Mpa, temperature of 70 ° C, drying time of 12 h, this condition does not affect the metal Oxidation occurs on the particle surface.

[0022] (2) Before smelting, put the metal Ti...

Embodiment 2

[0030] A method for preparing a nanoporous independent electrode, comprising the following steps:

[0031] (1) The metal particles of Al, Cu and Fe with a molar ratio of 8:9:3 and a purity of more than 99.99% are respectively placed in dilute Hcl solution for ultrasonic pickling to remove the oxide layer on the surface of the metal particles, and then put Dry in a vacuum drying oven to remove the oxide layer on the surface of the metal particles. In order not to corrode the metal particles during the pickling process and to effectively remove the oxide layer on the surface, as a preferred solution, dilute Hcl solution is selected for the pickling process. concentration of 0.001 M L-1, ultrasonic time of 30 min, and then vacuum drying, the conditions in the vacuum drying step are: vacuum degree of -10 Mpa, temperature of 70 ° C, drying time of 12 h, this condition does not affect the metal Oxidation occurs on the particle surface.

[0032] (2) Before smelting, put the metal Ti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com