Preparation formula and preparation device of beef cattle feed

A feed, beef cattle technology, applied in feed, animal feed, animal feed and other directions, can solve the problems of incomplete nutrition, inability to make full use of straw resources, low vitality, etc., to improve digestibility and palatability, increase feed conversion efficiency, The effect of increasing the daily quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] refer to Figure 1-4 , a preparation formula for beef cattle feed, comprising the following steps:

[0030] S1. Weighing raw materials: corn stalk compressed block, peptone, sucrose, NaCl, water and lignocellulosic bacteria solution;

[0031] S2, the prepared lignocellulose decomposing bacteria solution 8.0 × 10 9 CFU / ml is diluted 30 times with 2% peptone aqueous solution, and then the diluted lignocellulosic decomposing bacteria solution and the compressed corn stalks are uniformly sprayed on the compressed corn stalks according to the mass ratio of 5:2;

[0032] S3. Stirring the sprayed compressed corn stalks for 5-10 minutes into the fermentation tank, controlling the fermentation temperature to be kept at 58-62°C, stirring for 5-10 minutes every day, and discharging after 5 days of fermentation;

[0033] S4. The peptone, sucrose, NaCl and water in S1 are prepared in a mass ratio of 4:2:1:500 to prepare 30L of fermented bacteria culture solution, boiled for 8-12min,...

Embodiment 2

[0039] Embodiment 2: the difference based on Embodiment 1 is;

