Composite material and preparation method thereof

A composite material, biomass carbon technology, applied in chemical instruments and methods, other chemical processes, special compound water treatment, etc., can solve the problem of not finding rGO, and achieve low cost, reliable theoretical and practical support, and the preparation process can be control effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

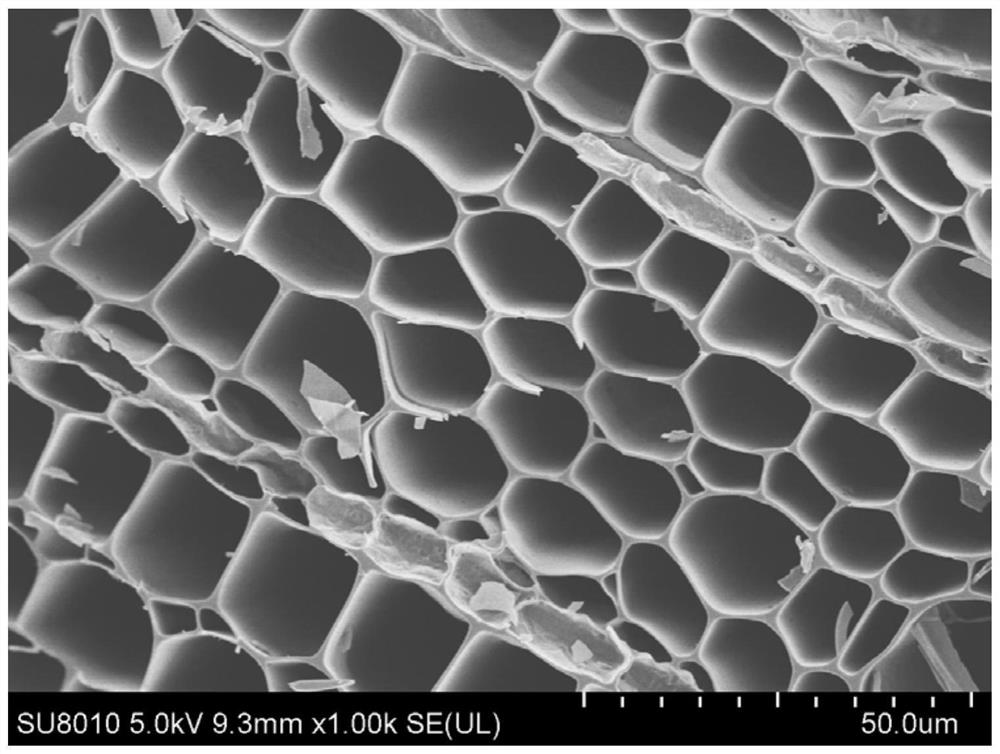

[0042] a) Cut the hemp stalks into small pieces with a length of about 2 mm by using a pulverizer, wash them with ethanol, and dry them in an oven at 70°C for 8 hours, then take out the samples and place them in a tube furnace, and raise the temperature to 400°C under the protection of nitrogen, Calcined at this temperature for 2 hours to obtain biochar.

[0043] b) Soak 80mg of biochar in 40mL of phosphoric acid solution, under magnetic stirring, react at room temperature for 5min, then place it in an oil bath, adjust the temperature to 140°C, and evaporate the water at this temperature to obtain phosphorylated biomass carbon.

