A kind of foam silica ceramic airgel material and preparation method thereof

A silica and aerogel technology, applied in ceramic products, other household appliances, household appliances, etc., can solve the problems of a large number of non-polar solvents, high solvent costs, easy damage to the pore structure, etc., and achieve drying equipment and operation. Low cost, high cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0073] (1) Weigh 3g of surfactant and 12g of water and stir to dissolve for 20 minutes at 25°C to obtain a uniform surfactant solution;

[0074] (2) add the 20-fold diluted ammonia water to adjust the pH of the surfactant solution to 6.35, and stir for 20 minutes to stabilize the pH value; in the surfactant solution, add 6g of TEOS (tetraethoxysilane), stir at 15000rpm for 5 minutes ( High-speed homogenization treatment), then stir at 1000rpm for 50 minutes (low-speed stirring treatment), and let stand at 25°C for two days;

[0075] (3) The solid produced after standing is taken out, soaked and washed with water, and then placed in an oven at 80° C. to dry for 24 hours to obtain aerogel.

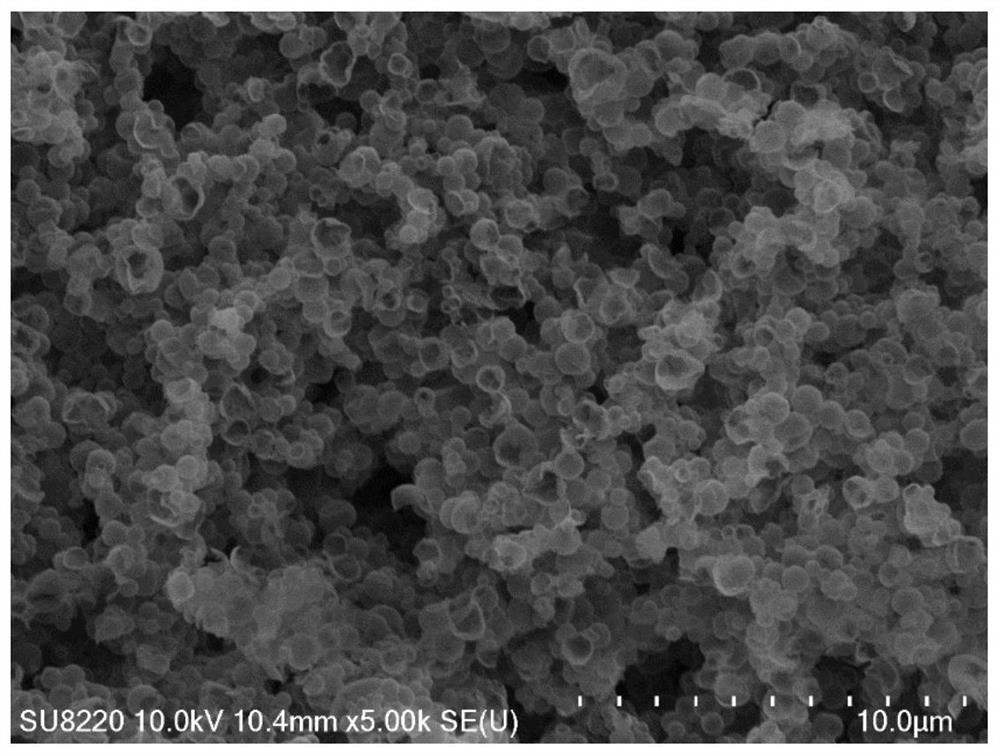

[0076] (4) Burning the obtained aerogel at 500° C. for 2 hours to obtain the foamed silica ceramic aerogel material. The microscopic morphology of the side is as figure 1 . from figure 1 It can be seen that the foam material has a complete foam structure, the size of the foam is about 1 ...

Embodiment 2

[0078] (1) Weigh 3g of surfactant and 9g of water and stir to dissolve for 20 minutes at 25°C to obtain a uniform surfactant solution (surfactant solution);

[0079] (2) add the 20-fold diluted ammonia water to adjust the pH of the surfactant solution to 6.35, and stir for 20 minutes to stabilize the pH value; add 6g of TEOS (tetraethoxysilane) in the surfactant solution, stir at 1000rpm for 50 minutes ( Low-speed stirring treatment), let stand at 25°C for two days;

[0080] (3) Take out the solid produced after standing, soak and wash with a small amount of water, and then place it in an oven at 80° C. to dry for 24 hours to obtain aerogel.

