A kind of using NdFeB solid waste to prepare nd 2 fe 14 The method of b/α-fe nanocomposite magnetic powder

A technology of nd2fe14b and solid waste, which is applied in the fields of magnetism of inorganic materials, manufacture of inductors/transformers/magnets, electrical components, etc., can solve the problems of reducing the significance of recycling NdFeB waste, consuming acid and organic solvents, complicated and lengthy processes, etc. Achieve high regeneration value, good thermal stability and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

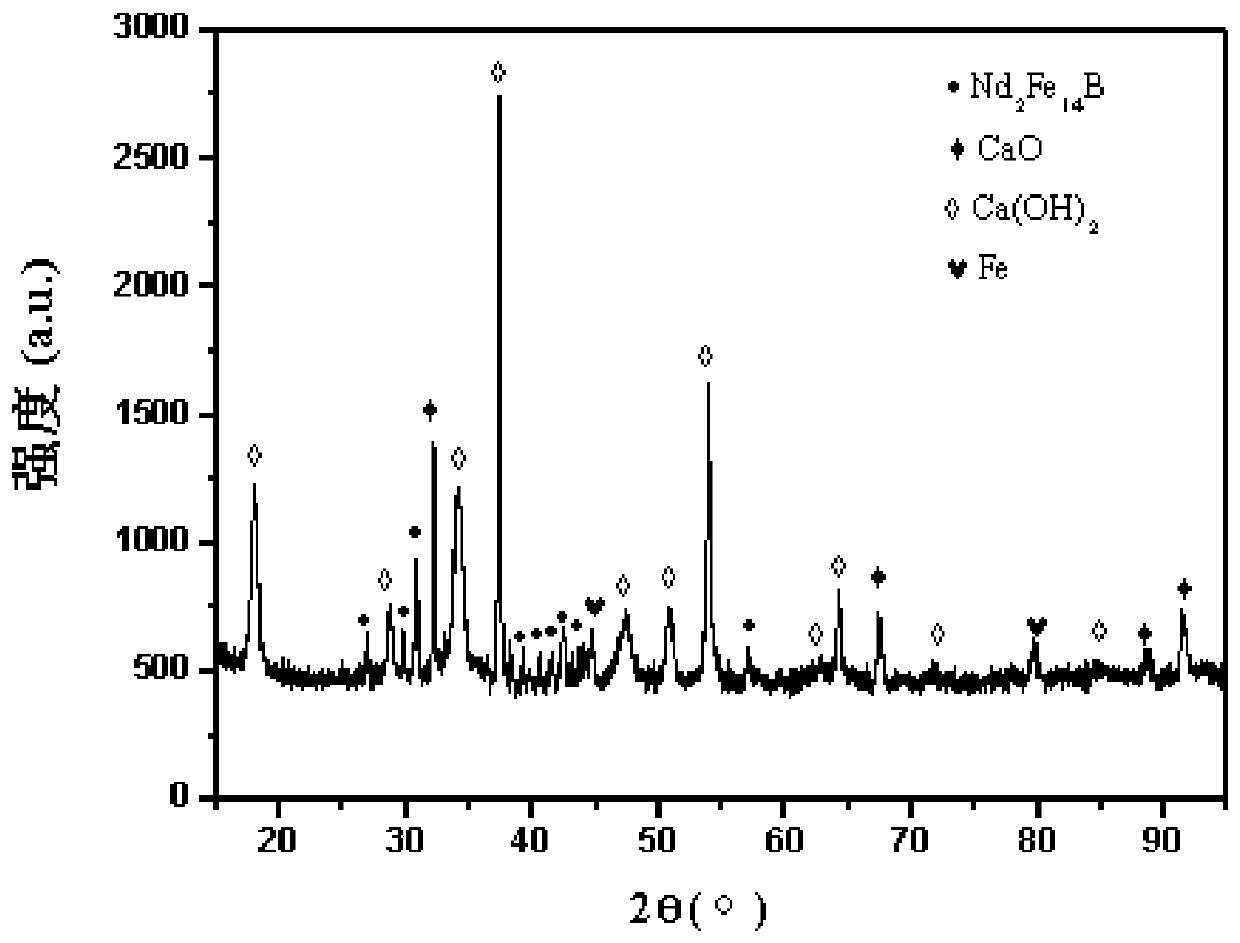

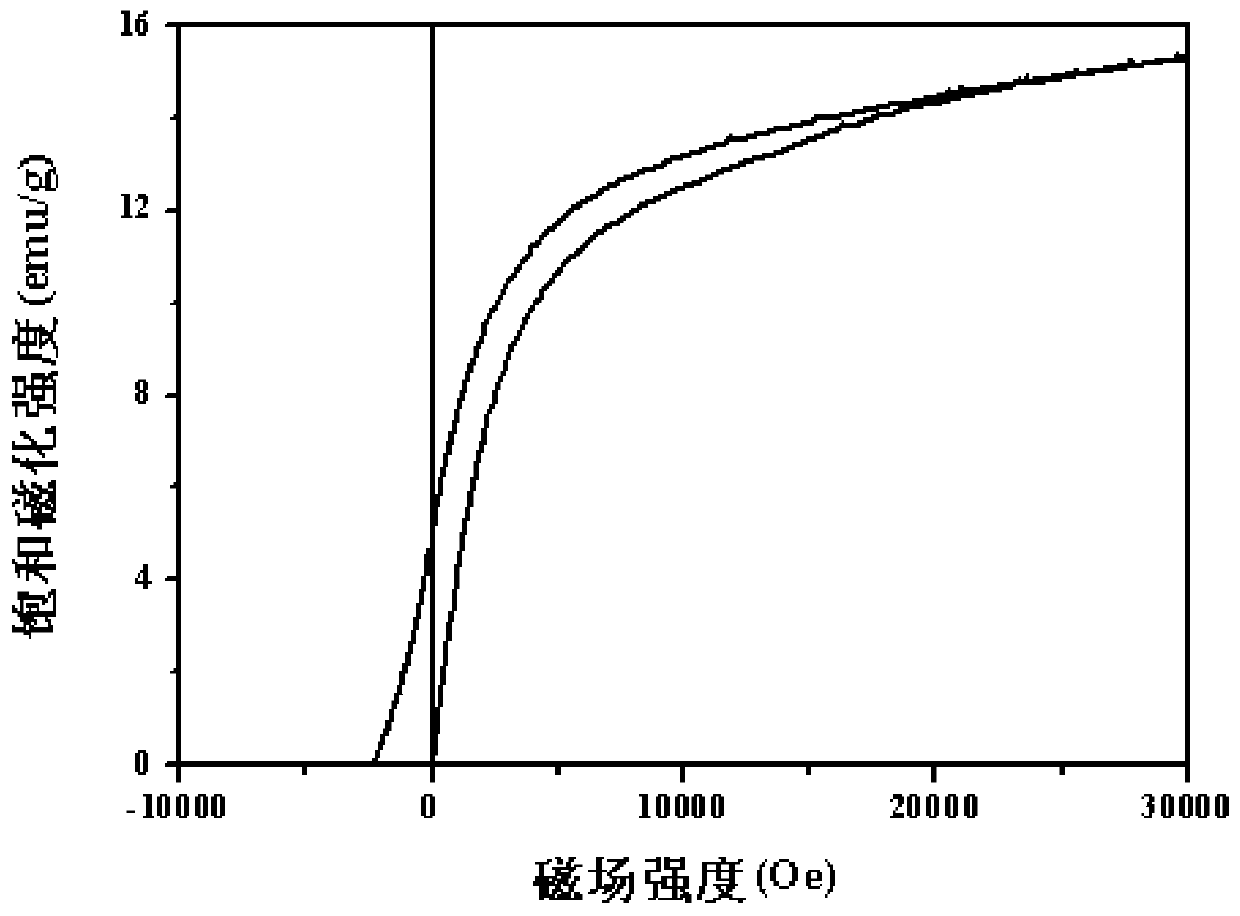

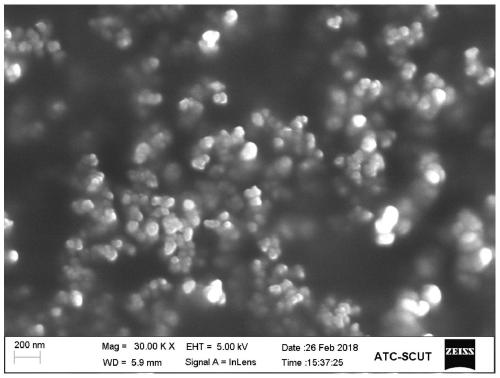

[0031] In this example, NdFeB solid waste was used as raw material to prepare regenerated NdFeB by microwave-assisted chemical synthesis. 2 Fe 14 B / α-Fe nanocomposite magnetic powder, the specific preparation steps are as follows:

[0032] (1) Take 3g of NdFeB solid waste, place them in 30ml ethanol solution and deionized water in turn, ultrasonically clean them for 10min, repeat 3 times; put the cleaned samples in a drying oven at 80°C, and dry for 1h; after drying The samples were pulverized into a powder with a particle size of <400 μm using a jet mill.

