Ion beam sputtering film high-temperature strain gauge and preparation method thereof

An ion beam sputtering, high temperature strain gauge technology, applied in the field of sensors, can solve the problems affecting the zero drift of the strain gauge creep, sensitivity coefficient, reducing the reliability of the strain gauge, and the denaturation failure of the adhesive. Density and reliability improvement, the effect of improving the bonding force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

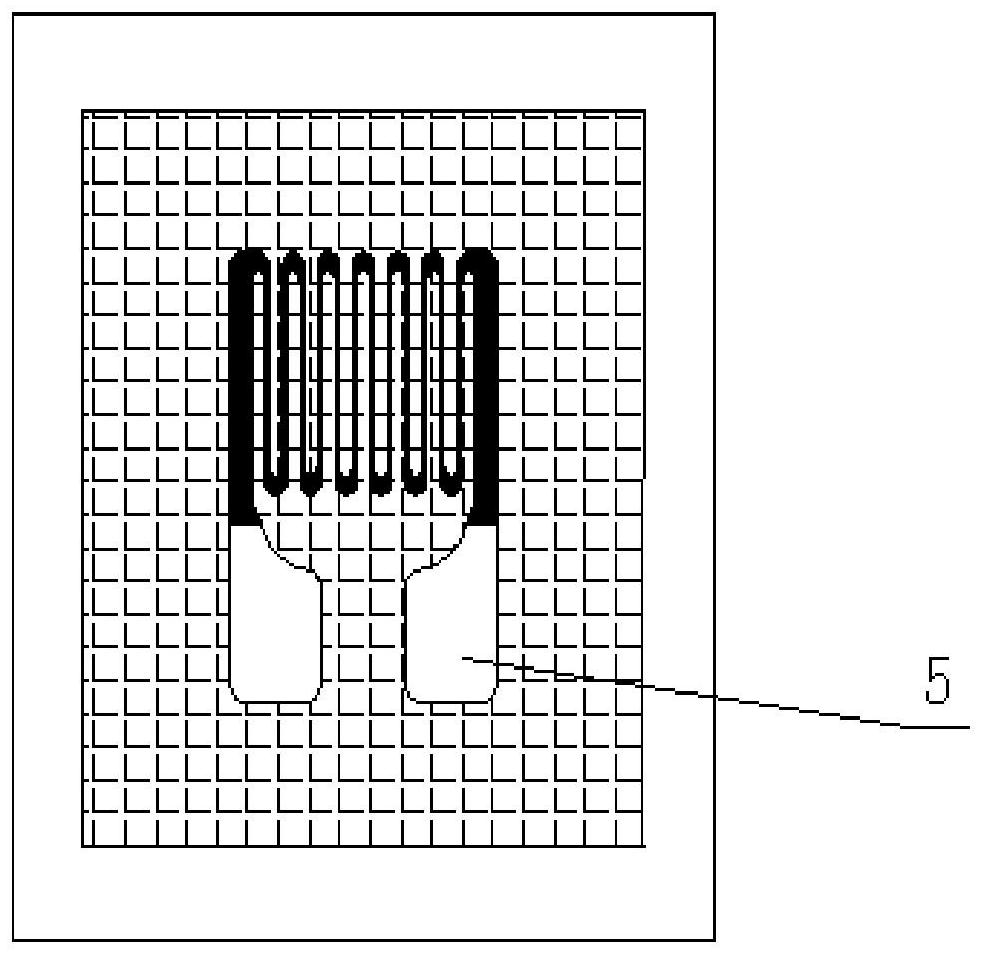

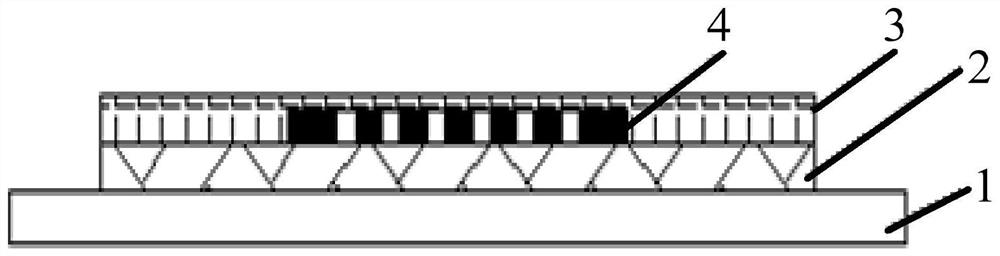

[0044] refer to figure 1 and figure 2 , the embodiment of the present invention provides an ion beam sputtering thin film high temperature strain gauge, which can be used for measuring blade strain parameters of aeroengines; the ion beam sputtering thin film high temperature strain gauge includes a nickel-based alloy substrate 1, an insulating film layer 2, Nickel-chromium wire grid film layer 3, protective film layer 4 and electrode film 5; nickel-based alloy substrate 1, insulating film layer 2, and nickel-chromium wire grid film layer 3 are stacked sequentially from bottom to top; electrode film 5 and protective film Layer 4 is arranged on the same layer, and both are arranged on the top of nickel-chromium wire grid thin film layer 3;

