Combined power generator of high temperature heat source-oxygen concentration cell pile

A power generation device and high-temperature heat source technology, which is applied in the application of power generation and nuclear power generation, can solve the problems of complex auxiliary control system, adverse environmental impact, and unfavorable environment, and achieve high energy conversion efficiency, fewer high-speed rotating parts, and low temperature high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0056] Embodiment 1 is a power generation device of a high temperature gas-cooled stack-oxygen concentration difference battery stack direct cycle system using an oxygen separation system. Its structure is as Figure 4 shown. In the figure, 41-high temperature gas-cooled reactor; 42-fan; 43-oxygen separation system; 44-oxygenator; 45-oxygen-helium mixed gas transportation pipeline; 46-oxygen chamber; 47-oxygen concentration battery; 48-card Groove; 49-thermocouple; 410-oxygen chamber wall; 411-temperature control system; 412-insulation layer; 413-shell; 414-preheater. As can be seen from the figure, the high-temperature helium gas coming out from the high-temperature gas-cooled reactor core directly passes through the inner cavity of the oxygen concentration difference battery 47 of the oxygen concentration difference battery stack, and the oxygen concentration difference battery in the oxygen concentration difference battery stack is heated to make the Its temperature reach...

Embodiment 2

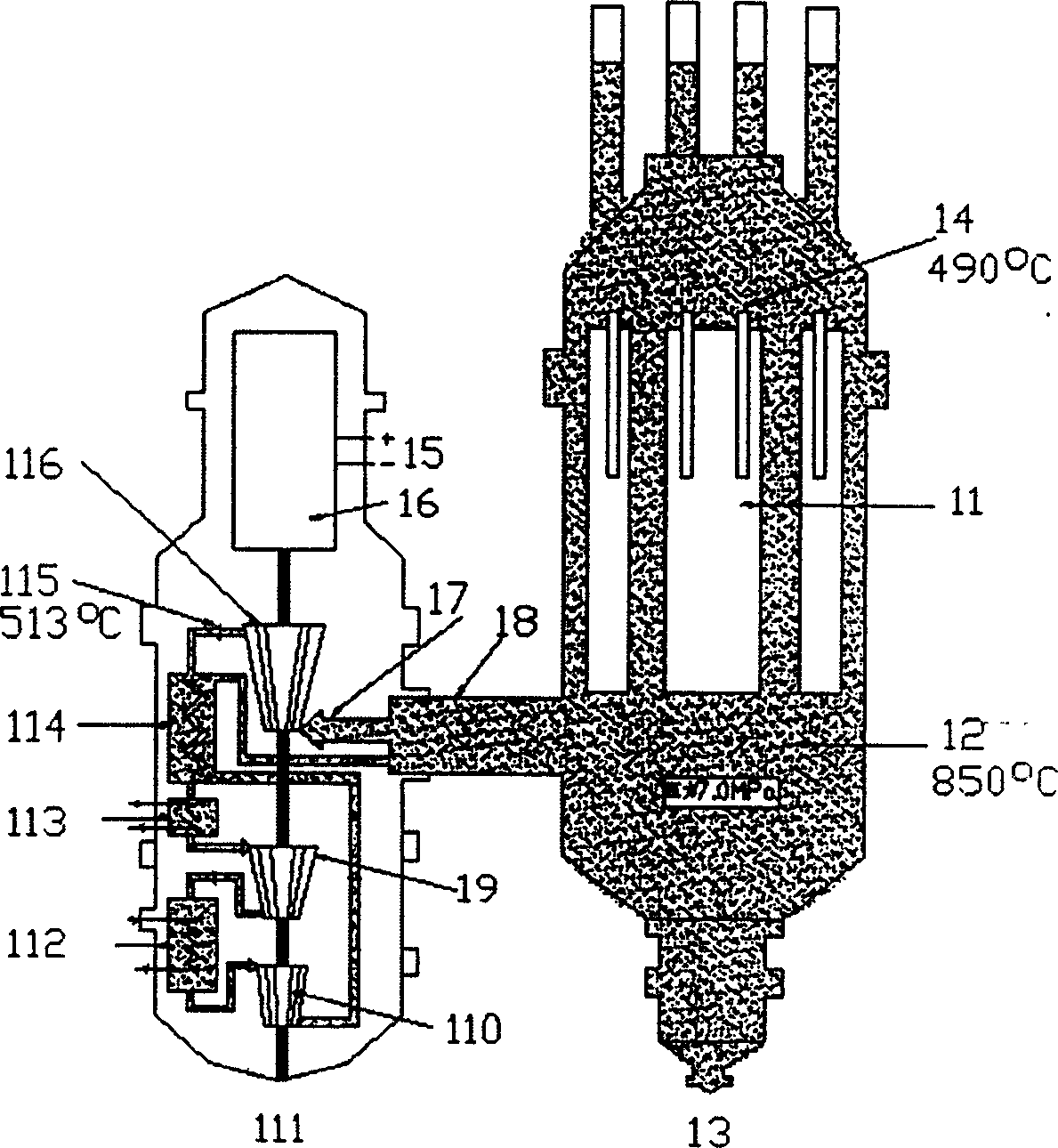

[0057] Embodiment 2 is a combined power generation device of a high-temperature gas-cooled stack-oxygen concentration stack direct cycle system using a vacuum pump system. Its structure is as Figure 5 shown. In the figure, 51-high temperature gas-cooled reactor; 52-fan; 53-oxygen concentration difference battery; 54-card slot; 55-steel shell; 56-thermocouple; 57-oxygen chamber wall; 58-temperature control system; 510-vacuum pump; 511-oxygen transport pipeline; 512-oxygen chamber; 513-insulation layer; 514-heat exchange components; 515-oxygen chamber.

