Waste activated carbon regeneration method

An activated carbon and activation treatment technology, which is applied in separation methods, filter regeneration, chemical instruments and methods, etc., can solve the problems of environmental secondary pollution, scarcity of production resources, high price of activated carbon, etc., achieve enhanced regeneration efficiency, reduce production costs, The effect of high regeneration value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

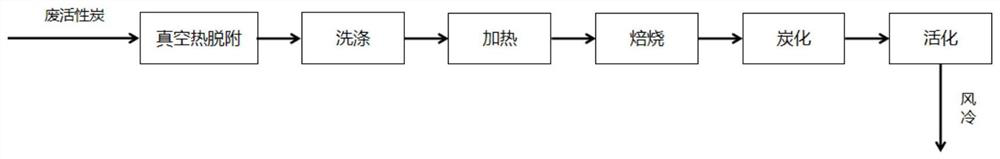

[0030] The method for regeneration of the waste activated carbon comprises the following steps:

[0031] Take out the saturated activated carbon and connect it to the vacuum thermal desorption device, start to raise the temperature and turn on the vacuum pump for desorption regeneration. During the desorption process, the vacuum degree is controlled at about 19kPa.

[0032] Starting from the initial desorption temperature (30°C), gradually increase the desorption temperature at intervals of 5°C, the interval time is 10 seconds, increase the desorption temperature to 90°C, and maintain the temperature at 90°C until the adsorption equilibrium state. At this time, the desorption rate of VOCs in activated carbon reaches 90%.

[0033] Wash the waste activated carbon with distilled water to ensure that visible impurities are cleaned, and dry at room temperature until the moisture content is 45%; this step is mainly to remove soluble substances;

[0034] Heat the cleaned wet charco...

Embodiment 2

[0042] The method for regeneration of the waste activated carbon comprises the following steps:

[0043] Take out the saturated activated carbon and connect it to the vacuum thermal desorption device, start to raise the temperature and turn on the vacuum pump for desorption regeneration. During the desorption process, the vacuum degree is controlled at about 19kPa.

[0044] Starting from the initial desorption temperature (30°C), gradually increase the desorption temperature at intervals of 5°C, the interval time is 10 seconds, raise the desorption temperature to 90°C, and maintain the temperature at 90°C to the adsorption equilibrium state , and the desorption rate of VOCs in activated carbon reaches 90%.

[0045] Wash the waste activated carbon with distilled water to ensure that visible impurities are cleaned, and dry at room temperature until the water content is 44%; this step is mainly to remove soluble substances;

[0046] Heat the cleaned wet charcoal at 110°C to evap...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com