Polymerizable double onium salt structure-containing photoacid generator, preparation method and photoresist

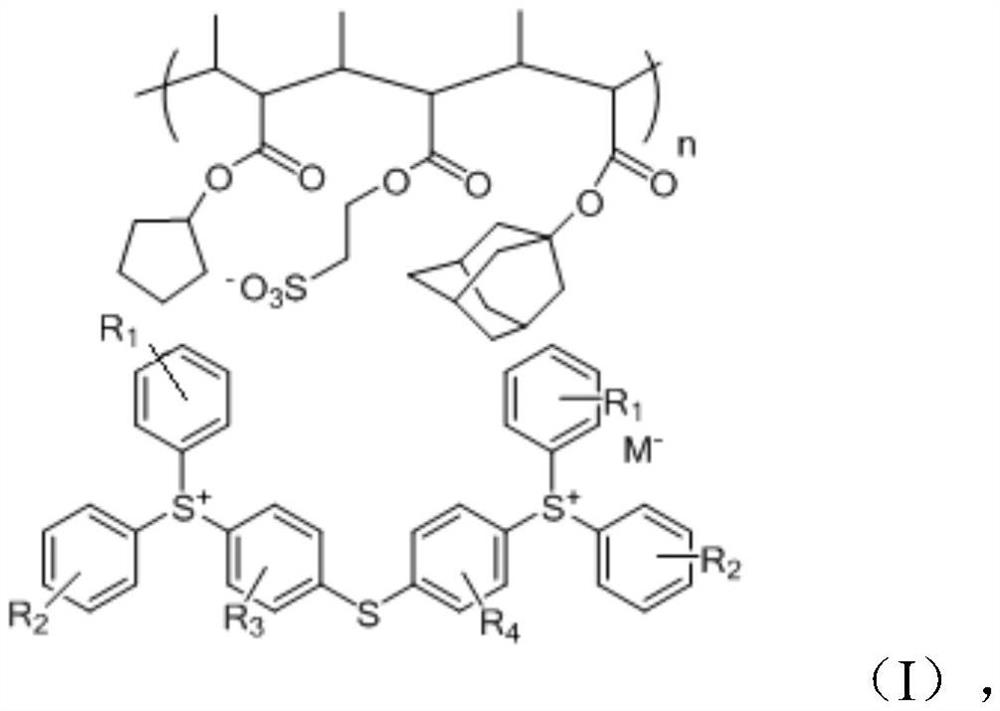

A photoacid generator, polymerized technology, applied in the field of photoresist, can solve the problems of limited absorption wavelength and low acid generation efficiency of photoacid generator, achieve uniform distribution, improve line width and roughness, and achieve high yield. The effect of acid efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

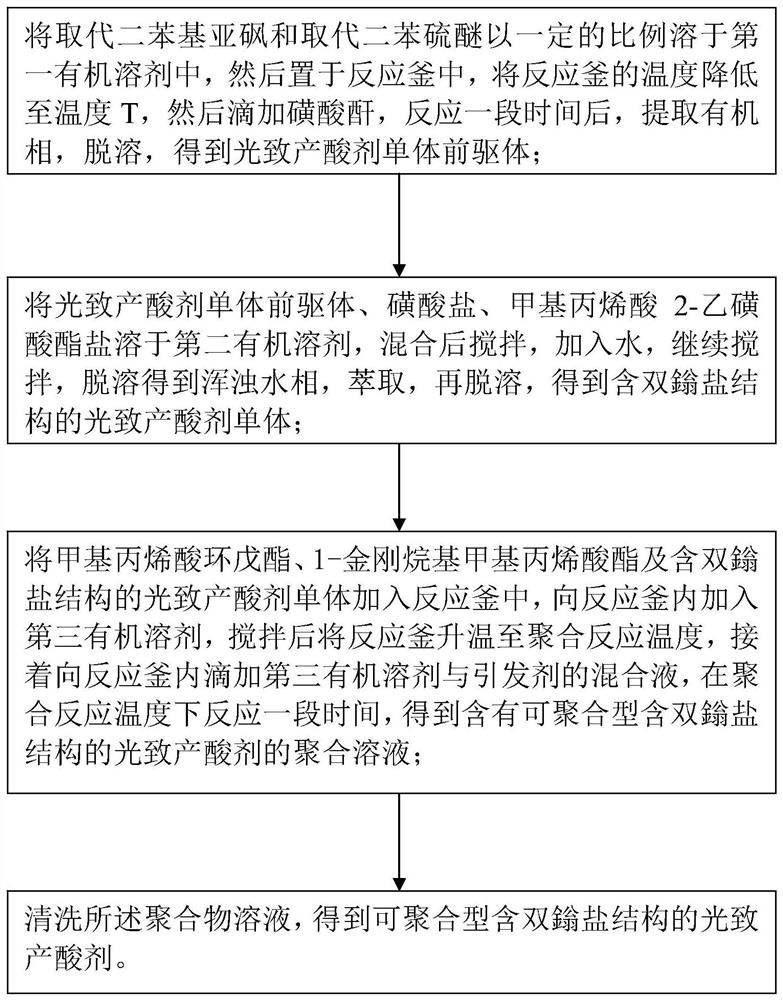

[0034] see figure 1 , The preparation method of the polymerizable photoacid generator containing bis-onium salt structure according to one embodiment of the present invention comprises the following steps:

[0035] Step S1: preparing a photoacid generator monomer containing a bis-onium salt structure, including the following steps:

[0036] a 1 1. Dissolve the substituted diphenyl sulfoxide and substituted diphenyl sulfide in the first organic solvent in a certain proportion, then place them in a reaction kettle filled with nitrogen, reduce the temperature of the reaction kettle to temperature T, and then add sulfuric acid dropwise Anhydride, react for a period of time t 1 , add water, stop the reaction, then cool the temperature of the reaction kettle to room temperature, extract the organic phase by liquid separation, precipitation to constant weight, and wash the organic phase to obtain compound A, which is the monomer precursor of the photoacid generator. The chemical re...

