Spraying film waterproof material, two-component spraying film waterproof material and using method thereof

A spray film waterproof, two-component technology, applied in the direction of coating, etc., can solve the problems of the waterproof performance and anti-channeling ability of the waterproof film layer, insufficient adhesion of the waterproof film layer, and increase the difficulty of construction, etc. The ability to resist plant root penetration, improve smoothness and improve construction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

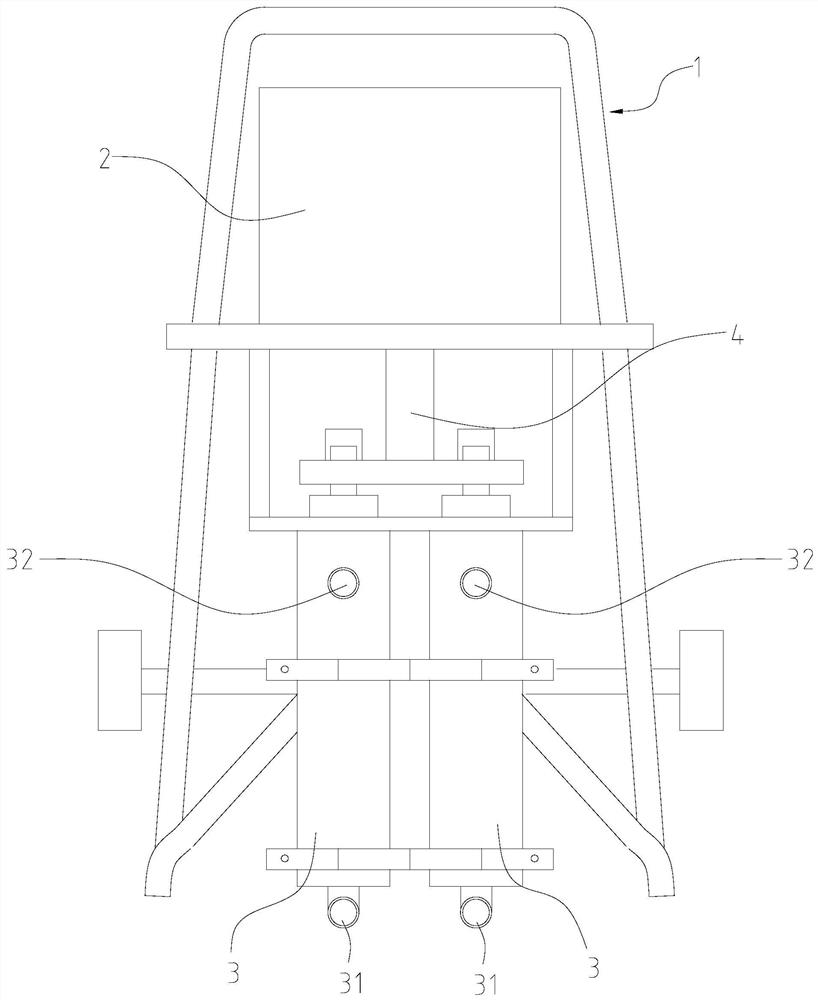

Image

Examples

Embodiment 1

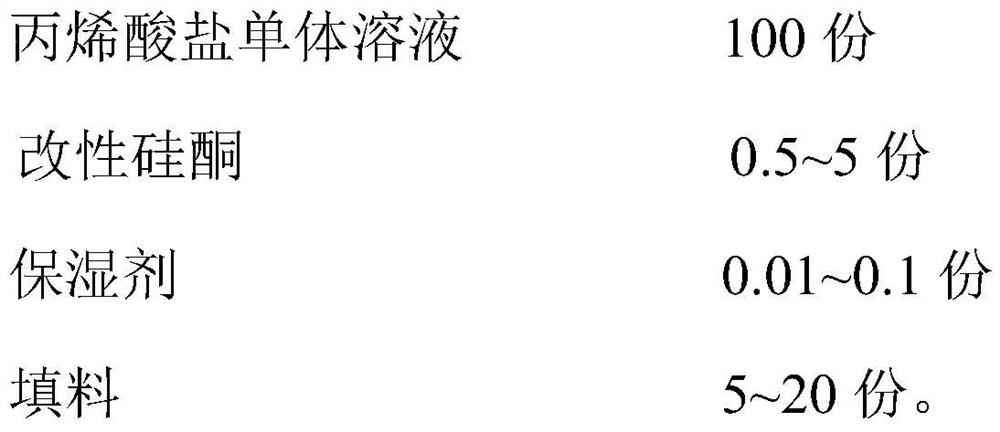

[0049] A two-component spray film waterproof material, including A component and B component, wherein the raw material of component A includes by weight: 100 parts of magnesium acrylate monomer solution; the raw material of component B includes by weight: magnesium acrylate monomer 100 parts of body solution, 0.5 parts of modified silicone, 0.01 part of hydroxyethyl urea, 0.2 parts of white carbon black, 3 parts of talcum powder, and 2 parts of calcium carbonate.

[0050]The preparation method of the waterproof material: take 100 parts of the prepared magnesium acrylate monomer solution as component A; take 100 parts of the prepared magnesium acrylate monomer solution, and then add 0.5 parts of modified silicone, 0.01 part of hydroxyethylurea, 0.3 parts of white carbon black, 3 parts of talcum powder and 2 parts of calcium carbonate are dissolved by high-speed stirring to form component B. The A component is added with the A initiator to form the A mixed solution, and the B co...

Embodiment 2

[0052] A two-component spray film waterproof material, including A component and B component, wherein the raw material of component A includes by weight: 110 parts of magnesium acrylate monomer solution; the raw material of component B includes by weight: magnesium acrylate monomer 100 parts of body solution, 1 part of modified silicone, 0.02 parts of hydroxyethylurea, 0.15 parts of white carbon black, 5 parts of talcum powder, and 3 parts of calcium carbonate.

[0053] The preparation method of the waterproof material: take 110 parts of the prepared magnesium acrylate monomer solution as component A; take 100 parts of the prepared magnesium acrylate monomer solution, and then add 1 part of modified silicone, 0.02 parts of hydroxyethyl urea, 0.15 parts of white carbon black, 5 parts of talcum powder and 3 parts of calcium carbonate are dissolved by high-speed stirring to form component B. The A component is added with the A initiator to form the A mixed solution, and the B com...

Embodiment 3

[0055] A two-component spray film waterproof material, including A component and B component, wherein the raw material of component A includes by weight: 115 parts of magnesium acrylate monomer solution; the raw material of component B includes by weight: magnesium acrylate monomer 100 parts of body solution, 2 parts of modified silicone, 0.05 parts of hydroxyethyl urea, 0.1 part of white carbon black, 5 parts of talcum powder, and 5 parts of calcium carbonate.

[0056] The preparation method of the waterproof material: take 110 parts of the prepared magnesium acrylate monomer solution as component A; take 100 parts of the prepared magnesium acrylate monomer solution, and then add 2 parts of modified silicone, 0.05 parts of hydroxyethyl urea, 0.1 part of white carbon black, 5 parts of talcum powder and 5 parts of calcium carbonate are dissolved by high-speed stirring to form component B. The A component is added with the A initiator to form the A mixed solution, and the B comp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com