Modified engineering plastic for manufacturing 5G communication filter and preparation method thereof

A technology for engineering plastics and filters, applied in the field of engineering plastics, can solve the problems of reports, no plastic materials, etc., and achieve the effects of high thermal deformation temperature, small deformation at high temperature, and stable dielectric constant.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0053] The present invention provides the preparation method of the modified engineering plastics for making 5G communication filter, comprising the following steps:

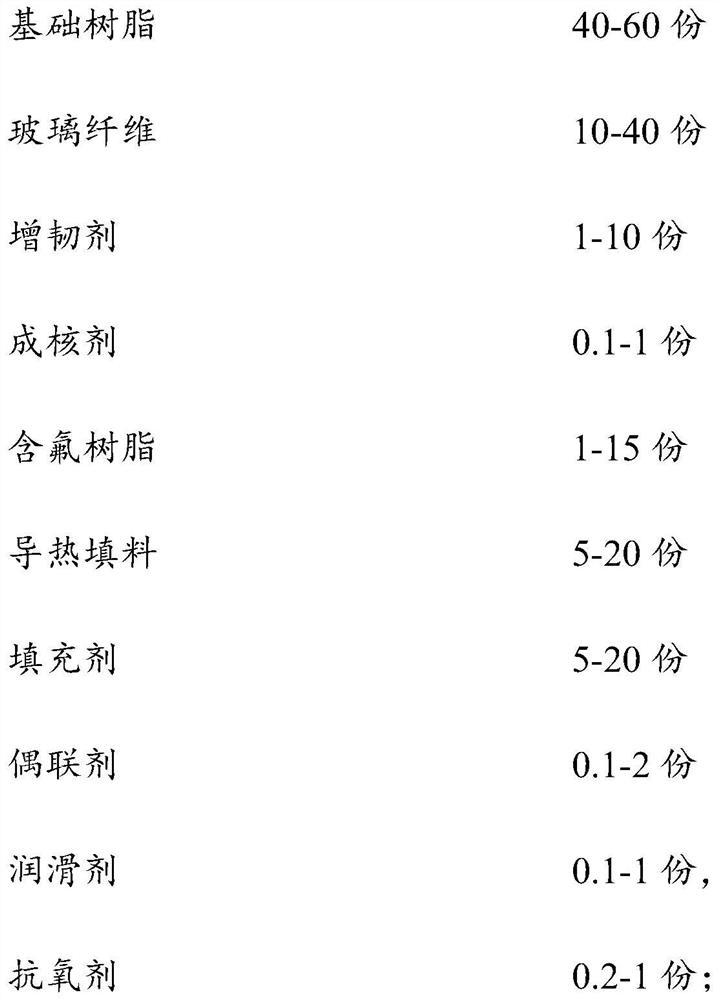

[0054] Weigh 40-60 parts of base resin, 1-10 parts of toughening agent, 0.1-1 part of nucleating agent, 1-15 parts of fluorine-containing resin, 5-20 parts of thermal conductive filler, 5-20 parts of filler, coupling agent After 0.1-2 parts, 0.1-1 part of lubricant and 0.2-1 part of antioxidant, mix evenly to obtain a compound; add the compound to the main feed of the twin-screw extruder, add 10-40 parts of glass fiber In the side feeding of the twin-screw extruder, after melt extrusion, it is drawn out from the outlet of the die head, and after water cooling, it is pelletized to obtain the modified engineering plastic particles for making 5G communication filters.

[0055] Further, the melting extrusion temperature of the twin-screw extruder is 300-350° C., and the screw speed is 150-450 rpm / min.

