Preparation method of fermented jackfruit vinegar

The technology of pineapple fruit and jackfruit is applied in the field of preparation of fermented jackfruit fruit vinegar, which can solve the problems that the nutritional value of jackfruit is not fully utilized, the flavor of jackfruit fruit vinegar is not outstanding, and the acetic acid fermentation is insufficient, etc., so as to improve the lipid metabolism of human body , retain nutrition and unique taste, rich in acidity and aroma components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

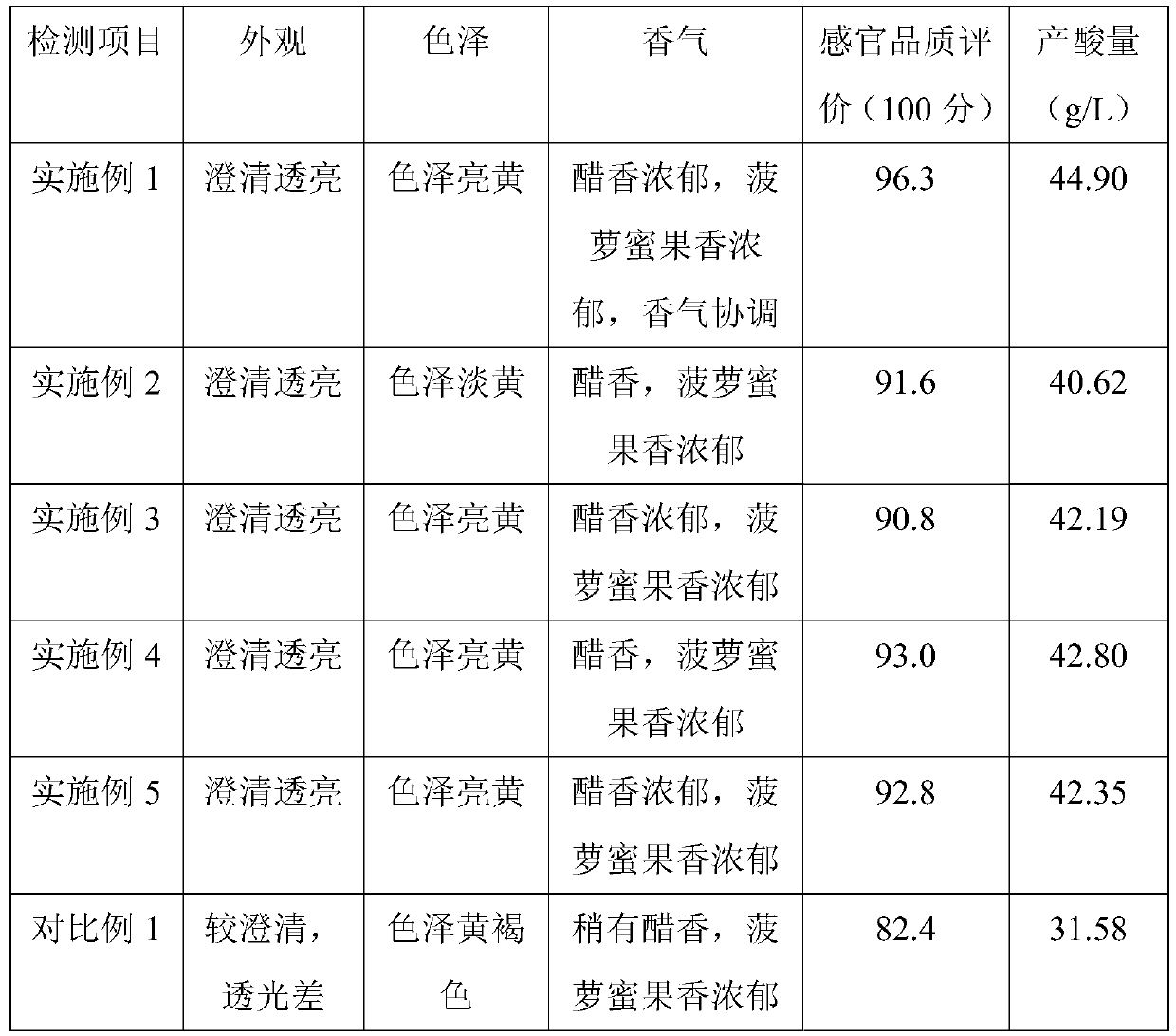

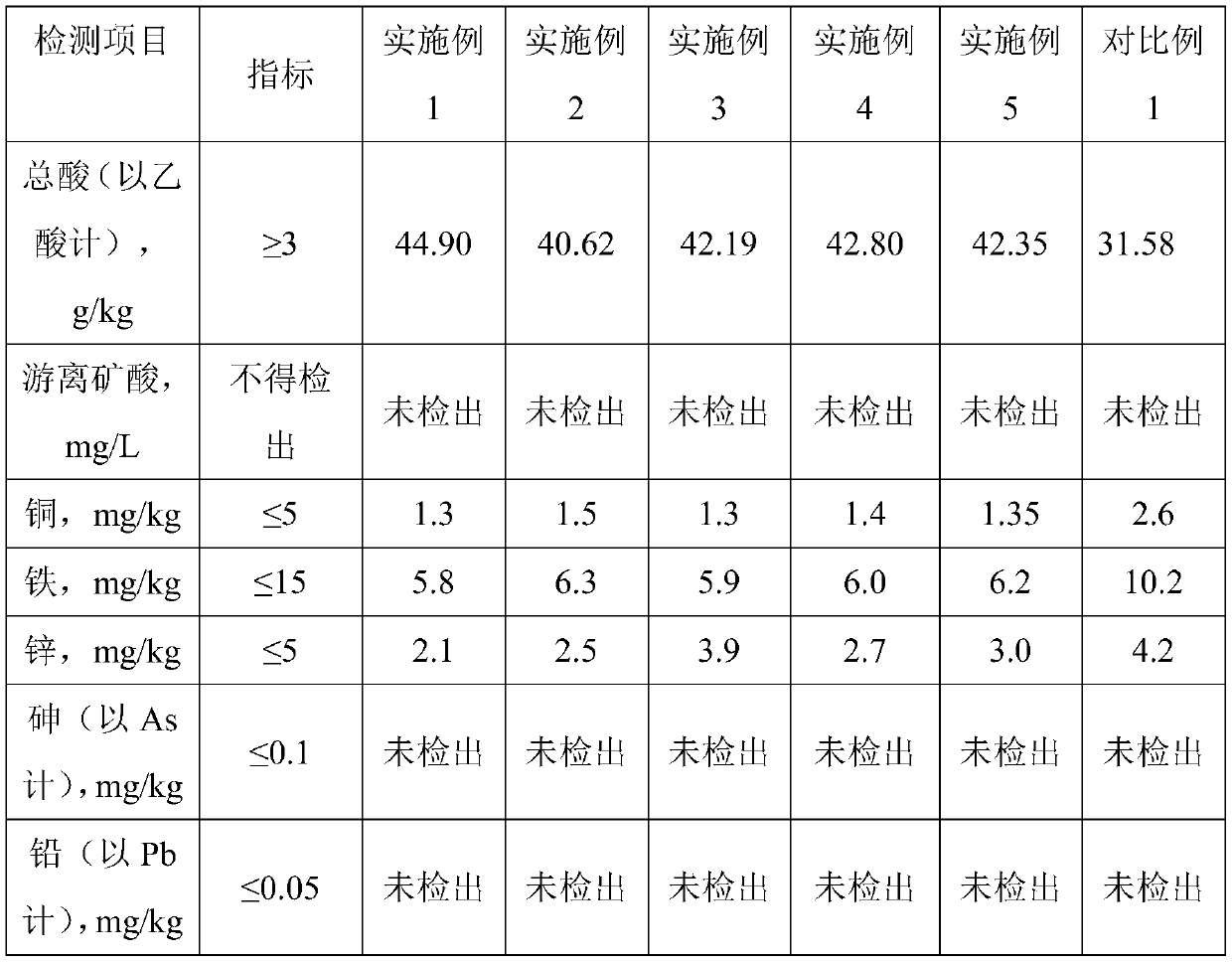

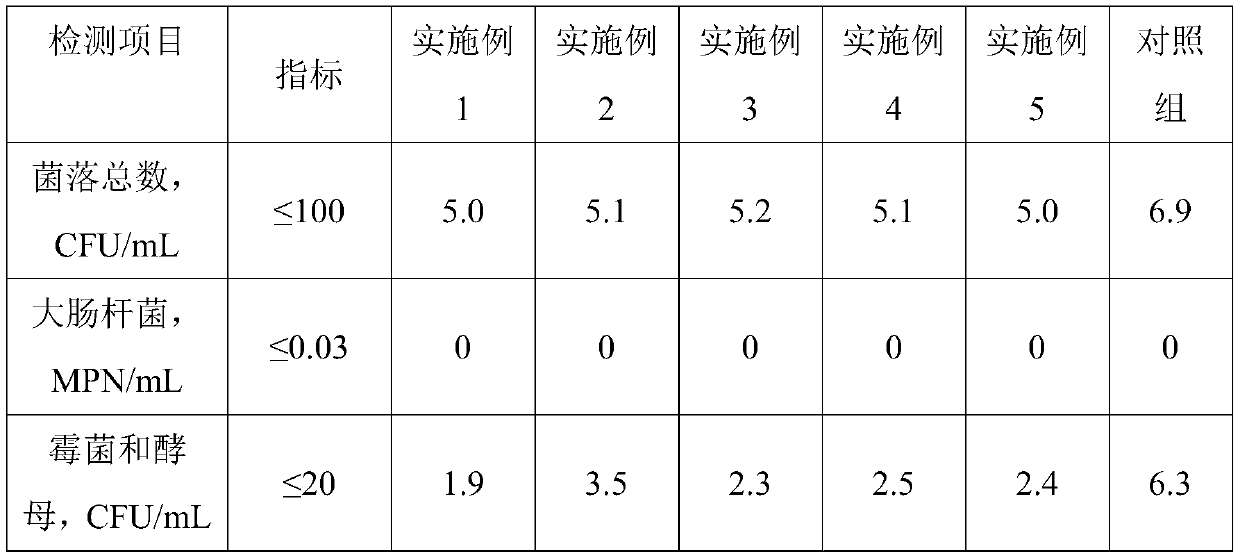

Examples

Embodiment 1

[0093] The preparation of embodiment 1 fermented jackfruit fruit vinegar

[0094] A preparation method for fermented pineapple fruit vinegar, comprising the following steps:

[0095] S1. Select the jackfruit that is nine-ripe, free from diseases and insect pests and has a complete shape as a spare raw material, peel, remove the core, get the pulp, and after cleaning, obtain the jackfruit pulp, put into color-protecting agent (0.1g / L ascorbic acid, 8g / L lemon After soaking in acid) for 20 minutes, mix the soaked jackfruit pulp with distilled water according to the mass volume ratio of 1:1.5, and homogenate to obtain jackfruit pulp;

