Antibacterial preservative film and preparation process thereof

A technology of fresh-keeping film and base layer, which is applied in the field of antibacterial fresh-keeping film and its preparation technology, can solve the problems that the fresh-keeping film does not have antibacterial effect, the fresh-keeping film does not have antibacterial effect, and affects the preservation time of food, so as to prevent the production and reproduction, Improved bactericidal and antibacterial effect, strong practical effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

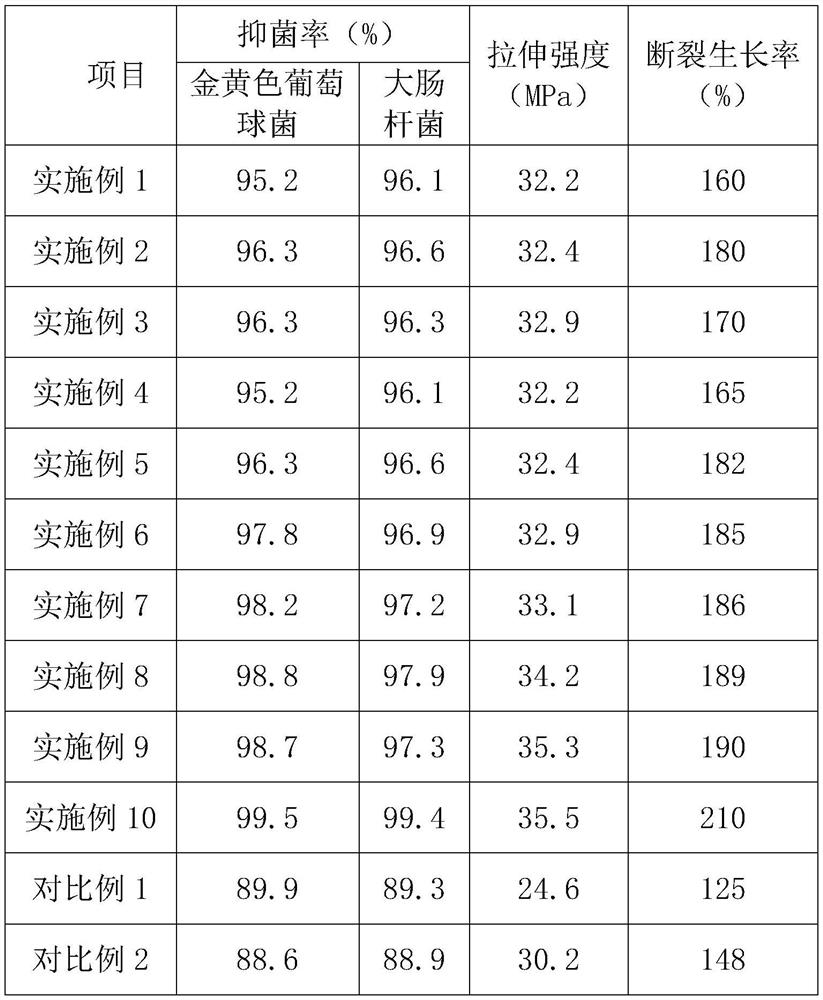

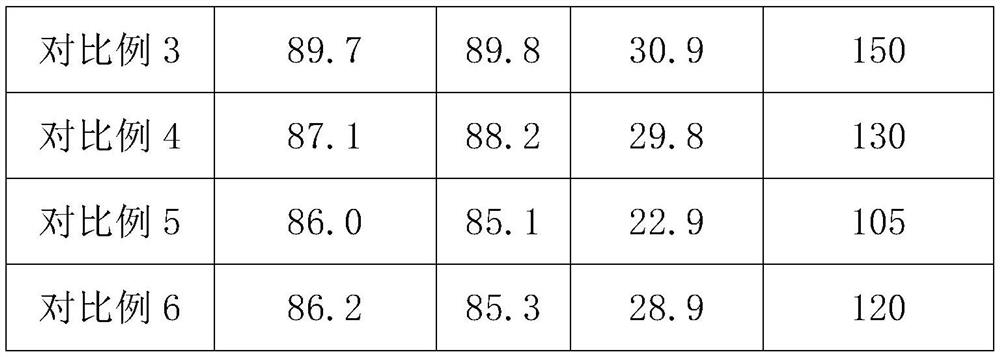

Examples

Embodiment 1

[0056] Adopt following preparation technology according to the application to produce antibacterial fresh-keeping film:

[0057] 2kg low-density high-pressure polyethylene, 96kg high-density low-pressure polyethylene, 1kg silver-loaded silicate, 3kg propylparaben, 1kg chitin, 0.4kg nisin, 6kg edible gelatin, 0.5kg hydrotalcite, 0.3 kg activated carbon (1000 mesh) was kneaded for 20min at a temperature of 200° C. to form the first grass-roots mixture and the second grass-roots mixture respectively;

[0058] 2kg low-density high-pressure polyethylene, 96kg high-density low-pressure polyethylene, 1kg silver-loaded silicate, 2kg ethyl vanillin, 1kg chitin, 3kg edible gelatin, 0.3kg hydrotalcite, 0.1kg activated carbon (1250 mesh) Kneading at a temperature of 240°C for 15 minutes to form the first stable layer mixture and the second stable layer mixture;

[0059] Mix 94kg of high-density low-pressure polyethylene, 6kg of silver-loaded silicate, 2kg of edible gelatin, 0.3kg of hydr...

Embodiment 2

[0062] Adopt following preparation technology according to the application to produce antibacterial fresh-keeping film:

[0063] 10kg low-density high-pressure polyethylene, 85kg high-density low-pressure polyethylene, 6kg silver-loaded silicate, 2kg propylparaben, 3kg chitin, 0.2kg nisin, 8kg edible gelatin, 0.2kg hydrotalcite, 0.1 kg activated carbon (1000 mesh) was kneaded at a temperature of 200° C. for 20 minutes to form the first base layer mixture and the second base layer mixture respectively;

[0064] 10kg low-density high-pressure polyethylene, 85kg high-density low-pressure polyethylene, 6kg silver-loaded silicate, 3kg ethyl vanillin, 3kg chitin, 6kg edible gelatin, 0.1kg hydrotalcite, 0.3kg activated carbon (1250 mesh) Knead at a temperature of 240°C for 15 minutes to form the first stable layer mixture and the second stable layer mixture; 99kg high-density low-pressure polyethylene, 1kg silver-loaded silicate, 2kg edible gelatin, 0.3kg hydrotalcite, 0.1 kg activa...

Embodiment 3

[0067] Adopt following preparation technology according to the application to produce antibacterial fresh-keeping film:

[0068] 6kg low-density high-pressure polyethylene, 90kg high-density low-pressure polyethylene, 3kg silver-loaded silicate, 2.5kg propylparaben, 2kg chitin, 0.3kg nisin, 7kg edible gelatin, 0.4kg hydrotalcite, 0.2kg of activated carbon (1250 mesh) was kneaded at a temperature of 240° C. for 15 minutes to form the first base layer mixture and the second base layer mixture;

[0069] 8kg low-density high-pressure polyethylene, 92kg high-density low-pressure polyethylene, 3kg silver-loaded silicate, 1.5kg ethyl vanillin, 2kg chitin, 4kg edible gelatin, 0.2kg hydrotalcite, 0.2kg activated carbon (1000 mesh) Knead at a temperature of 200°C for 20 minutes to form the first stable layer mixture and the second stable layer mixture; 96kg high-density low-pressure polyethylene, 5kg silver-loaded silicate, 3kg edible gelatin, 0.2kg hydrotalcite, 0.25kg of activated ca...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com