Embodiment 1

[0059] This embodiment provides a modified engineering plastic for making a 5G communication filter, the modified engineering plastic is composed of the following components by weight:

[0060]

[0061] The preparation method of the modified engineering plastics is:

[0062] Weigh 40 parts of polyphenylene sulfide, 1 part of ethylene-acrylate-MAH copolymer, 0.1 part of sodium ion-type EAA copolymer, 7 parts of PVDF, 5 parts of graphene, 5 parts of hollow glass microspheres, KH5600 according to parts by weight .5 parts, 1 part of PETS, 0.2 parts of antioxidant 1010, 0.2 parts of antioxidant 168, mix evenly to obtain a mixture, add the mixture into the main feed of the twin-screw extruder, and add special-shaped E glass fiber / round Add 30 parts of ordinary glass fiber into the side feed of the twin-screw extruder, melt it and extrude it from the outlet of the die head, water-cool it and cut it into pellets to obtain modified engineering plastic particles for making 5G communi...

Embodiment 2

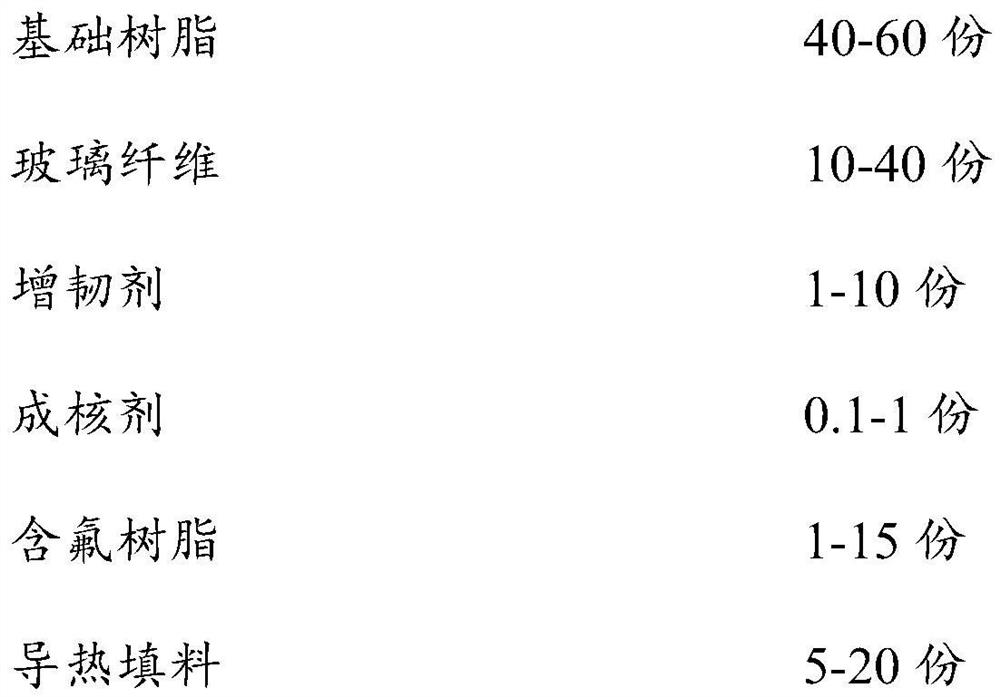

[0065] This embodiment provides a modified engineering plastic for making a 5G communication filter, the modified engineering plastic is composed of the following components by weight:

[0066]

[0067] The preparation method of the modified engineering plastics is:

[0068] Weigh 50 parts of polyphenylene sulfide, 5 parts of ethylene-acrylate-GMA copolymer, 0.7 part of calcium ion type EAA copolymer, 1 part of PTFE, 20 parts of aluminum nitride / carbon nanotube, and hollow glass microtube according to parts by weight. After 10 parts of beads / mica, 2 parts of KH550, 0.8 parts of PETS, 0.3 parts of antioxidant 1076, and 0.2 parts of antioxidant 168, mix them evenly to obtain a mixture, and add the mixture to the main feed of the twin-screw extruder , add 10 parts of special-shaped E glass fiber into the side feed of the twin-screw extruder, and lead it out from the outlet of the die after melt extrusion, water-cooled and pelletized to obtain modified engineering plastic parti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| heat deflection temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com