Zero-emission treatment method and system for landfill leachate

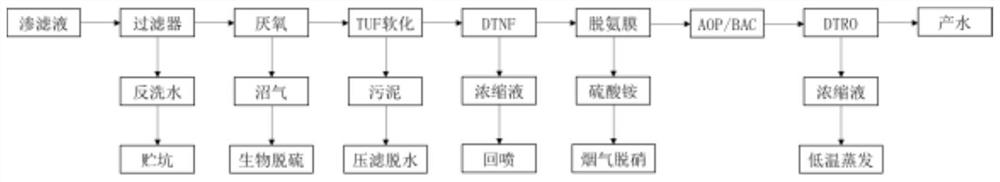

A landfill leachate and treatment method technology, which is applied in the field of landfill leachate zero-discharge treatment methods and systems, can solve the problems of easy fouling and fouling of membranes, large volume of membrane concentrates that are difficult to handle, and high A/O operation requirements. Small footprint, good promotion prospects, and efficient treatment effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

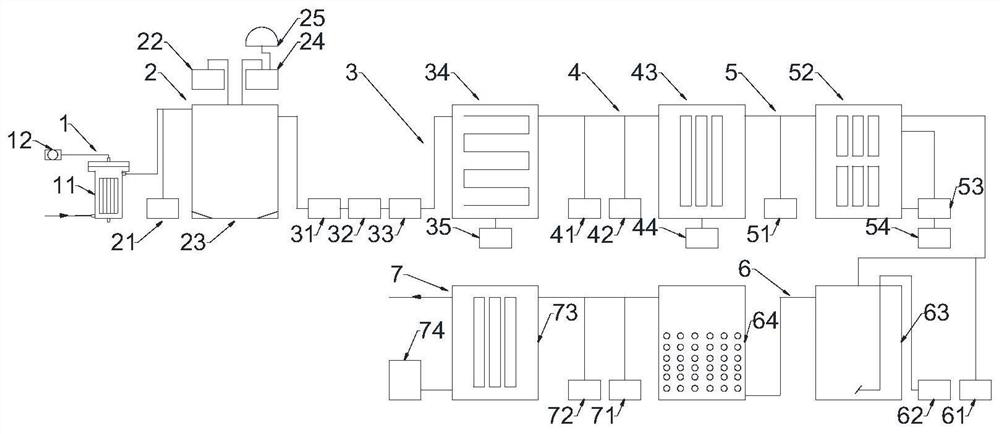

[0055] COD is 47700mg / L, ammonia nitrogen is 926mg / L, total nitrogen is 1442mg / L, total hardness is 2450mg / L, and SS is 20450mg / L, the zero discharge treatment method of landfill leachate is as follows:

[0056] Step 1: Filtration, the landfill leachate flows through the filter, and the fine suspended solids and insoluble impurities in the landfill leachate are removed through the microporous filtration of the filter. After treatment, COD was 45697mg / L, ammonia nitrogen was 913mg / L, total nitrogen was 1358mg / L, total hardness was 2418mg / L, and SS was 15929mg / L.

[0057] Step 2: Anaerobic, the effluent from step 1 enters the anaerobic reactor, and most of the organic pollutants in the leachate are removed through anaerobic biochemical action. The anaerobic biogas is further incinerated through biological desulfurization, and the desulfurization product is sulfur. After treatment, COD is 5219mg / L, ammonia nitrogen is 820mg / L, total nitrogen is 1225mg / L, total hardness is 2388mg...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com