Method for producing sodium isethionate through continuous reaction

A technology of sodium isethionate and reactor, applied in sulfonate preparation, organic chemistry and other directions, can solve the problems of increasing production cost, increasing the generation of three wastes, prolonging the production process, etc., to optimize the process flow and optimize the process parameters, the effect of reducing the amount of three wastes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

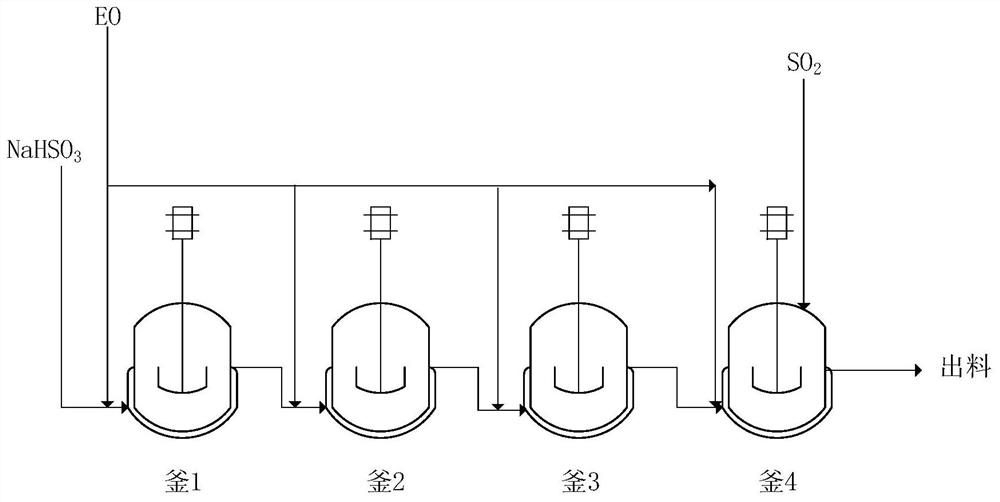

Embodiment 1

[0031] The sodium bisulfite aqueous solution with a mass concentration of 30% enters kettle 1 at a flow rate of 78.78kg / h, and EO is introduced at the same time, the flow rate of EO is linked with the pH in kettle 1, and the pH in the kettle is controlled to be 5.5-6.0, and the flow rate of EO is controlled The range is 7kg / h~8.5kg / h, the temperature of control kettle 1 is 30~35℃, and the volume of material is 195~205L. If the volume exceeds this volume, the material is discharged to kettle 2, and EO is introduced at the same time. The flow rate of EO and the pH in kettle 2 Carry out interlocking, control the pH in the kettle to be 6.0~6.5, the control range of EO flow rate is 0.5kg / h~2kg / h, control the temperature of kettle 2 to be 40~45℃, and the volume of material is 100~105L. Kettle 3, feed EO at the same time, the flow rate of EO is linked with the pH in the kettle 3, the pH in the kettle is controlled to be 6.5-7.0, the flow rate of EO is controlled within the range of 0....

Embodiment 2

[0052] The sodium bisulfite aqueous solution with a mass concentration of 40% enters the kettle 1 at a flow rate of 59.09kg / h, and EO is introduced at the same time. The EO flow rate is linked with the pH in the kettle 1, and the pH in the kettle is controlled to be 5.5-6.0, and the EO flow rate is controlled. The range is 7kg / h~8.5kg / h, the temperature of control kettle 1 is 30~35℃, and the volume of material is 142~147L. If the volume exceeds this volume, the material is discharged to kettle 2, and EO is introduced at the same time. The flow rate of EO and the pH in kettle 2 Carry out interlocking, control the pH in the kettle to be 6.0-6.5, the control range of the EO flow rate is 0.5kg / h-2kg / h, control the temperature of the kettle 2 to be 40-45℃, and the volume of the material to be 70-75L. Kettle 3, feed EO at the same time, the flow rate of EO is linked with the pH in the kettle 3, the pH in the kettle is controlled to be 6.5-7.0, the flow rate of EO is controlled within...

Embodiment 3

[0055] The sodium bisulfite aqueous solution with a mass concentration of 20% enters kettle 1 at a flow rate of 118.18kg / h, and EO is introduced at the same time. The flow rate of EO is linked with the pH in kettle 1, and the pH in the kettle is controlled to be 5.5-6.0, and the flow rate of EO is controlled. The range is 7kg / h~8.5kg / h, the temperature of control kettle 1 is 30~35℃, and the volume of material is 310~315L. If the volume exceeds this volume, the material is discharged to kettle 2, and EO is introduced at the same time. The flow rate of EO and the pH in kettle 2 Carry out interlocking, control the pH in the kettle to be 6.0~6.5, the control range of EO flow rate is 0.5kg / h~2kg / h, control the temperature of kettle 2 to be 40~45℃, and the volume of material is 155~160L. Kettle 3, feed EO at the same time, the flow rate of EO is linked with the pH in the kettle 3, the pH in the kettle is controlled to be 6.5-7.0, the flow rate of EO is controlled within the range of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com