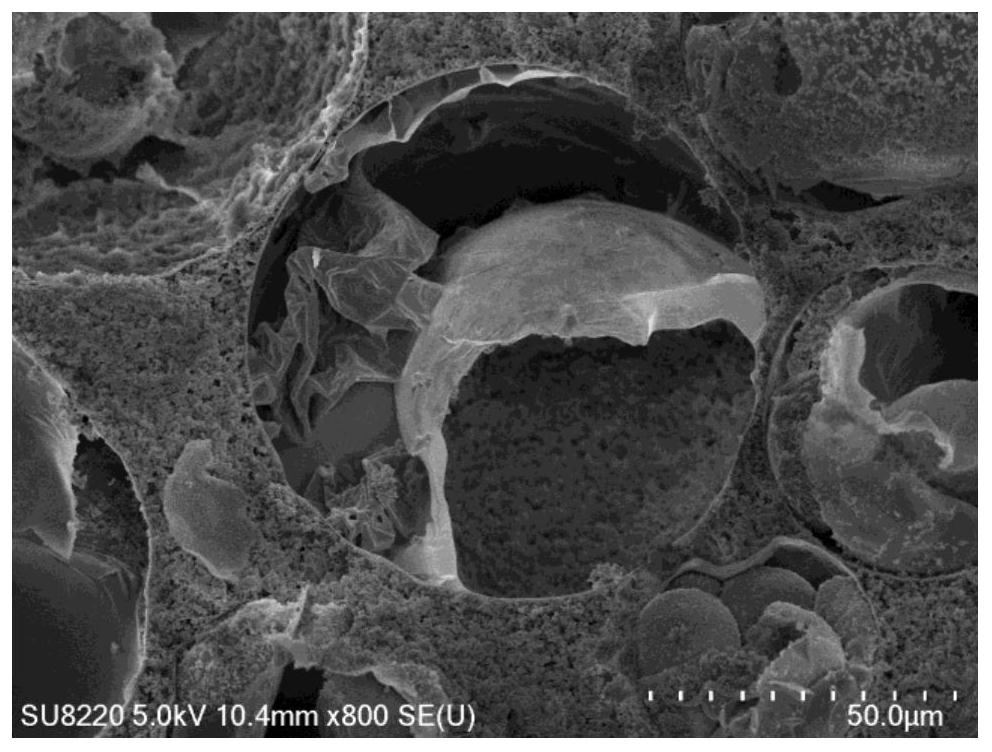

[0081] (4) Burning the obtained aerogel at 500° C. for 2 hours to obtain the foamed silica ceramic aerogel material. The microscopic morphology of the side is as figure 2 . from figure 2 It can be seen that due to the lack of high-speed homogenization treatment in step (2), the pore size becomes larger, and then the density increas...

Embodiment 3

[0083] (1) Weigh 3g of surfactant and 30g of water and stir to dissolve for 20 minutes at 25°C to obtain a uniform surfactant solution (surfactant solution);

[0084] (2) add the 20-fold diluted ammonia water to adjust the pH of the surfactant solution to 6.35, and stir for 20 minutes to stabilize the pH value; in the surfactant solution, add 6g of TEOS (tetraethoxysilane), stir at 15000rpm for 5 minutes ( High-speed homogenization treatment), then stir at 1000rpm for 50 minutes (low-speed stirring treatment), and let stand at 25°C for two days;

[0085] (3) taking out the solid produced after standing, soaking and cleaning with a small amount of water, and then placing it in an oven at 80 ° C and drying for 24 hours to obtain aerogel;

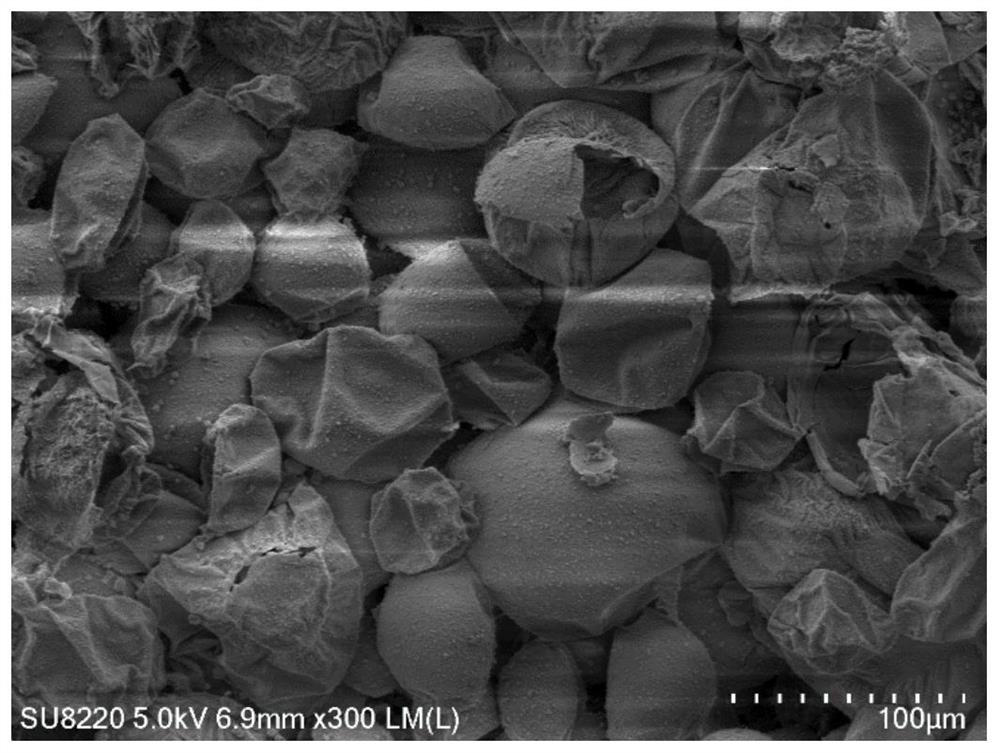

[0086] (4) Burning the obtained aerogel at 500° C. for 2 hours to obtain the foamed silica ceramic aerogel material. Due to the change in the ratio of silicon source and water, its density has changed, as shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com