[0058] It can be seen from the figure that the high-temperature helium gas coming out of the high-temperature gas-cooled reactor core directly passes through the inner cavity of the heat exchange component 514 in the oxygen chamber, and heats the oxygen concentration cells in the oxygen concentration cell stack to make the temperature reach 500- 1000°C. Part of the oxygen in the oxygen chambers 512 and 515 enters the inner c...

Embodiment 3

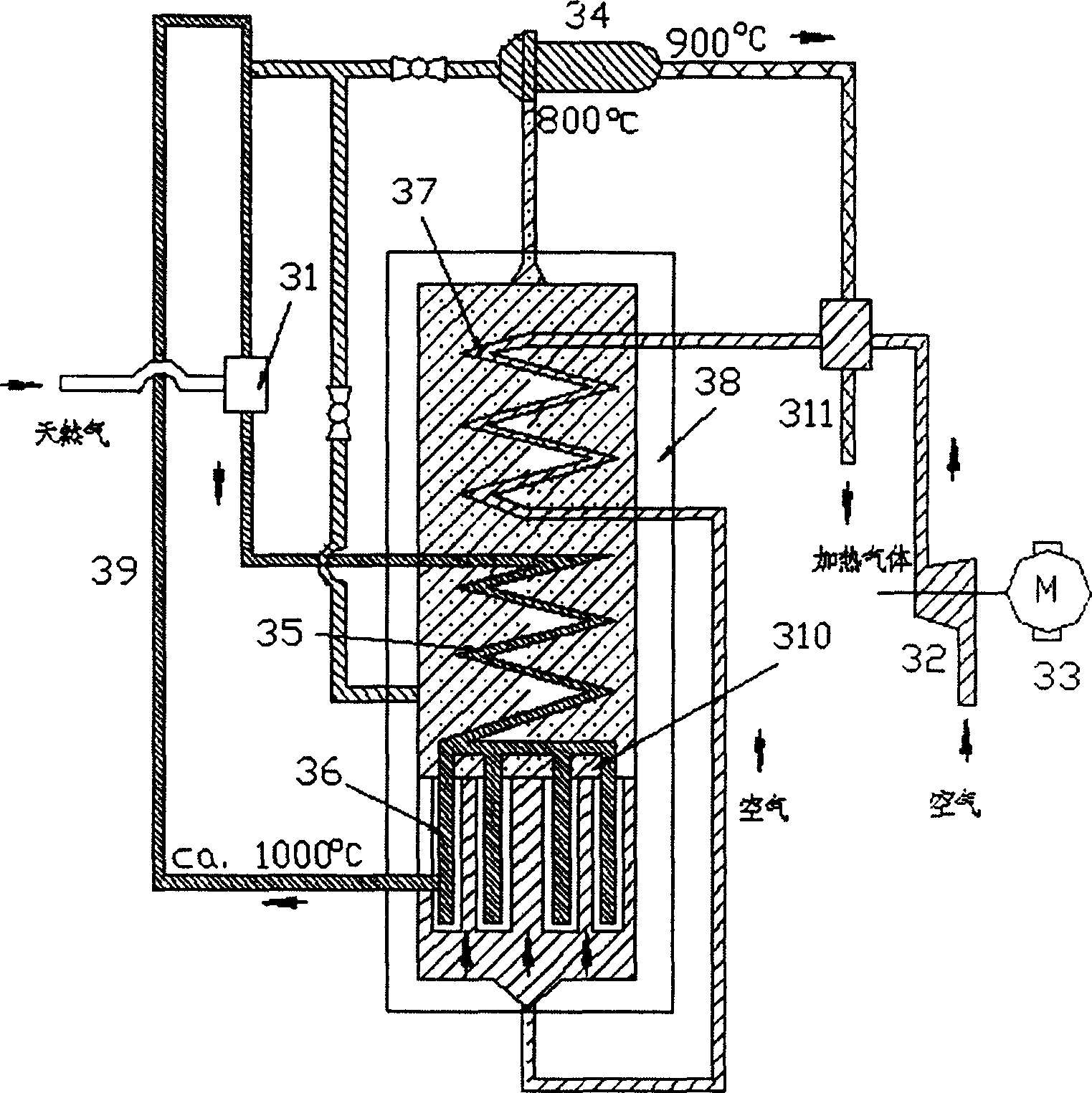

[0059] Embodiment 3 is a high temperature gas-cooled stack-oxygen concentration difference battery stack indirect circulation system combined power generation device using an oxygen separation system. Its structure is as Figure 6 shown. In the figure 61-high temperature gas-cooled reactor; 62-fan; 63-heat exchanger; 64-oxygen concentration battery; 65-card slot; 66-thermocouple; 67-oxygen chamber wall; 68-compressor; 69-oxygen Separation system; 610-Oxygen supplement; 611-Oxygen chamber; 612-Temperature control system; 613-Insulation layer; 614-Shell; 615-Preheater.

[0060] The system has two loops. The primary loop consists of a high temperature gas-cooled stack, a fan and a heat exchanger. The oxygen concentration difference battery stack is composed of many oxygen concentration difference batteries connected in series and parallel. The oxygen concentration cell stack is located in the oxygen chamber. The oxygen chamber is composed of the outer wall of the oxygen conc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| voidage | aaaaa | aaaaa |

| voidage | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com