Air-cooled fuel cell system

A fuel cell system and fuel cell technology, applied in fuel cells, fuel cell additives, fuel cell heat exchange, etc., can solve problems such as the impact of fuel cell performance that is difficult to solve, and achieve the goal of being suitable for large-scale production, the system is simple, the Effects that are easy to operate and control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

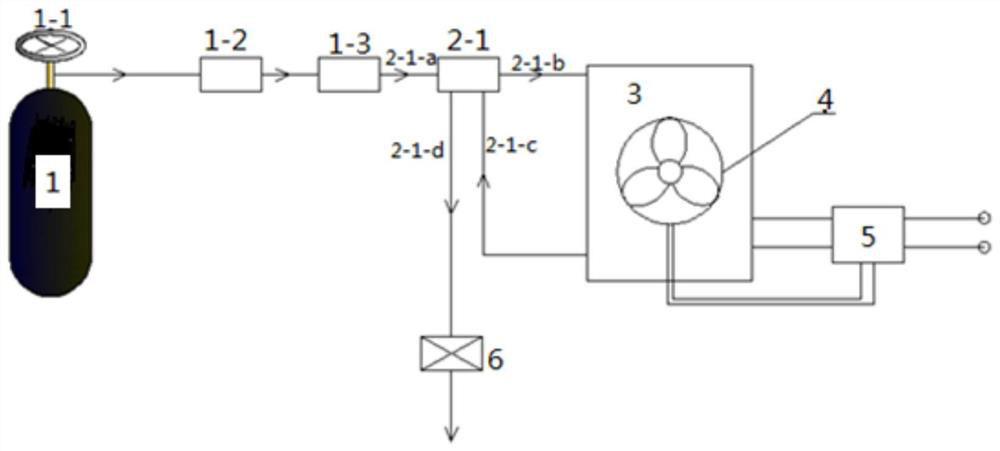

[0036] Such asfigure 1 As shown, a common steel cylinder with a volume of 40 liters and a pressure of 12 MPa is selected as the gas source, Baode solenoid valve and SMC regulator valve are selected, a self-made membrane humidifier and tail solenoid valve are selected, and 29 air-cooled fuel cells are self-made Electric stack and axial flow fan, the performance test of the fuel cell, the results are as follows Figure 5 shown. At a room temperature of 22°C and a relative humidity of 46%, using hydrogen as fuel, when the hydrogen partial pressure (gauge pressure) is 0.05MPa, and using air cooling for heat dissipation, the current density reaches 0.6A / cm 2 , the output power reaches 970W.

Embodiment 2

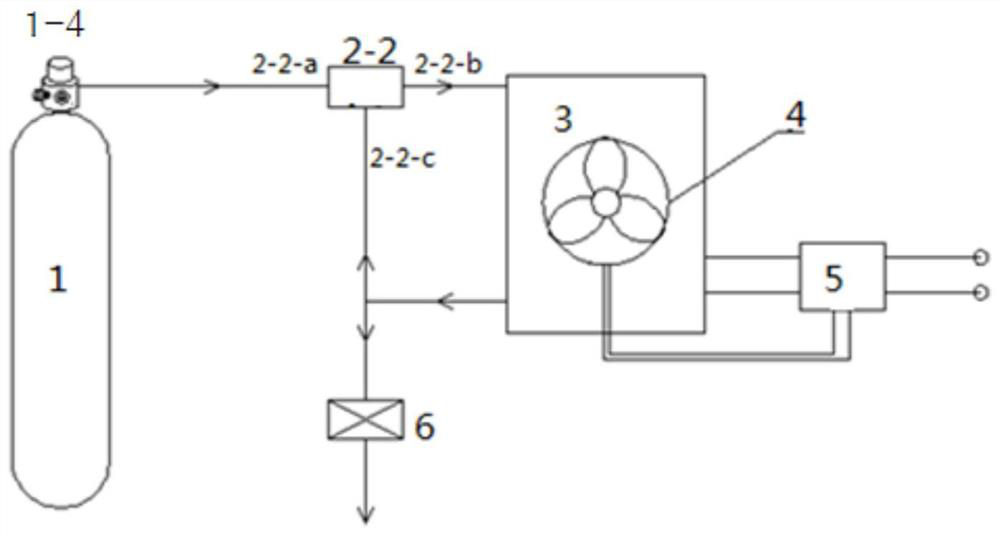

[0038] Such as figure 2 As shown, a carbon fiber-wound aluminum alloy bottle with a volume of 9 liters and a pressure of 35 MPa is selected as the gas and hydrogen source, in which the bottle valve, the gas source switch valve and the pressure regulator valve are an integrated structure, and a self-made ejector and tail exhaust are selected. Solenoid valve, self-made 32-section air-cooled fuel cell stack and axial fan, the performance test of the stack, the results are as follows Figure 6 shown. At a room temperature of 24°C and a relative humidity of 52%, using hydrogen as fuel, when the hydrogen partial pressure (gauge pressure) is 0.05MPa, and using air cooling for heat dissipation, the current density reaches 0.65A / cm2, and the output power reaches 1250W.

Embodiment 3

[0040] In order to test the stability of the fuel cell system except for the gas cylinder, the centralized pipeline in the laboratory is selected to continuously supply hydrogen to meet the demand for hydrogen consumption. The emergency manual switch valve and SMC pressure regulator valve are used, and the self-made ejector and tail solenoid valve are used. , self-made 32 air-cooled fuel cell stacks and axial fans to test the stability of fuel cells. The result is as Figure 7 shown. When the room temperature range is 22-25°C and the relative humidity range is 36-70%, hydrogen is used as fuel, when the hydrogen partial pressure (gauge pressure) in the stack is 0.05MPa, and when air cooling is used for heat dissipation, the current density reaches 0.65A / cm 2 , the output power reaches 1240W, and the performance has not been attenuated after 200 hours of continuous operation.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com