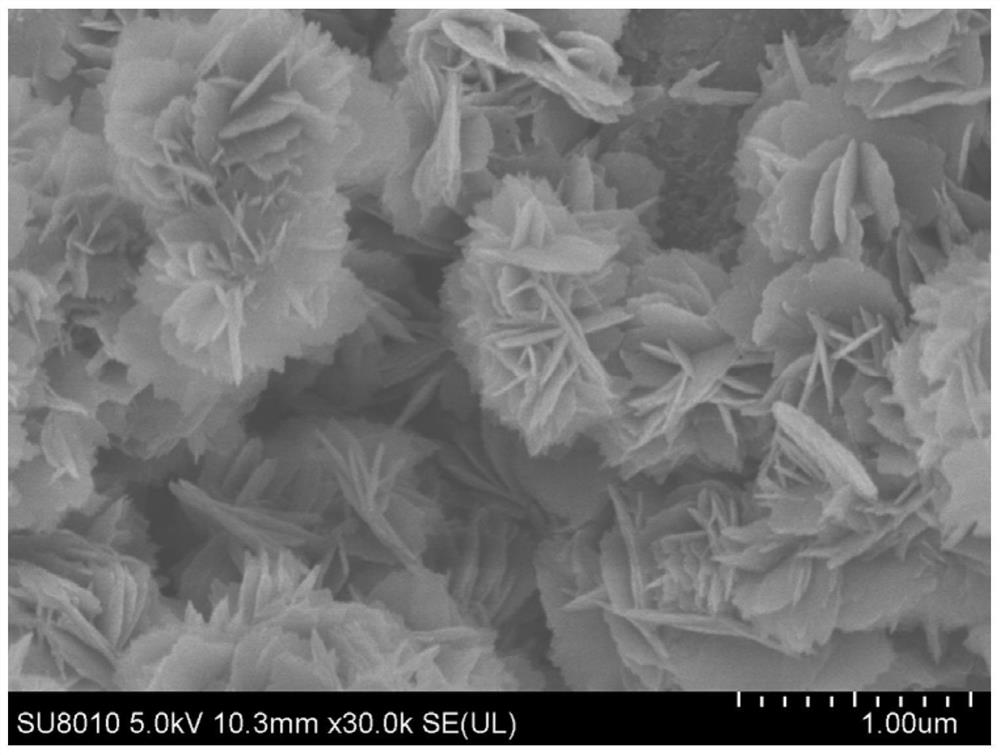

[0044] c) Add 20 mg of reduced graphene oxide (hereinafter referred to as rGO) into 25 mL of deionized water, sonicate for 2 h until it becomes a homogeneous suspension of rGO, then add 3 g of phosphorylated biochar to the suspension, and magnetically stir 2h, a homogeneous suspension was formed.

[0045] d) Then, evaporate the moisture in the above s...

Embodiment 2

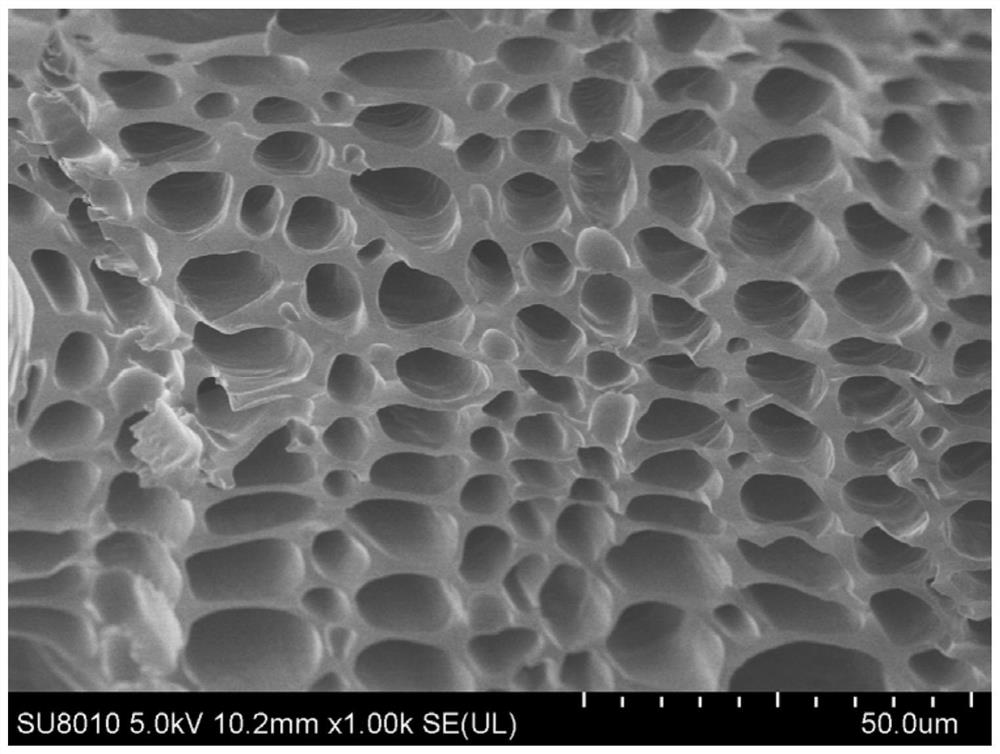

[0049] a) Cut the hemp stalks into small pieces with a length of about 2mm using a pulverizer, wash them with ethanol and dry them in an oven at 70°C for 8 hours, take out the samples and place them in a tube furnace, raise the temperature to 400°C under the protection of nitrogen, and dry in the oven at 70°C. Calcined at high temperature for 2 hours to obtain biochar.

[0050] b) Soak 80mg of biochar in 40mL of phosphoric acid solution, under magnetic stirring, react at room temperature for 5min, then place it in an oil bath, adjust the temperature to 140°C, and evaporate the water at this temperature to obtain phosphorylated biomass carbon.

[0051] c) 20mg rGO was added to 25mL deionized water, and ultrasonically treated for 2h until it became a homogeneous suspension of rGO, then 3g of phosphorylated biochar was added to the suspension, and magnetically stirred for 2h to form a homogeneous suspension.

[0052] d) Evaporate the water in the homogeneous suspension in an oil...

Embodiment 3

[0056] a) Cut the ramie stalks into small pieces with a length of about 2mm by a pulverizer, wash them with ethanol and dry them in an oven at 75°C for 8 hours, take out the samples and place them in a tube furnace, and raise the temperature to 40°C under the protection of nitrogen. calcined for 2 hours to obtain biochar.

[0057] b) Soak 90 mg of biochar in 45 mL of phosphoric acid solution, under magnetic stirring, react at room temperature for 5 minutes, then place it in an oil bath, adjust the temperature to 140 ° C, and evaporate the water at this temperature to obtain phosphorylated biochar Substance charcoal.

[0058] c) 25mg rGO was added to 25mL deionized water, and ultrasonically treated for 2h until it became a homogeneous suspension of rGO, then 3g of phosphorylated biochar was added to the above suspension, and magnetically stirred for 2h to form a suspension.

[0059] d) Then, evaporate the water in the suspension in an oil bath, and place the remaining substanc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com