Embodiment 1

[0077] Preparation of Photoacid Generator Monomer Containing Bisium Salt Structure

[0078] a 1 1. Dissolve 21g of diphenyl sulfoxide and 19g of diphenyl sulfide in 300ml of dichloromethane, then place it in a reactor filled with nitrogen, lower the temperature of the reactor to -15°C, and then add 29g of trifluoromethane dropwise Sulfonic anhydride, dropwise for 3 minutes, react for 3 hours, add 200ml of pure water, stop the reaction, then cool the temperature of the reactor to room temperature, extract the organic phase by liquid separation, precipitate to constant weight, wash twice with 50ml of ether , to obtain 22g compound A, the chemical reaction formula is as follows:

[0079]

[0080] a 2 , Dissolve 86g of compound A, 33g of sodium perfluorobutylsulfonate, 20g of 2-ethanesulfonate sodium methacrylate in 50g of methanol (MeOH), mix and stir for 12 hours, add 50ml of pure water, and continue stirring for 3 hours , precipitation to obtain a turbid water phase, use ...

Embodiment 2

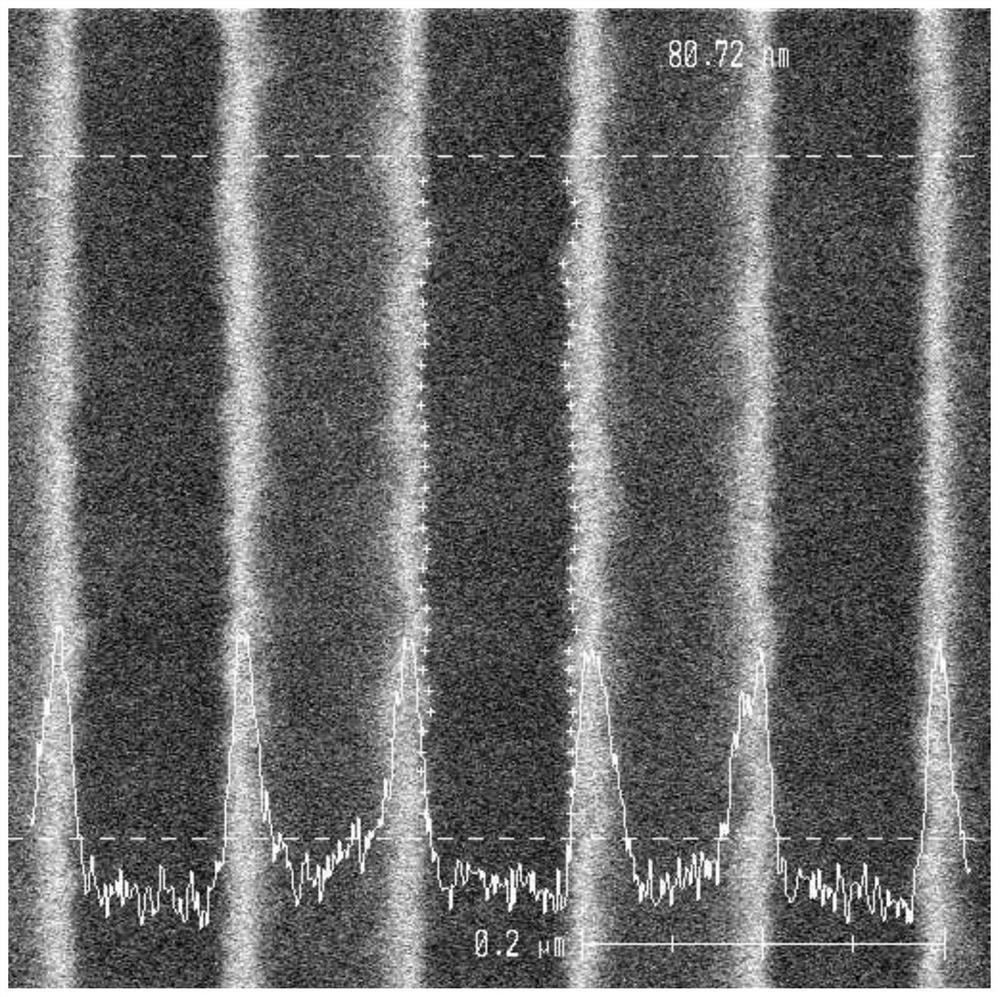

[0092] Preparation of photoresist

[0093] In a clean 100mL glass bottle, add 8.5g of a polymerizable photoacid generator containing a bisium salt structure, 0.06g of a mixed acid with a mass ratio of tert-butylamine and diisobutylamine of 2:8 Diffusion inhibitor, 32g propylene glycol methyl ether acetate, 48g propylene glycol monomethyl ether to obtain a mixture, the mixture was shaken in a bottle in the dark for 24 hours to fully dissolve to obtain a mixed solution. Then, filter the mixed solution successively with 0.22 micron and 0.02 micron nylon and UPE filters, collect the filtrate, and obtain photoresist.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com