Preparation process of composite membrane for fuel cell

A preparation process and fuel cell technology, applied in fuel cells, circuits, electrical components, etc., can solve the problems of composite membrane penetration and leakage, battery performance degradation, and low proton conductivity, so as to increase hydrophilicity and improve performance , smooth surface effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

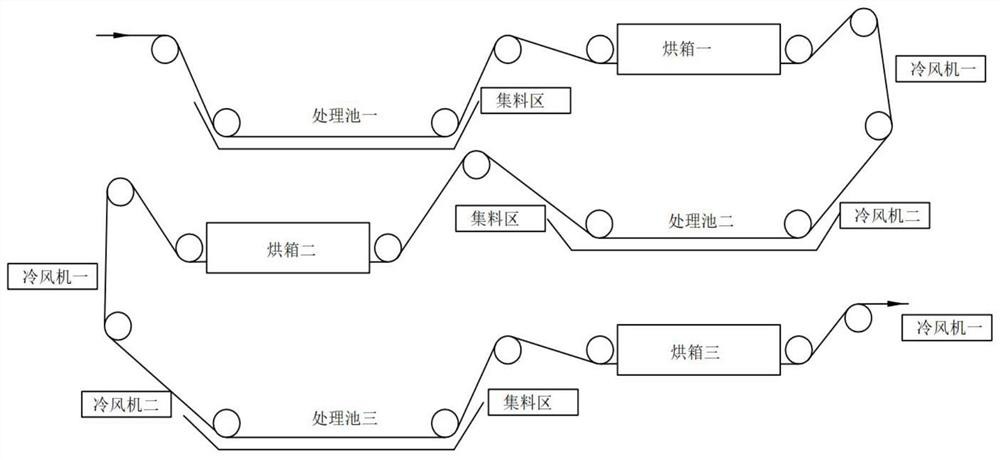

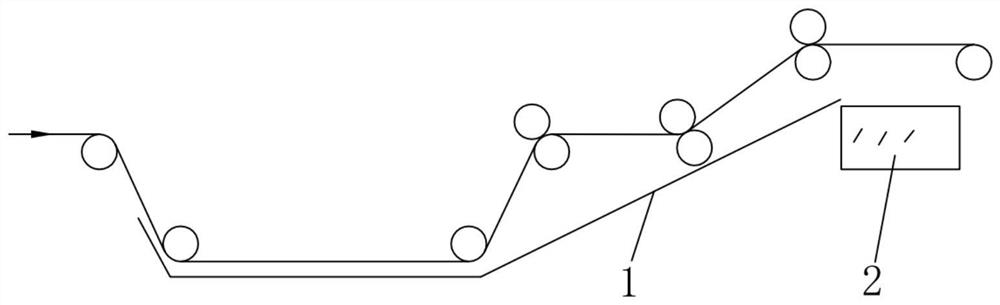

Method used

Image

Examples

Embodiment 1

[0046] a, basement membrane pretreatment: put the expanded polytetrafluoroethylene microporous membrane with a pore size of 1 μm, a porosity of 90%, and a thickness of 1 μm into 3 wt% H 2 o 2 In the solution, cook at 60°C for 20 minutes, and then rinse with a large amount of deionized water. The washing method is to completely immerse the basement membrane in deionized water for 5 seconds and then take it out. Repeat the soaking-taking process 5 times, and there is no H on the surface. 2 o 2 After remaining, soak the base film in isopropanol solvent for 30 minutes, take it out and dry it for 2 hours, then place it in a closed space filled with oxygen, and irradiate it with an ultraviolet lamp with a wavelength of 185nm for 10 minutes, and set it aside.

[0047] b. Solution configuration: take a Nafion solution (perfluorosulfonic acid resin solution) with a concentration of 5wt%, dilute it to a concentration of 0.1wt% with isopropanol as a low-concentration perfluorosulfonic a...

Embodiment 2

[0054] a, basement membrane pretreatment: put the expanded polytetrafluoroethylene microporous membrane with a pore size of 10 μm, a porosity of 80%, and a thickness of 15 μm into 3wt% H 2 o 2 In the solution, cook at 60°C for 20 minutes, and then rinse with a large amount of deionized water. The washing method is to completely immerse the basement membrane in deionized water for 6 seconds and then take it out. Repeat the soaking-taking process 7 times, and there is no H on the surface. 2 o 2 After remaining, soak the base film in isopropanol solvent for 30 minutes, take it out and dry it for 2 hours for later use, then place it in a closed space filled with oxygen, and irradiate it with an ultraviolet lamp with a wavelength of 185nm for 15 minutes for later use.

[0055] b. Solution configuration: take a Nafion solution with a concentration of 5wt%, dilute it to a concentration of 0.5wt% with an isopropanol solvent as a low-concentration perfluorosulfonic acid resin solution...

Embodiment 3

[0062] a, basement membrane pretreatment: put the expanded polytetrafluoroethylene microporous membrane with a pore size of 20 μm, a porosity of 65%, and a thickness of 30 μm into 3wt% H 2 o 2 In the solution, cook at 60°C for 20 minutes, and then rinse with a large amount of deionized water. The washing method is to completely immerse the basement membrane in deionized water for 8 seconds and then take it out. Repeat the soaking-taking process 8 times, and there is no H on the surface. 2 o 2 After remaining, soak the base film in isopropanol solvent for 30 minutes, take it out and dry it for 2 hours for later use, then place it in a closed space filled with oxygen, and irradiate it with an ultraviolet lamp with a wavelength of 185nm for 10 minutes for later use.

[0063] b. Solution configuration: take a Nafion solution with a concentration of 5wt%, dilute it to a concentration of 1wt% with isopropanol solvent as a low-concentration perfluorosulfonic acid resin solution, and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com