Online centralized continuous annealing method and annealing equipment for wire drawing machine

A technology of annealing equipment and wire drawing machine, applied in the field of wire rod manufacturing, can solve the problems of unsatisfactory annealing effect, complex structure of wire drawing machine, large volume, etc., to achieve the effect of improving annealing effect, increasing ductility and toughness, and simplifying the overall structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

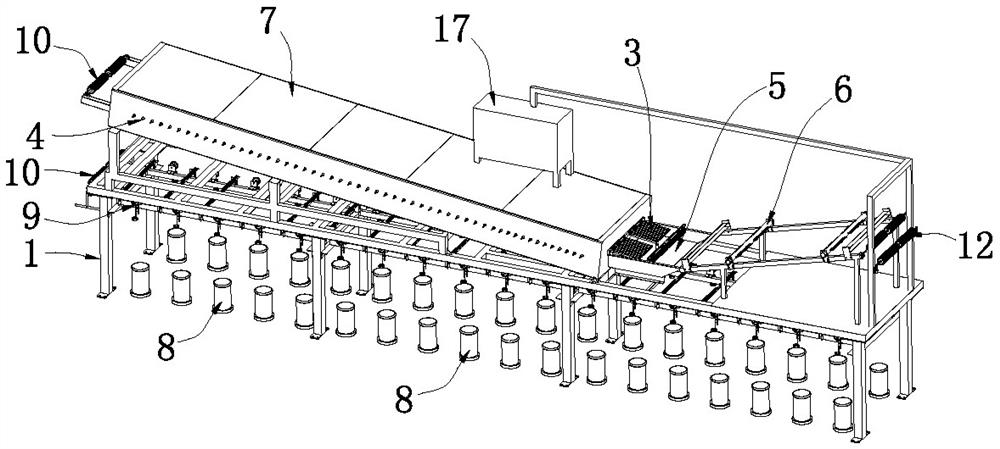

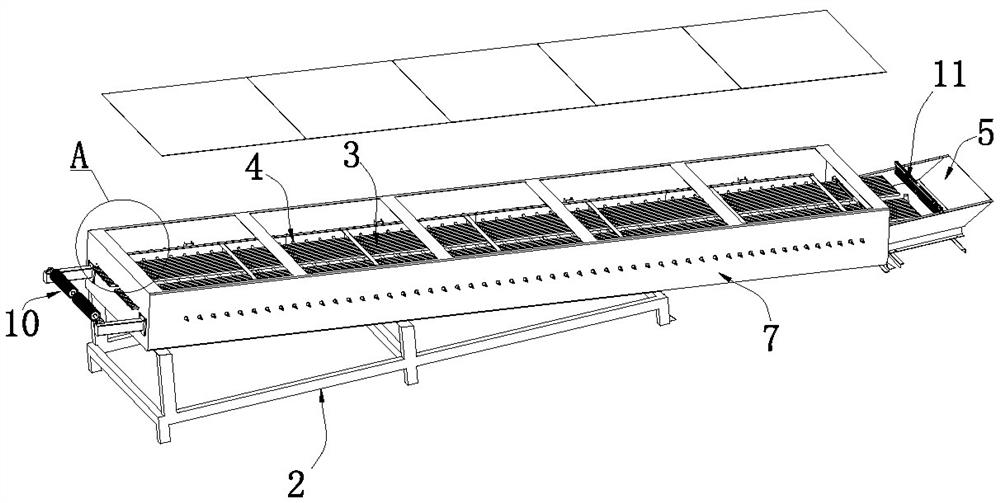

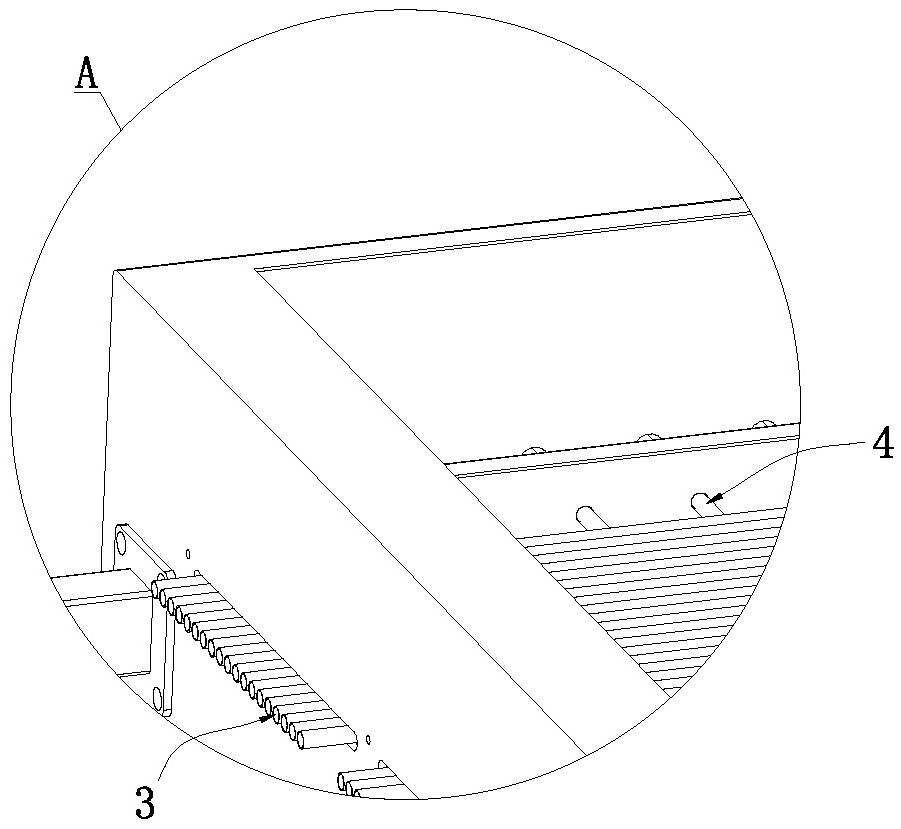

[0033] Example: See Figure 1 to 6 The present embodiment provides a briger online centralized continuous annealing apparatus including a frame 1, a tilt bracket 2, a softening steel tube 3, a heating device 4, a water tank 5, and a dewatering device 6, the inclined bracket 2, a sink 5 And the dewatering device 6 is arranged in sequentially disposed on the frame 1, and several softening steel pipes 3 are arranged in parallel to the inclined bracket 2 such that one end of the softening steel tube 3 extends into the water tank 5, i.e., softening steel tube 3 The end of the entry extends into the sink 5, and the end is not inlet, and the other end of the softening steel tube 3 extends upward. The heating device 4 is located next to the softening steel tube 3 and can heat the softening steel tube 3. The softening steel tube 3 is preferably a stainless steel tube.

[0034] An annealed bracket 2 is provided with an annealed box 7, and the heating device 4 is an electric tube that is loca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com