Night self-luminous insulating wire paint as well as preparation and coating methods thereof

An insulated wire, self-luminous technology, used in luminescent coatings, insulators, coatings, etc., can solve the problems of lack of self-luminous materials, low insulation safety performance, poor self-luminous durability, etc., to achieve good corrosion resistance and stable insulation. Protective effect, enhance self-luminous effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

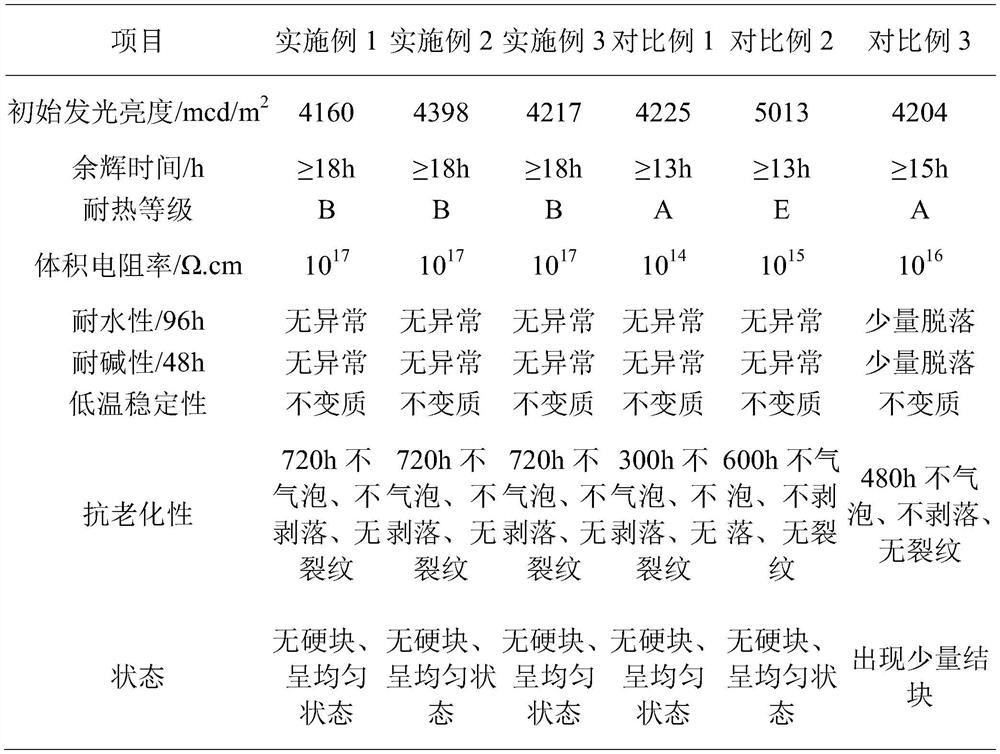

Examples

Embodiment 1

[0023] Embodiment 1-a kind of self-illuminating insulating wire paint at night, comprises 52 parts of luminescent base materials and 15 parts of composite fiber fabrics according to the ratio in parts by weight;

[0024] The luminescent base material is composed of the following raw material components according to the ratio of parts by weight: 20 parts of epoxy resin, 8 parts of acrylic resin, 5 parts of chlorinated polypropylene resin, 4 parts of hollow glass microspheres, 6 parts of vinyl silicone oil, Composed of 10 parts of aluminate phosphor, 9 parts of filler, 3 parts of dispersant and 1 part of compatibilizer;

[0025] The composite transparent fiber fabric is composed of the following raw material components according to the ratio of parts by weight: 3 parts of modified bamboo fiber, 7 parts of dihydroxypolydimethylsiloxane, 2 parts of transparent polyamide resin and 2 parts of polyether modified The composition of silicone oil;

[0026] The solubilizer is mixed with...

Embodiment 2

[0029] Embodiment 2-a kind of self-illuminating insulating wire paint at night, according to the ratio of parts by weight, including 64 parts of luminous base materials and 23 parts of composite fiber fabrics;

[0030] The luminescent base material is composed of the following raw material components according to the ratio of parts by weight: 22 parts of epoxy resin, 14 parts of acrylic resin, 10 parts of chlorinated polypropylene resin, 8 parts of hollow glass microspheres, 8 parts of vinyl silicone oil, Composed of 13 parts of aluminate phosphor, 11 parts of filler, 5 parts of dispersant and 2 parts of compatibilizer;

[0031] The composite transparent fiber fabric is composed of the following raw material components according to the ratio of parts by weight: 6 parts of modified bamboo fiber, 10 parts of dihydroxypolydimethylsiloxane, 4 parts of transparent polyamide resin and 3 parts of polyether modified Composition of silicone oil.

[0032] The solubilizer is mixed with ...

Embodiment 3

[0035] Embodiment 3-a kind of self-illuminating insulating wire paint at night, according to the ratio of parts by weight, including 60 parts of luminous base materials and 20 parts of composite fiber fabrics;

[0036] The luminescent base material is composed of the following raw material components according to the ratio of parts by weight: 21 parts of epoxy resin, 11 parts of acrylic resin, 7 parts of chlorinated polypropylene resin, 6 parts of hollow glass microspheres, 7 parts of vinyl silicone oil, Composed of 12 parts of aluminate phosphor, 10 parts of filler, 4 parts of dispersant and 1.5 parts of compatibilizer;

[0037] The composite transparent fiber fabric is composed of the following raw material components according to the ratio in parts by weight: 4 parts of modified bamboo fiber, 8 parts of dihydroxypolydimethylsiloxane, 3 parts of transparent polyamide resin and 2.5 parts of polyether modified Composition of silicone oil.

[0038] The solubilizer is mixed wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com