Preparation method of space gallium arsenide solar cell electrode combined with germanium

A solar cell, gallium arsenide technology, applied in circuits, photovoltaic power generation, electrical components, etc., can solve the problems of expensive single cells, low product reliability, corroded cells, etc., to improve material utilization and reduce process costs. , the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

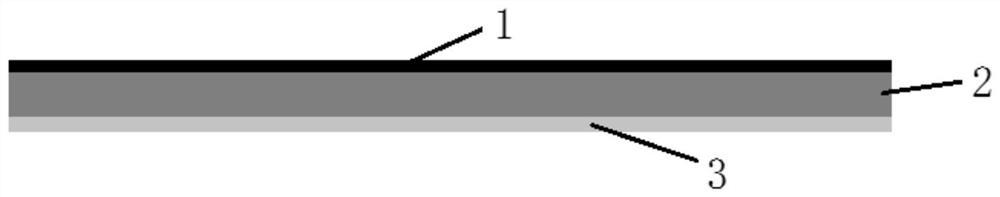

Method used

Image

Examples

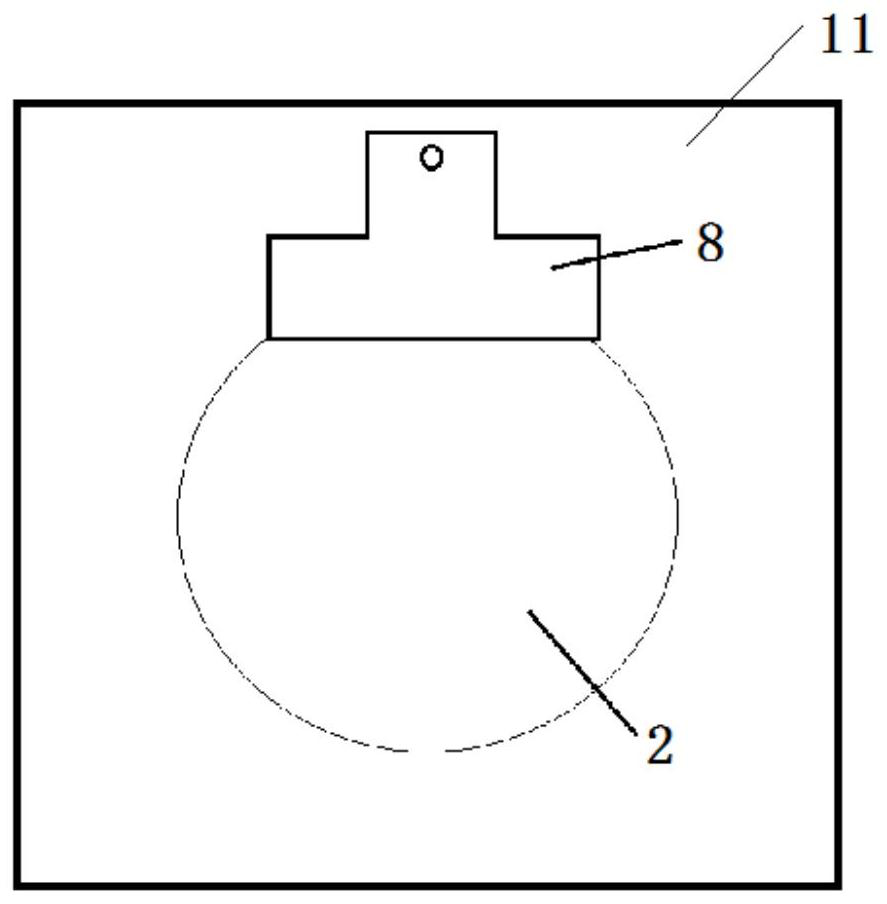

Embodiment 1

[0031]S1: Corrosion EtOAc EtOAc EtOAc EtOAc EtOAc EtOAc Solids Soak 55 ~ 65S; after soaking, the epithelial sheet was taken out in the deionized water, and the repeated flushing multiple times, preferably 10-15 times; placed the epithelial sheet in HF: HNO3: H2The O volume ratio of 2: 1: 10 is soaked in the mixed acid solution of 2: 1: 10, so as soon as soaking the epitaxial sheet, the delay is taken out of the deionized water soaked for 9 to 11 minutes, then rinsing, repeatedly rinsing multiple times, preferably 10-15 times . After removing the epithelial sheet, the epither piece is placed in acetone solution to remove the photoresist or tear the heat solution.