[0033] (2) Place the powder in step (1) in a beaker and add 4mol / L of HNO 3 50ml of the solution was fully dissolved, and the insoluble matter was filtered off; 3g of reducing agent glycine was added to the obtained solution, and stirred to fully dissolve; then the obtained solution was put into a microwave reactor with a power of 800W and reacted for 10min to obtain nanocrystalline mixed oxidation things.

[0034] (3)...

Embodiment 2

[0037] In this example, a certain amount of rare earth elements and boron elements are added according to the type and content of NdFeB solid waste elements, and the regenerated Nd is prepared by microwave-assisted chemical synthesis. 2 Fe 14 B / α-Fe nanocomposite magnetic powder, the specific preparation steps are as follows:

[0038] (1) Take 3g of NdFeB solid waste, place them in 30ml ethanol solution and deionized water in turn, ultrasonically clean them for 10min, repeat 3 times; put the cleaned samples in a drying oven at 80°C, and dry for 1h; after drying The samples were pulverized into a powder with a particle size of <400 μm by jet mill, and the element types and contents of the powder waste were analyzed;

[0039] (2) with Nd 15 Fe 77 B 8 Add a certain amount of Nd(NO 3 ) 3 and H 3 BO 3 . Put the mixed powder in a beaker and add 4mol / L HNO 3 50ml of the solution was fully dissolved, and the insoluble matter was filtered off; 3g of reducing agent glycine was...

Embodiment 3

[0046] In this example, NdFeB solid waste is used as raw material, and the regenerated Nd with high coercive force is synthesized by microwave-assisted chemical synthesis. 2 Fe 14 B / α-Fe nanocomposite magnetic powder. Concrete preparation steps are as follows:

[0047] (1) Take 3g of NdFeB solid waste, place them in 30ml ethanol solution and deionized water in turn, ultrasonically clean them for 10min, repeat 3 times; put the cleaned samples in a drying oven at 80°C, and dry for 1h; after drying The samples were pulverized into a powder with a particle size of <400 μm by jet mill, and the element types and contents of the powder waste were analyzed;

[0048] (2) with Nd 15 Fe 77 B 8 Add a certain amount of Nd(NO 3 ) 3 and H 3 BO 3 . Put the mixed powder in a beaker and add 4mol / L HNO 3 50ml of the solution was fully dissolved, and the insolubles were filtered off; 3g of the reducing agent glycine was added to the obtained solution, and stirred to fully dissolve it; ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com