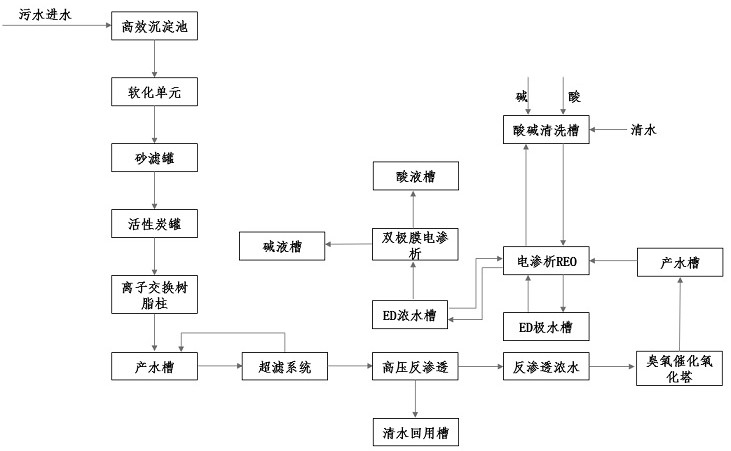

Zero-discharge treatment process for organic wastewater

A treatment process and organic wastewater technology, applied in the field of zero discharge of water treatment, can solve problems such as inability to use directly, waste of water resources, and great environmental hazards, and achieve the effects of reducing membrane pollution, interference, and inorganic pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] The organic wastewater of a steel factory adopts the treatment system and treatment method of the present invention after the biological aeration tank. The organic wastewater is pumped from the biological aeration tank to the high-efficiency sedimentation tank. The high-efficiency sedimentation tank is an advection sedimentation tank, and the sedimentation tank Including, water inlet area, sedimentation area, water outlet area and sludge area. The number of sedimentation tanks is 3, in order to switch work when a failure occurs. The aspect ratio of the sedimentation tank is 5. The effective water depth is 1m, and the slope of the sludge bucket is less than 42°. The super-high part around the sedimentation tank is 0.4 m to control abnormal water level and cause water overflow. The mud discharge pipe is generally made of stainless steel with a diameter of 400 mm. The water treated by the high-efficiency sedimentation tank enters the softening unit and should overflow b...

Embodiment 2

[0052] The organic wastewater of a steel factory adopts the treatment system and treatment method of the present invention after the biological aeration tank. The organic wastewater is pumped from the biological aeration tank to the high-efficiency sedimentation tank. The high-efficiency sedimentation tank is an advection sedimentation tank, and the sedimentation tank Including, water inlet area, sedimentation area, water outlet area and sludge area. The number of sedimentation tanks is 4, in order to switch work when a failure occurs. The aspect ratio of the sedimentation tank is 6. The effective water depth is 1.2m, and the slope of the sludge bucket is less than 45°. The super-high part around the sedimentation tank is 0.5 m to control abnormal water level and cause water overflow. The mud discharge pipe is generally made of stainless steel with a diameter of 500 mm. The water treated by the high-efficiency sedimentation tank enters the softening unit and should overflow...

Embodiment 3

[0062] The organic wastewater of a steel factory adopts the treatment system and treatment method of the present invention after the biological aeration tank. The organic wastewater is pumped from the biological aeration tank to the high-efficiency sedimentation tank. The high-efficiency sedimentation tank is an advection sedimentation tank, and the sedimentation tank Including, water inlet area, sedimentation area, water outlet area and sludge area. The number of sedimentation tanks is 5, in order to switch work when a failure occurs. The aspect ratio of the sedimentation tank is 7. The effective water depth is 1.5m, and the slope of the sludge bucket is less than 50°. The super-high part around the sedimentation tank is 0.6 m to control abnormal water level and cause water overflow. The mud discharge pipe is generally made of stainless steel with a diameter of 600 mm. The water treated by the high-efficiency sedimentation tank enters the softening unit and should overflow...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com