[0045] The nickel-based alloy substrate 1 is used as the basis of the entire strain gauge; the thickness of the nickel-based alloy substrate 1 can be 10 μm; the insulating film layer 2 can be SiO 2 / Si 3 N 4 Composite insulating film la...

Embodiment 2

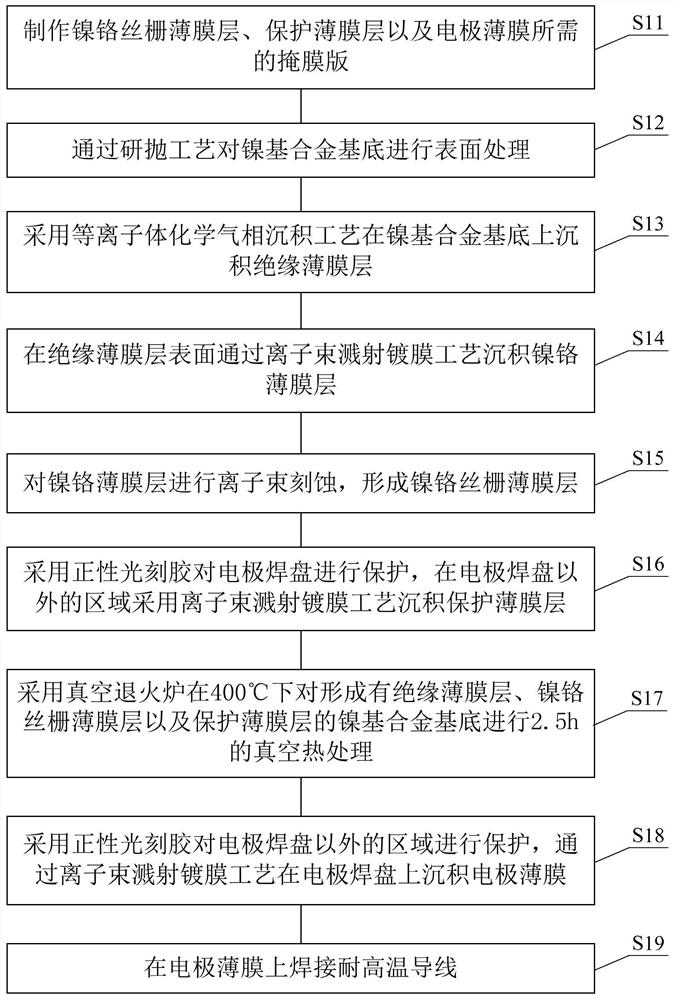

[0052] The embodiment of the present invention also provides a method for preparing the ion beam sputtered thin film high temperature strain gauge, refer to image 3 , including the following specific steps:

[0053] Step S11, making the mask plate required for the nickel-chromium wire grid film layer 3, the protective film layer 4 and the electrode film 5; before preparation, it is necessary to design and manufacture the nickel-chromium wire grid film layer 3, the protective film layer 4 and The mask pattern required for the electrode film 5, and prepare the corresponding mask plate according to the mask pattern processing;

[0054] Step S12, performing surface treatment on the nickel-based alloy substrate 1 through a polishing process, so that the surface roughness of the nickel-based alloy substrate 1 is less than 5nm; in order to meet the requirements of the deposition process, it is necessary to perform surface pretreatment on the nickel-based alloy substrate 1 before dep...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com