High-purity ultrafine uniform monoclinic zirconium dioxide (ZrO2) nanocrystal material, synthesis method therefor and application of high-purity ultrafine uniform monoclinic ZrO2 nanocrystal material

A zirconium dioxide and nanocrystal technology, applied in the field of ceramic materials, achieves the effects of uniform and controllable particle size, avoiding growth and agglomeration, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

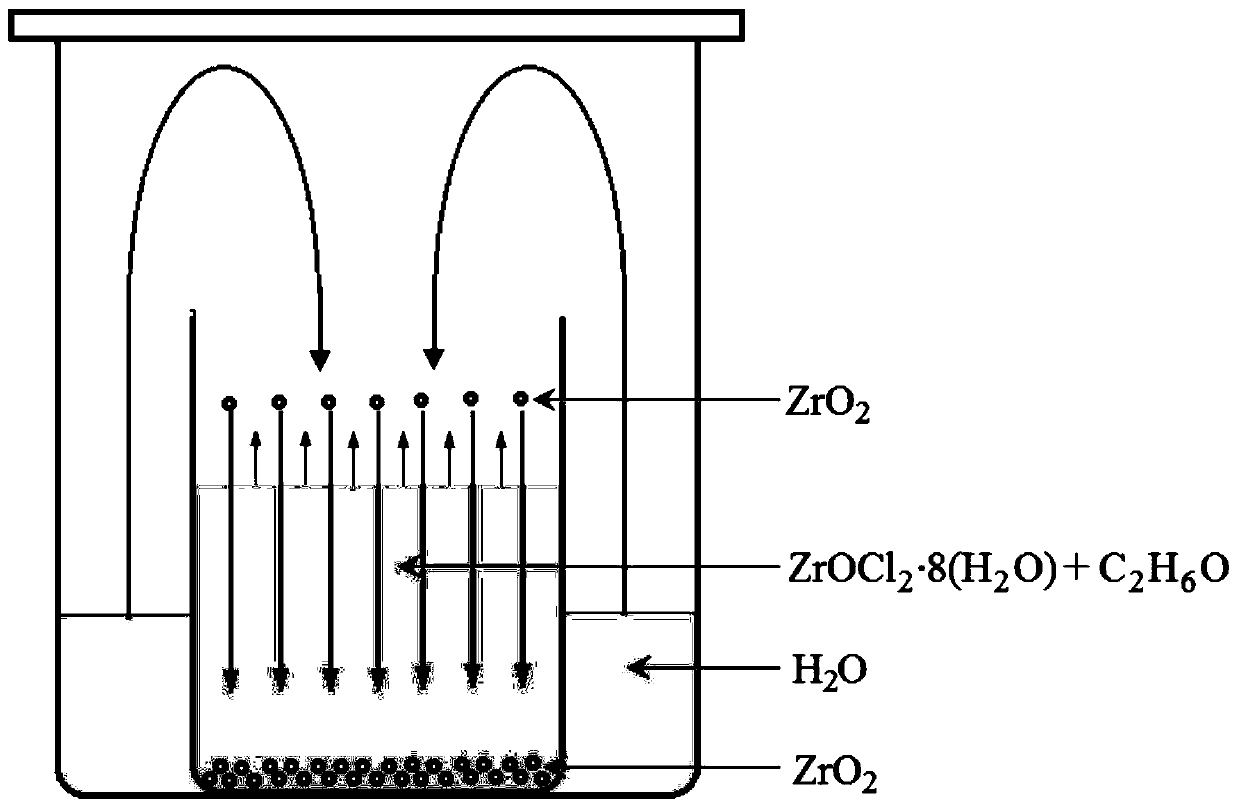

[0024] This embodiment synthesizes high-purity ultrafine uniform monoclinic zirconia (ZrO 2 ) The method of nano crystal material, mainly realizes by following steps:

[0025] (1) Measure 25.0 milliliters of ethanol (Ethanol, C 2 h 6 O) put into a beaker, weigh 2.0 grams of zirconium oxychloride octahydrate (Zirconium Oxychloride Octahydrate, ZrOCl 2 8(H 2 O)) slowly drop into the beaker and mix and stir for 30 minutes;

[0026] (2) Pack the uniformly stirred mixed solution into the polytetrafluoroethylene liner pre-installed with 30mL distilled water, and note that the mixed solution in step (1) does not directly contact with the distilled water;

[0027] (3) Put the polytetrafluoroethylene lining into a stainless steel reaction kettle and seal it, place it in an oven at 180°C for 32 hours, and make water vapor contact with zirconium oxychloride octahydrate under hydrothermal conditions to hydrolyze (see figure 1 );

[0028] (4) After the reaction is finished, the react...

Embodiment 2

[0031] This embodiment synthesizes high-purity ultrafine uniform monoclinic zirconia (ZrO 2 ) The method of nano crystal material, mainly realizes by following steps:

[0032] (1) Measure 25.0 milliliters of ethanol (Ethanol, C 2 h 6 O) put into a beaker, weigh 2.0 grams of zirconium oxychloride octahydrate (Zirconium Oxychloride Octahydrate, ZrOCl 2 8(H 2 O)) slowly drop into the beaker and mix and stir for 20 minutes;

[0033] (2) Pack the uniformly stirred mixed solution into the polytetrafluoroethylene liner pre-installed with 30mL distilled water, and pay attention to the mixed solution in step (1) not in direct contact with the distilled water;

[0034] (3) Put the polytetrafluoroethylene liner into a stainless steel reaction kettle and seal it, place it in an oven at 150° C. for 48 hours, and make water vapor contact with zirconium oxychloride octahydrate to undergo hydrolysis under hydrothermal conditions;

[0035] (4) After the reaction is finished, the reactor i...

Embodiment 3

[0038] This embodiment synthesizes high-purity ultrafine uniform monoclinic zirconia (ZrO 2 ) The method of nano crystal material, mainly realizes by following steps:

[0039] (1) Measure 25.0 milliliters of ethanol (Ethanol, C 2 h 6 O) put into a beaker, weigh 2.0 grams of zirconium oxychloride octahydrate (Zirconium Oxychloride Octahydrate, ZrOCl 2 8(H 2 O)) slowly drop into the beaker and mix and stir for 10 minutes;

[0040] (2) Pack the uniformly stirred mixed solution into the polytetrafluoroethylene liner pre-installed with 30mL distilled water, and note that the mixed solution in step (1) does not directly contact with the distilled water;

[0041] (3) Put the polytetrafluoroethylene liner into a stainless steel reaction kettle and seal it, place it in an oven at 200°C for 24 hours, and make the water vapor contact with zirconium oxychloride octahydrate to undergo hydrolysis under hydrothermal conditions;

[0042] (4) After the reaction is finished, the reactor is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com