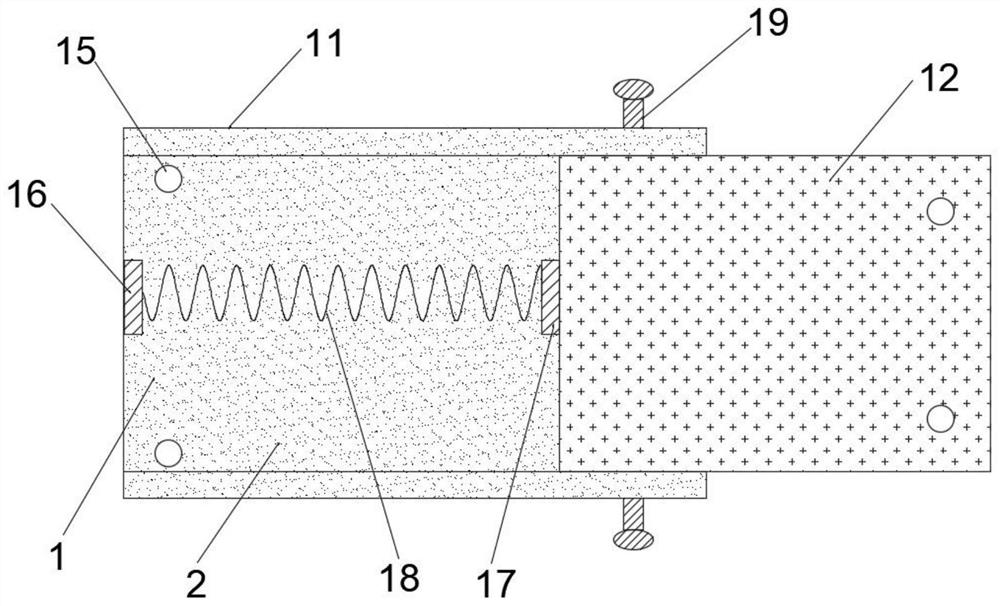

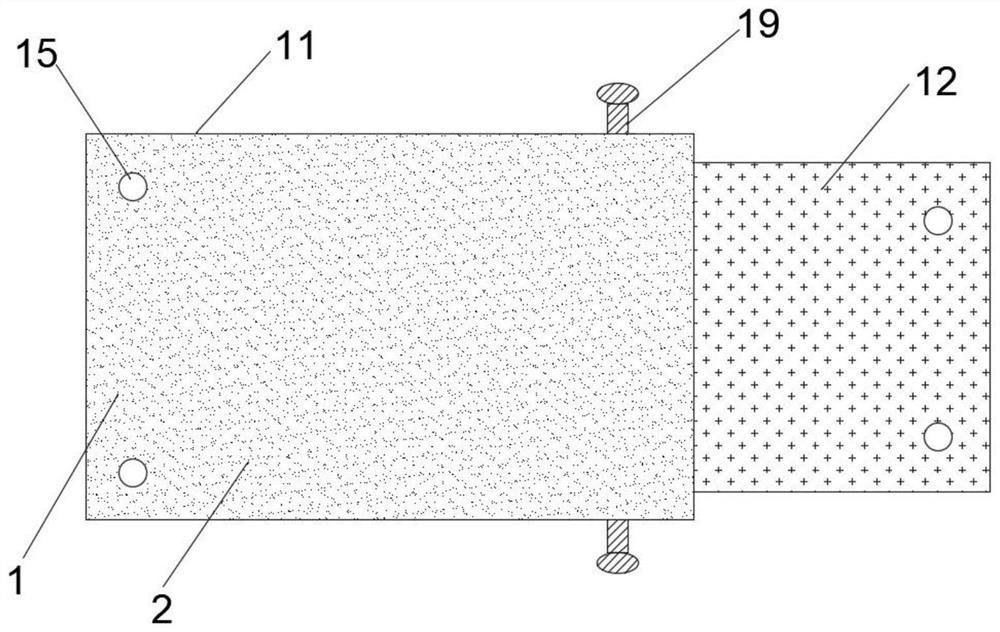

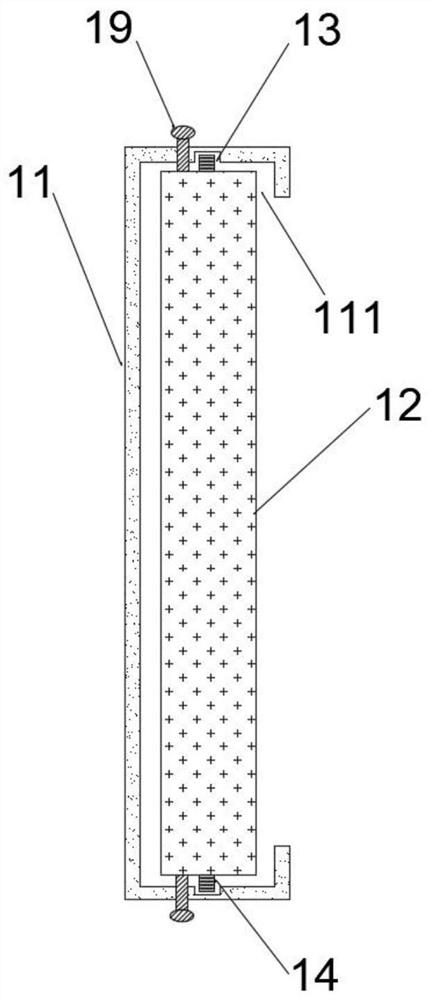

Telescopic connecting piece for plate-type solid wood furniture

A telescopic and connecting piece technology, which is applied in the direction of furniture connection, connecting components, thin plate connection, etc., can solve the problems of shortening the service life of solid wood furniture, joints that cannot be freely stretched, splitting and damage of solid wood boards, etc., and achieves excellent anti-rust effect , Restoring sealing and preventing corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Aluminum zinc phosphate nanoparticles are prepared by the following steps:

[0035]Step A1: Weigh 0.8mmol of zinc oxide and 0.5mmol of aluminum hydroxide into the reactor, add 200mL of deionized water, shake and stir in an ultrasonic oscillator for 0.5 hours, add 50mL of phosphoric acid, and heat and stir for 1 hour to obtain aluminum phosphate Zinc, wherein the heating temperature is 70°C, and the stirring speed is 200rpm;

[0036] In step A2, 120 mg of aluminum zinc phosphate prepared in step A1 was filtered under reduced pressure, and the filter cake was washed with 40 mL of absolute ethanol, and then dried to obtain aluminum zinc phosphate nanoparticles, wherein the drying temperature was 50°C .

Embodiment 2

[0038] Embodiment 2 is a retractable connector for panelized solid wood furniture coated with a nano-aluminum-zinc phosphate anti-rust coating 2, wherein the nano-aluminum-zinc phosphate anti-rust coating 2 is prepared by the following steps:

