A highly weather-resistant architectural exterior coating

A technology with high weather resistance and construction, applied in the direction of coating, polyester coating, etc., can solve the problems of high equipment requirements, complicated process, high cost, etc., and achieve the effect of strong anti-ultraviolet, strong hiding ability, and strong anti-yellowing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

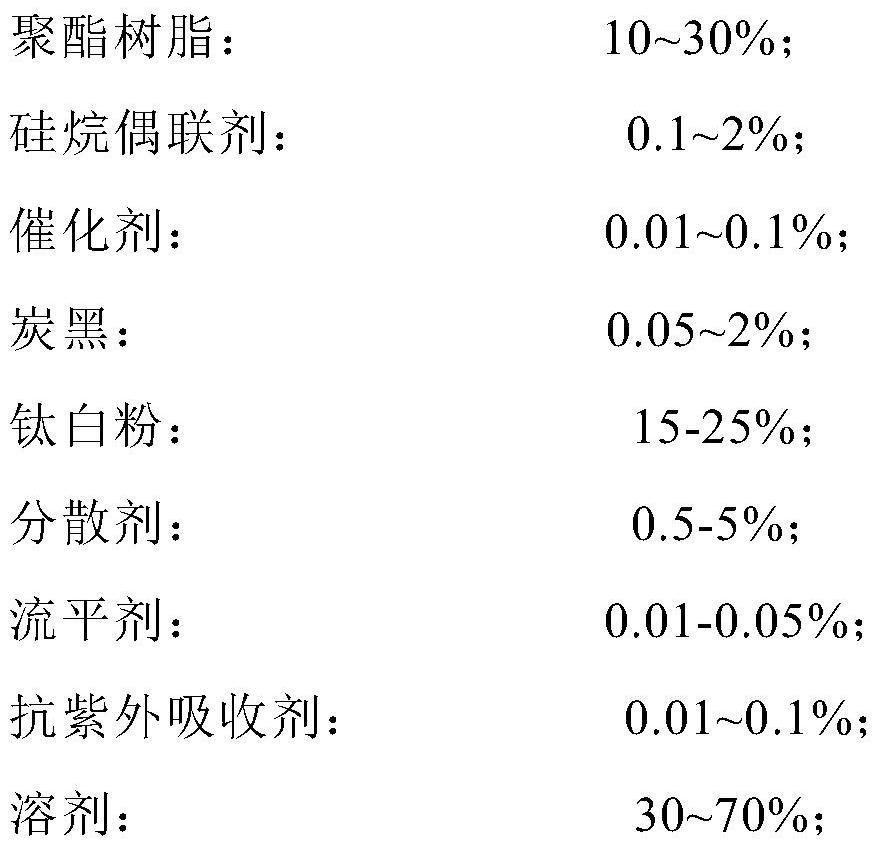

Method used

Image

Examples

Embodiment 1

[0045] A preparation method for component A of a high weather-resistant architectural coating for metal building exterior walls, comprising the following process steps:

[0046] (1) Mix 1% ester dispersant, 2% ethyl acetate, and 5% aliphatic saturated polyester resin, disperse at high speed for 1 hour, then slowly add 2% carbon black, disperse at high speed for 1 hour, and obtain black slurry;

[0047] (2) Mix 4% ester dispersant, 25% ethyl acetate, and 25% aliphatic saturated polyester resin, disperse at high speed for 1 hour, then slowly add 25% rutile titanium dioxide, disperse at high speed for 1 hour, and get white pulp;

[0048] (3) Place the dispersed black slurry and white slurry in a sand mill for grinding for 15 minutes at a speed of 2000r / min;

[0049] (4) Mix the ground color paste, add 2% epoxy silane coupling agent, 0.05% organosiloxane leveling agent, 0.1% salicylate anti-ultraviolet absorber, 0.1% organic bismuth catalyst , supplemented with 8.75% ethyl aceta...

Embodiment 2

[0052] A preparation method for component A of a high weather-resistant architectural coating for metal building exterior walls, comprising the following process steps:

[0053] (1) Mix 0.05% ester dispersant, 3% ethyl acetate, and 3% aromatic saturated polyester resin, disperse at high speed for 1 hour, then slowly add 0.05% carbon black, disperse at high speed for 1 hour, and obtain black slurry;

[0054] (2) Mix 0.45% ester dispersant, 30% ethyl acetate, and 12% aromatic saturated polyester resin, disperse at high speed for 1 hour, then slowly add 15% rutile titanium dioxide, disperse at high speed for 1 hour, and get white pulp;

[0055] (3) Place the dispersed black slurry and white slurry in a sand mill for grinding for 15 minutes at a speed of 2000r / min;

[0056](4) Mix the ground color paste, add 0.1% epoxy silane coupling agent, 0.01% organosiloxane leveling agent, 0.01% hindered amine anti-ultraviolet absorber, 0.01% organic bismuth catalyst, 36.32% ethyl acetate, ...

Embodiment 3

[0059] A preparation method for component A of a high weather-resistant architectural coating for metal building exterior walls, comprising the following process steps:

[0060] (1) Mix 0.5% ester dispersant, 2.5% ethyl acetate, and 3.5% aromatic saturated polyester resin, disperse at high speed for 1 hour, then slowly add 1% carbon black, disperse at high speed for 1 hour, and obtain black pulp;

[0061] (2) Mix 2.5% ester dispersant, 27.5% ethyl acetate, and 16.5% aromatic saturated polyester resin, disperse at high speed for 1 hour, then slowly add 20% anatase titanium dioxide, disperse at high speed for 1 hour, and obtain white paste;

[0062] (3) Place the dispersed black slurry and white slurry in a sand mill for grinding for 15 minutes at a speed of 2000r / min;

[0063] (4) Mix the ground color paste, add 1% methoxysilane coupling agent, 0.03% organosiloxane leveling agent, 0.05% benzophenone anti-ultraviolet absorber, 0.05% organotin catalyst, 24.87% ethyl acetate, af...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com