A kind of negative electrode material of lithium ion battery and preparation method thereof

A technology for lithium-ion batteries and negative electrode materials, applied to battery electrodes, circuits, electrical components, etc., can solve the problems of poor high-rate charge and discharge performance, poor conductivity, etc., and achieve improved charge and discharge specific capacity, cycle stability, and production low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

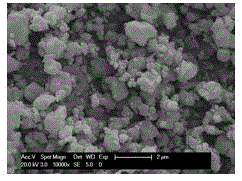

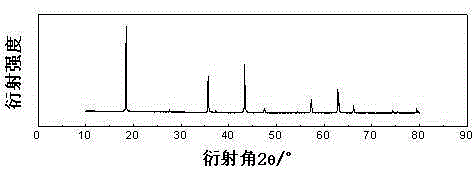

Image

Examples

preparation example Construction

[0043] 1. Preparation of negative pole piece:

[0044] The pure phase lithium titanate Li used in the embodiment 4 Ti 5 o 12 Or the negative electrode material of lithium ion battery, that is, the lithium titanate composite material coated with variable-valence metal oxide, conductive carbon black and binder polyvinylidene fluoride (PVDF) are mixed uniformly at a mass ratio of 90:10:10, and coated on copper Foil, dried and cut into negative pole pieces;

[0045] 2. Assembly of the button battery

[0046] With the above-mentioned negative electrode sheet as the negative electrode and lithium metal as the positive electrode, the electrolyte LiPF 6 The salt is dissolved in a mixed solution of ethylene carbonate (EC) / dimethyl carbonate (DMC) / ethyl methyl carbonate (EMC) with a mass ratio of 1:1:1 to form an electrolyte, and the concentration of the electrolyte is 1mol / L , assembled into coin cells in an argon glove box.

[0047] 3. Using the LAND battery test system to test ...

Embodiment 1

[0049] A lithium-ion battery negative electrode material, that is, a lithium titanate composite material coated with a variable-valence metal oxide, calculated on a molar ratio, wherein lithium in lithium titanate: metal in the variable-valence metal oxide is 4:0.03;

[0050] The variable price metal oxide is Co 3 o 4 .

[0051] The preparation method of above-mentioned a kind of lithium-ion battery negative electrode material, concrete steps are as follows:

[0052] After mechanically mixing 0.0241g of tricobalt tetroxide and 4.6g of pure-phase lithium titanate, add 10ml of anhydrous ethanol dispersant, ball mill on a ball mill for 2 hours, control the temperature at 80°C and continue to ball mill for 1 hour after vacuum drying to obtain the precursor;

[0053] Calculated according to the molar ratio, cobalt in tricobalt tetroxide: lithium in pure phase lithium titanate: absolute ethanol is 0.03:4:17;

[0054] Press the precursor on a powder tablet press to control the pre...

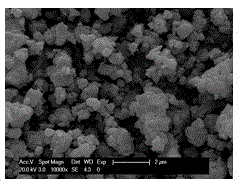

Embodiment 2

[0061] A lithium-ion battery negative electrode material, that is, a lithium titanate composite material coated with a variable-valence metal oxide, calculated on a molar ratio, wherein lithium in lithium titanate: metal in the variable-valence metal oxide is 4:0.02;

[0062] The variable price metal oxide is Cr 2 o 3 .

[0063] The preparation method of above-mentioned a kind of lithium-ion battery negative electrode material specifically comprises the following steps:

[0064]After mechanically mixing 0.08g of chromium nitrate and 4.6g of pure-phase lithium titanate, add 12ml of anhydrous ethanol dispersant, ball mill on a ball mill for 1h, control the temperature at 90°C and continue to ball mill for 0.5h after vacuum drying to obtain the precursor;

[0065] Calculated according to the molar ratio, that is, chromium in chromium nitrate: lithium in pure phase lithium titanate: absolute ethanol is 0.02:4:21;

[0066] Press the precursor on a powder tablet press to control ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com