[0096] S2. Add 0.1g / L sodium metabisulfite to the jackfruit pulp obtained in step S1 to inhibit bacteria, and use 0.5g / L pectinase to enzymolyze it for 3h at 30°C, adjust the sugar content to 240g / L, and the pH to be 5.5, obtain jackfruit fermented liquid;

[0097] S3. Adding 7% saccharomyces secondary expansion seed solution to the jackfruit fer...

Embodiment 2

[0099] The preparation of embodiment 2 fermented jackfruit fruit vinegar

[0100] A preparation method for fermented pineapple fruit vinegar, comprising the following steps:

[0101] S1. select the jackfruit that is nine-ripe, free from diseases and insect pests and has a complete shape as a spare raw material, after peeling, removing the core, getting the pulp, and cleaning, the jackfruit pulp is obtained, and the color-protecting agent (0.05g / L ascorbic acid, 6g / L lemon After soaking in acid) for 10 minutes, the soaked jackfruit pulp and distilled water were mixed according to the mass volume ratio of 1:0.5, and homogenized to obtain jackfruit pulp;

[0102] S2. Add 0.05g / L sodium metabisulfite to the jackfruit pulp obtained in step S1 to inhibit bacteria, and use 0.25g / L pectinase to enzymolyze it for 1h at 28°C, adjust the sugar content to 220g / L, and the pH to be 4.5, obtain jackfruit fermented liquid;

[0103] S3. Add 5% saccharomyces to the jackfruit fermented liquid ...

Embodiment 3

[0105] The preparation of embodiment 3 fermented jackfruit fruit vinegar

[0106] A preparation method for fermented pineapple fruit vinegar, comprising the following steps:

[0107] S1. select the jackfruit that is nine-ripe, free from diseases and insect pests and has a complete shape as a spare raw material, after peeling, removing the core, getting the pulp, and cleaning, to obtain the jackfruit pulp, put into color-protecting agent (0.15g / L ascorbic acid, 10g / L lemon After soaking in acid) for 30 minutes, mix the soaked jackfruit pulp with distilled water according to the mass volume ratio of 1:2.5, and homogenate to obtain jackfruit pulp;

[0108] S2. Add 0.15g / L sodium metabisulfite to the jackfruit pulp obtained in step S1 to inhibit bacteria, and use 0.75g / L pectinase to enzymolyze it for 3h at 30°C, adjust the sugar content to 260g / L, and the pH to be 6.5, obtaining the jackfruit fermented liquid;

[0109] S3. Add 9% saccharomyces secondary expansion seed liquid to...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com