Composition containing precipitated theta iron carbide, preparation method of composition, catalyst, application of catalyst, and Fischer-Tropsch synthesis method.

A Fischer-Tropsch synthesis and composition technology, which is used in the preparation of liquid hydrocarbon mixtures, catalysts for physical/chemical processes, chemical instruments and methods, etc. The effect of low CO2 selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0045] In a preferred embodiment of the present invention, the drying and roasting process includes: first drying the solid at a temperature of 35-80°C and a vacuum of 250-1200Pa for 6-10 hours; Dry at 75-180°C for 3-24h, and then roast the obtained material at 250-580°C for 1-10h. The above drying process can be performed in an oven, and the roasting process can be performed in a muffle furnace.

[0046] In some embodiments of the present invention, step (2) can simultaneously generate nano-iron powder in situ from the iron element in the precursor and reduce the generated nano-iron powder.

[0047] In some embodiments of the present invention, H in step (2) 2 Can be H 2 The form of flow is passed into the reaction system, and at the same time, by controlling the H 2 Flow pressure to control the pressure of the precursor reduction, preferably, in step (2), the pressure of the precursor reduction is 0.1-15atm, preferably 0.3-2.6atm, and the time is 0.7-15h, preferably 1-12h...

Embodiment 1

[0084] (1) Mix ferric nitrate with a concentration of 1.2mol / L and 0.9mol / L sodium carbonate solution at 55°C and pH=6.2 to obtain a precipitated slurry, wash with deionized water, filter to obtain a filter cake, and dry at 110°C 24h, 400°C calcined for 10h to obtain the precursor.

[0085] (2) Combine the precursor with H 2 At a pressure of 2.6atm, H 2 The flow rate is 22000mL / h / g, and the precursor reduction is carried out at a temperature of 470°C for 12h;

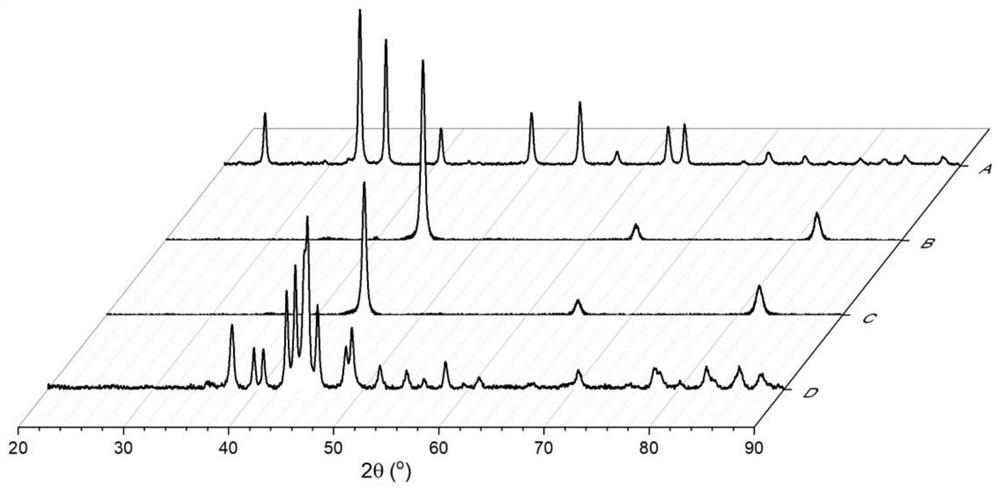

[0086] (3) Cool the product obtained in step (2) from 470°C to 400°C at a rate of 1.5°C / min, and mix with H at this temperature 2 Contact with CO mixed gas to prepare precipitated carbides, the conditions are: pressure 20atm, total gas flow 20000mL / h / g, H 2 The molar ratio to CO is 60:1, and the treatment time is 24 hours to obtain precipitated iron carbide, which is determined as pure θ iron carbide by Mössbauer spectroscopy, which is recorded as iron carbide 1;

[0087] (4) Under the protection of Ar gas, mix 97 m...

Embodiment 2

[0089] (1) Mix the ammonium carbonate solution with a concentration of 1.3mol / L ferric ammonium citrate and 0.7mol / L at 65°C and pH=6.9 to obtain a precipitated slurry, wash with deionized water, and filter to obtain a filter cake, 110 ℃ drying for 24 hours, and 300 ℃ calcination for 10 hours to obtain the precursor.

[0090] (2) Combine the precursor with H 2 At a pressure of 0.3atm, H 2 The flow rate is 2800mL / h / g, and the precursor reduction is carried out at a temperature of 620°C for 1h;

[0091] (3) Cool the product obtained in step (2) from 620°C to 300°C at a rate of 1.5°C / min, and mix with H at this temperature 2 Contact with CO mixed gas to prepare precipitated carbides, the conditions are: pressure 0.01atm, total gas flow 1200mL / h / g, H 2 The molar ratio to CO is 60:1, and the treatment time is 80h, to obtain precipitated iron carbide, which is determined as pure θ iron carbide by Mössbauer spectroscopy, which is recorded as iron carbide 2;

[0092] (4) Under the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com