[0039] Step S1: weighing 10 parts of aluminum-zinc phosphate nanoparticles, 18 parts of epoxy resin, 4 parts of thickener, 1 part of dispersant, and 4 parts of film-forming aid in parts by weight;

[0040] Step S2: Add epoxy resin to the reaction kettle, add aluminum zinc phosphate nanoparticles, thickener, and dispersant, perform sufficient mechanical stirring after heating, and then add deionized water to adjust to a suitable viscosity to obtain an intermediate. Wherein the consumption of deionized water is to add 8 parts of deionized water in every part of aluminum-zinc phosphate nanoparticles, and the thickener is made of hydroxymethyl hydroxyethyl cellulose and hydroxypropyl cellulose with a mass ratio of 1:2. Mixed thickener, disp...

Embodiment 3

[0043] Embodiment 3 is a retractable connector for panelized solid wood furniture coated with a nano-aluminum-zinc phosphate anti-rust coating 2, wherein the nano-aluminum-zinc phosphate anti-rust coating 2 is prepared by the following steps:

[0044] Step S1: weighing 11 parts of aluminum-zinc phosphate nanoparticles, 19 parts of epoxy resin, 5 parts of thickener, 2 parts of dispersant, and 5 parts of film-forming aid in parts by weight;

[0045] Step S2: Add epoxy resin to the reaction kettle, add aluminum zinc phosphate nanoparticles, thickener, and dispersant, perform sufficient mechanical stirring after heating, and then add deionized water to adjust to a suitable viscosity to obtain an intermediate. Wherein the amount of deionized water is 9 parts of deionized water added to each part of aluminum zinc phosphate nanoparticles, the thickener is a copolymer emulsion thickener of acrylic acid and methacrylic acid, and the dispersant is glyceryl tristearate and hydrocarbon Pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com