Production method of glucosamine

A technology of glucosamine and production method, which is applied in the field of glucosamine production, can solve the problems of low glucosamine yield and conversion rate, and achieve the effect of meeting the growth requirements of bacteria and high yield and conversion rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

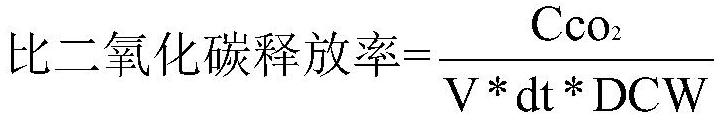

Method used

Image

Examples

Embodiment 1

[0061] Embodiment 1: 100L tank fermentation production process

[0062] (1) Seed activation

[0063] Draw a little bacterial solution from the seed preservation tube for gradient dilution, draw a little bacterial suspension onto the plate medium, and cultivate at 32°C for 24 hours to obtain a mature single colony. The plate medium components are as follows: sodium chloride 5g / L, peptone 10g / L, yeast extract powder 10g / L, agar powder 20g / L, adjust its pH value to 7.5 before sterilization, and then in 121 ℃ Sterilize for 25 minutes.

[0064] (2) shake flask culture

[0065]Pick 3 single colonies from the mature plate culture medium into a shake flask filled with 100mL shake flask culture medium. The shake flask is a 1L Erlenmeyer flask and cultured on a shaker at a culture temperature of 32°C and a rotation speed of 220rpm for 20h When the wet weight of the thalline reaches 8g / L, it can be moved to the seed tank for cultivation. The shake flask medium components are as follo...

Embodiment 2

[0077] Example 2: 5m 3 Tank fermentation production process

[0078] (1)-(3) are the same as embodiment 1;

[0079] (4) Fermentation culture

[0080] Prepare the fermentation medium and sterilize it at 121°C for 25 minutes, adjust its pH value to 7.2 before sterilization, and move the seed liquid of the seed tank to 5m according to the inoculation amount of 15%. 3 Fermentation tank, liquid volume is 2.5m 3 . Initial culture conditions: culture temperature 32°C, rotation speed 150rpm, aeration ratio 0.5VVM, tank pressure 0.03MPa, the pH value is controlled at around 7.2 by supplementing ammonia water during the fermentation culture process, and the feeding concentration during the fermentation culture process is 55% glucose solution and 0.4% sulfuric acid Ammonium is used to control the content of carbon source and nitrogen source at 0.5g / L and 1.1g / L respectively.

[0081] The fermentation medium components are glucose 10g / L, sodium dihydrogen phosphate 10g / L, magnesium c...

Embodiment 1-1

[0091] Example 1-1: 5m 3 Tank fermentation production process

[0092] (1)-(3) are the same as embodiment 1;

[0093] (4) Fermentation culture

[0094] Prepare the fermentation medium and sterilize it at 121°C for 25 minutes, adjust its pH value to 7.2 before sterilization, and move the seed liquid of the seed tank to 5m according to the inoculation amount of 15%. 3 Fermentation tank, liquid volume is 2.5m 3 . Initial culture conditions: culture temperature 32°C, rotation speed 150rpm, aeration ratio 0.5VVM, tank pressure 0.03MPa, the pH value is controlled at around 7.2 by supplementing ammonia water during the fermentation culture process, and the feeding concentration during the fermentation culture process is 55% glucose solution and 0.4% sulfuric acid Ammonium is used to control the content of carbon source and nitrogen source at 0.5g / L and 1.1g / L respectively.

[0095] The fermentation medium components are glucose 10g / L, sodium dihydrogen phosphate 10g / L, magnesium...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com