Photoacid generator containing double onium salt structure, preparation method and photoresist composition

A technology of photoacid generator and onium salt, which is applied in the field of photoresist, can solve the problem of low acid production efficiency and achieve high acid production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

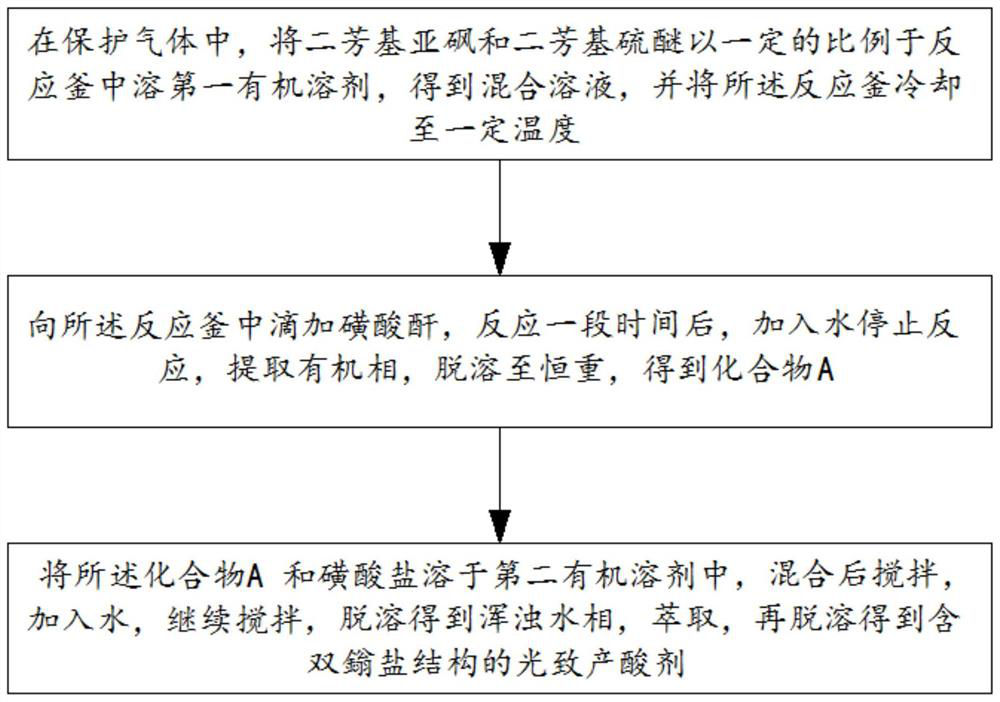

[0035] In the second aspect, for the above-mentioned photoacid generator, the present invention also provides a preparation method of the photoacid generator. It includes the following steps:

[0036] S11: In a protective gas, diaryl sulfoxide and diaryl sulfide are dissolved in a first organic solvent in a certain ratio in a reactor to obtain a mixed solution, and the reactor is cooled to a certain temperature.

[0037] Wherein the range of the cooling temperature is -30-30°C.

[0038] In a specific embodiment of the present invention, the diaryl sulfoxide is diphenyl sulfoxide, the diaryl sulfide is diphenyl sulfide, and the first organic solvent includes but not limited to dichloromethane, chloroform And one or more of dichloroethane. Diphenyl sulfoxide and diphenyl sulfide were dissolved in dichloromethane in a nitrogen atmosphere, and the temperature was cooled to -30-30°C.

[0039] S12: Add sulfonic anhydride dropwise into the reaction kettle, after a period of reacti...

Embodiment 1

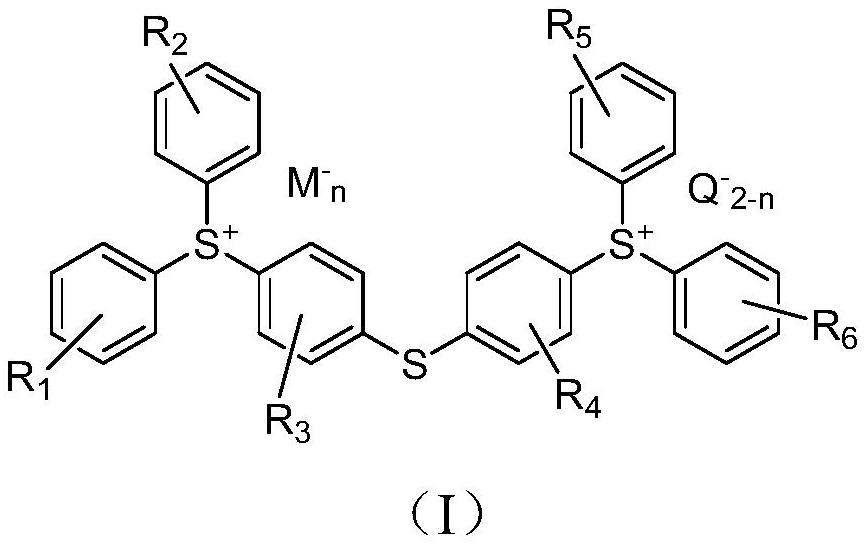

[0082] Example 1: Preparation of a photoacid generator containing a bis-onium salt structure

[0083] S11: Dissolve 21g of diphenyl sulfoxide and 19g of diphenyl sulfide in 300ml of dichloromethane, put them into a reactor filled with nitrogen, and lower the temperature of the reactor to -15°C

[0084] S12, add 29 g of trifluoromethanesulfonic anhydride dropwise to the above-mentioned reaction kettle, and the dropping time is 30 minutes, react for 3 hours, add 200ml of pure water to stop the reaction, cool the temperature of the reaction kettle to room temperature, separate the liquid to take the organic phase, remove Dissolved to constant weight, washed twice with 50ml of diethyl ether to obtain 22g of compound A.

[0085] Its reaction formula is as follows:

[0086]

[0087] S13, 86g of compound A was dissolved in 50g of methanol, 33g of sodium perfluorobutanesulfonate was dissolved in 50g of methanol, 20g of sodium p-toluenesulfonate was dissolved in 50g of methanol, st...

Embodiment 2

[0091] Embodiment two: prepare film-forming resin

[0092] S21, add 45g of monomer 1, 50g of monomer 2, and 20g of monomer 3 into a reactor filled with nitrogen, add 60g of ethyl acetate into the reactor, stir evenly to obtain a mixture of monomers, and then heat up the reactor to At 77°C, mix 10g of ethyl acetate and 12g of benzoyl peroxide to obtain a mixed liquid of the initiator, drop the mixed liquid of the initiator into the reactor of the mixed liquid of the monomer, and react at 77°C for 7 hours , stop the reaction, and the reactor temperature is cooled to room temperature.

[0093] S22, add 600g of methanol into the reaction kettle lowered to room temperature, and after 1 hour of producing the first precipitate, drain the liquid in the reaction kettle, and then add 70g of ethyl acetate into the reaction kettle until the first precipitate dissolves.

[0094] S23, add 600g of methanol into the reaction kettle, after the second precipitate is generated, export the liqui...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com