High-barrier degradable biaxially oriented film and preparation method thereof

A biaxially oriented film, high-barrier technology, applied in chemical instruments and methods, sustainable manufacturing/processing, flat products, etc., can solve problems such as film mechanical properties and barrier properties decline, inability to degrade PET fragments, environmental impact, etc. To achieve the effect of superior performance, easy processing and good performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

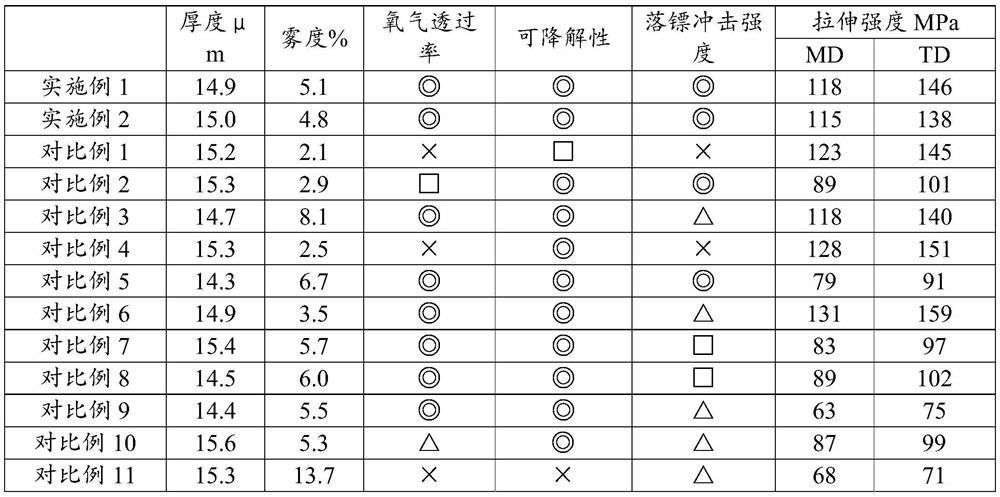

Embodiment 1

[0037] A high-barrier degradable biaxially stretched film in this embodiment is composed of a five-layer film structure, and the five-layer structure is the upper surface layer, the first surface layer, the middle layer, the second surface layer and the lower surface. In parts by mass,

[0038] The upper surface layer includes 50 parts of polylactic acid, 2 parts of compatibilizer, 3 parts of functional masterbatch, 45 parts of polybutylene terephthalic acid / adipate;

[0039] The first surface layer comprises 30 parts of polycaprolactone, 20 parts of cellulose, and 50 parts of starch;

[0040] The middle layer is 30 parts of poly-3-hydroxybutyrate, 2 parts of compatibilizer, 68 parts of carbon dioxide-propylene oxide copolymer;

[0041] The second surface layer comprises 30 parts of polycaprolactone, 20 parts of cellulose, and 50 parts of starch;

[0042] The lower surface layer includes 50 parts of polylactic acid, 2 parts of compatibilizer, 3 parts of functional masterbatch...

Embodiment 2

[0056] The difference between embodiment 2 and embodiment 1 is:

[0057] The high-barrier degradable biaxially stretched film of this embodiment is composed of a five-layer film structure, and the five-layer structure is an upper surface layer, a first surface layer, a middle layer, a second surface layer and a lower surface layer from top to bottom. In parts by mass,

[0058] The upper surface layer includes 40 parts of polylactic acid, 2 parts of compatibilizer, 3 parts of functional masterbatch, 55 parts of polybutylene terephthalic acid / adipate;

[0059] The first surface layer comprises 20 parts of polycaprolactone, 15 parts of cellulose, and 65 parts of starch;

[0060] The middle layer is 20 parts of poly-3-hydroxybutyrate, 2 parts of compatibilizer, 78 parts of carbon dioxide-propylene oxide copolymer;

[0061] The second surface layer comprises 20 parts of polycaprolactone, 15 parts of cellulose, and 65 parts of starch;

[0062] The lower surface layer includes 40 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com