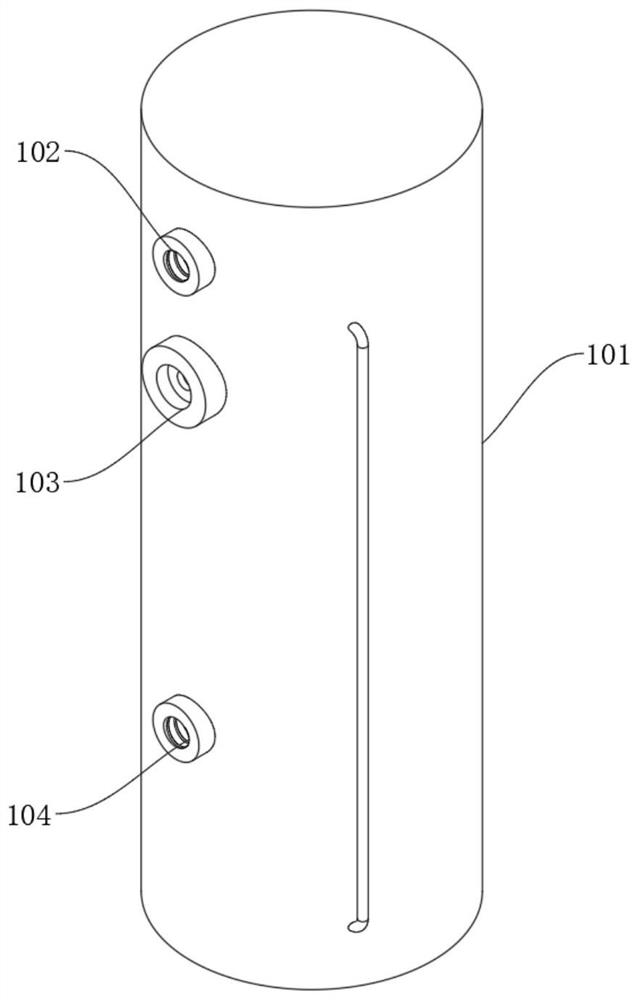

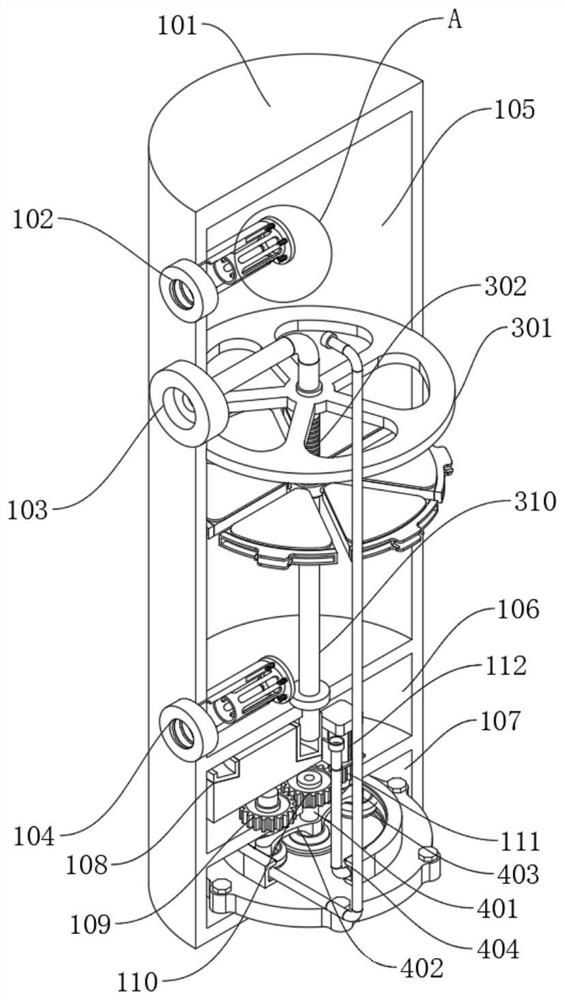

[0040] A bacterial liquid culture tank for the preparation formula of beef cattle feed, comprising a bacterial liquid fermentation shell 101, a feed pipeline 102, an inoculation pipeline 103 and a discharge pipeline 104, and the bacterial liquid fermentation shell 101 is sequentially provided with a culture bin 105, The drive bin 106 and the flow bin 107, the outer surface of the cultivation bin 105 are provided with a feed pipe 102, an inoculation pipe 103, and a discharge pipe 104 in sequence from top to bottom, and the feed pipe 102 and the discharge pipe 104 are arranged on the inner side. There is an anti-suckback sealing mechanism. The inoculation pipeline 103 extends to the inside of the culture chamber 105 and is fixedly connected with the microorganism inoculation and cultivation mechanism. The axis is fixedly connected to the axis of the linkage gear 109 through the rotating shaft, the lower end of the u...

Embodiment 3

[0044] Embodiment 3: based on Embodiment 1 and 2, but different again is;

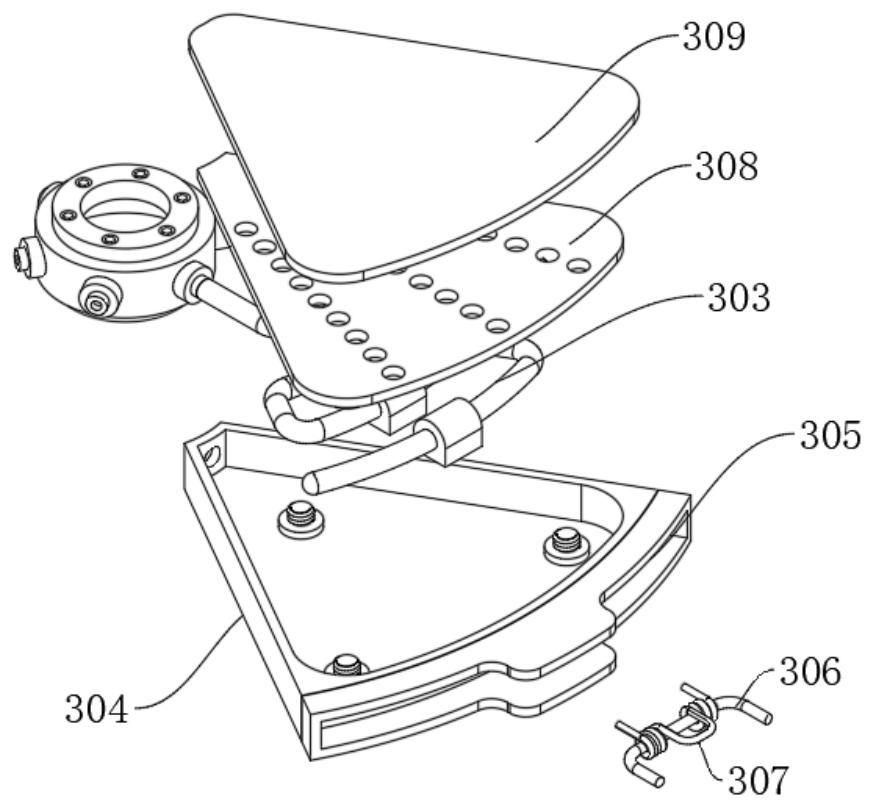

[0045] The upper side of the inoculation pipeline 103 is fixedly installed with a fixed ring 301, and the interior of the inoculation pipeline 103 is located below the fixed ring 301 and is equipped with six sets of microbial feeding devices in a ring shape. The microbial feeding devices include: bellows 302, circular distribution pipeline 303, Fluctuating housing 304, connecting housing 305, connecting shaft 306, torsion spring 307, microbial overflow orifice 308, microbial attachment plate 309 and undulating column 310, the lower end of inoculation pipeline 103 is fixedly connected with the upper end of bellows 302, and the lower end of bellows 302 passes through the pipeline and One end of the round-shaped distribution pipe 303 is fixedly connected, and the round-shaped distribution pipe 303 is fixedly installed inside the fluctuating shell 304. The upper side of the fluctuating shell 304 is fixedly ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com