Preparation method for carbon-encapsulated lithium ion battery cathode material LiFePO4/C

A lithium-ion battery, cathode material technology, applied in battery electrodes, circuits, electrical components, etc., can solve problems such as material performance degradation, and achieve the effects of improving electrochemical performance, improving electronic conductivity, and improving interface environment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0031] (1) Preparation of lithium iron phosphate electrode: adopt the obtained sample of the present invention as positive electrode material. Electron conductive material (acetylene black) and binder (polytetrafluoroethylene) are added during preparation. The ratio between the components is calculated by mass: positive electrode material of lithium ion battery: electronically conductive material: binder = 82:10:8.

[0032] (2) The negative electrode adopts metal lithium sheet.

[0033] (3) Battery assembly: The electrolyte uses ethyl carbonate: methyl ethyl carbonate: diethyl carbonate = 1:1:1 (wt%) as the solvent, and 1mol / L lithium hexafluorophosphorus (LiPF6 ) is the electrolyte of the electrolyte. The lithium iron phosphate electrode is used as the positive electrode, and the lithium sheet is used as the negative electrode to assemble the battery.

[0034] The cyclic voltammetry curve test of the present invention: the negative electrode lithium sheet is used as the co...

Embodiment 1

[0037] A preparation method of carbon-coated lithium-ion battery cathode material LiFePO4 / C, the steps are as follows:

[0038] First, add 5ml of deionized water to a 50ml ball mill jar, add 3.41ml of phosphoric acid and 2.6667g of ferric oxide, mix the materials evenly, and mill them on a ball mill for 2 hours, then add 0.9309g of iron powder and auxiliary reducing agent (1.09g Ascorbic acid or 1.6776g glucose) was ball milled for 2 hours, and finally 2.098g lithium hydroxide was added to continue ball milling on the ball mill for 2 hours to obtain the lithium iron phosphate precursor;

[0039] The precursor is calcined at a temperature of 600-800° C. for 5 hours under the protection of an inert gas N2 to obtain LiFePO4 / C, which are respectively ascorbic acid and glucose-coated cathode composite materials for lithium-ion batteries.

Embodiment 2

[0041] The preparation method of lithium-ion battery cathode material LiFePO without adding auxiliary reducing agent, the steps are as follows:

[0042]First, add 5ml of deionized water to a 50ml ball mill jar, add 3.41ml of phosphoric acid and 2.6667g of ferric oxide, mix the materials on a ball mill for 2 hours, then add 0.9309g of iron powder and continue to mill for 2 hours, and finally add 2.098 g lithium hydroxide continues to be milled on the ball mill for 2 hours to obtain the lithium iron phosphate precursor;

[0043] The precursor is calcined at a temperature of 600-800° C. for 5 hours under the protection of an inert gas to obtain the positive electrode material of lithium ion battery --- the lithium ion battery positive electrode material LiFePO4 without carbon coating.

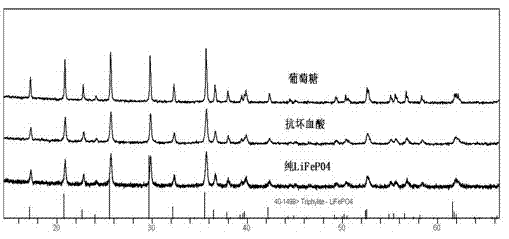

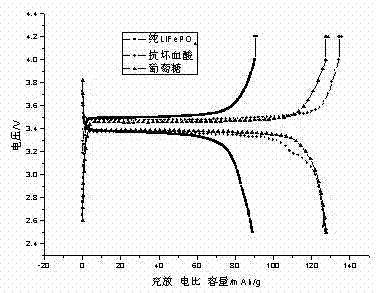

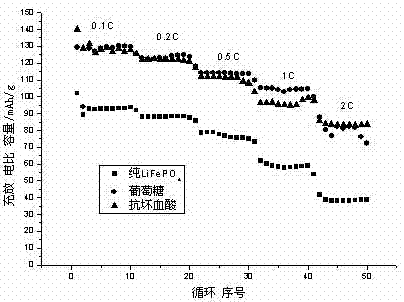

[0044] figure 1 It is the XRD test result of the lithium ion battery positive electrode material LiFePO4 / C that is respectively ascorbic acid and glucose that are carried out carbon coating in em...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com