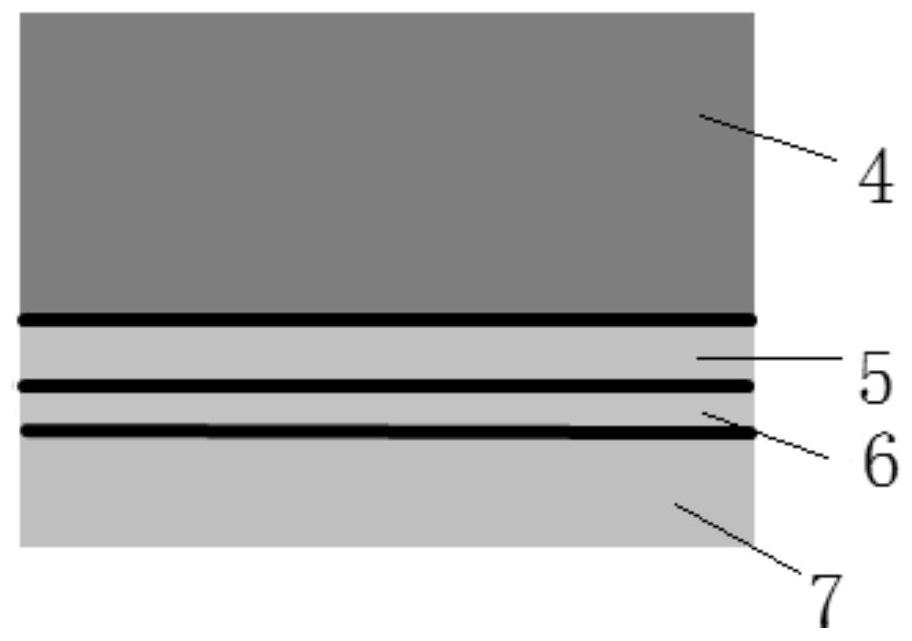

[0032]S2: Place the corrosive epitaxial piece on the vapor deposition jig, put it in a vacuum coating machine, vacuum; the vacuum is reached after the machine sets the value, the baking temperature is set to 90 ~ 110 ° C, bake 8 ~ 12min; After the baking is completed, it is placed in the crucible in the crucible, and the vapo...

Embodiment 2

[0038]S1: Corrosion EtOAc EtOAc EtOAc EtOAc EtOAc EtOAc Solids Soak 55 ~ 65S; after soaking, the epithelial sheet was taken out in the deionized water, and the repeated flushing multiple times, preferably 10-15 times; placed the epithelial sheet in HF: HNO3: H2The O volume ratio of 2: 1: 10 is soaked in the mixed acid solution of 2: 1: 10, so as soon as soaking the epitaxial sheet, the delay is taken out of the deionized water soaked for 9 to 11 minutes, then rinsing, repeatedly rinsing multiple times, preferably 10-15 times The epitaxial sheet is then placed in deionized water for rinsing. After the removal, the epithelial sheet is placed in acetone solution to remove the photoresist or tear the heat solution.

[0039]S2: Put the corrosion of the epitaxial piece on the dedicated carrier is taken out by the robot arm. The vacuum is taken into the first vacuum chamber. When the vacuum reaches the machine set value, the baking temperature is set to 90 ~ 110 ° C, baked 8 to 12 minutes; af...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com