Waterproof moisture-permeable polyurethane film with environmental response function and preparation method thereof

A polyurethane film, waterproof and moisture-permeable technology, applied in the field of new materials, can solve the problems of no temperature sensing function, poor wearing comfort, and low response accuracy, and achieve high environmental temperature response accuracy, improved moisture permeability, and reduced process steps. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] This embodiment provides a waterproof and moisture-permeable polyurethane film with environmental response function, which is made of the following raw materials in weight percentage:

[0024]

[0025] The preparation method of the waterproof and moisture-permeable polyurethane film with environmental response function comprises the following steps:

[0026] (1) 30% by weight of diphenylmethane diisocyanate and 8% by weight of 1,4-butanediol were mixed and reacted at 85° C. for 1 hour;

[0027] (2) Adding 10% polyhydroxypropyl methyl methacrylate and 60% polyethylene glycol by weight, keeping the temperature at 85° C., and reacting for 3 hours;

[0028] (3) Blow molding / casting the molten raw material into a film through a blow molding machine / casting machine.

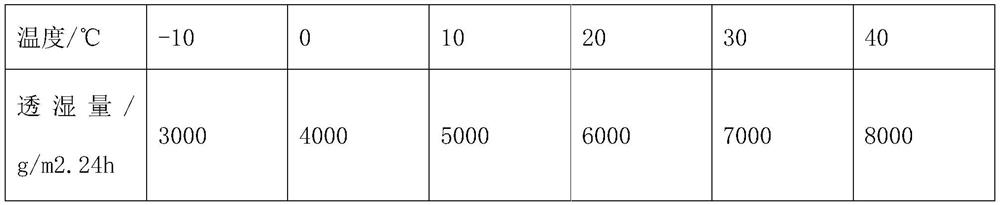

[0029] The moisture permeability test data of the above-mentioned waterproof and moisture-permeable polyurethane film with environmental response function at different temperatures are as follows:

[0030] ...

Embodiment 2

[0034] This embodiment provides a waterproof and moisture-permeable polyurethane film with environmental response function, which is made of the following raw materials in weight percentage:

[0035]

[0036] The preparation method of the waterproof and moisture-permeable polyurethane film with environmental response function comprises the following steps:

[0037] (1) 15% by weight of diphenylmethane diisocyanate and 10% by weight of 1,3-butanediol were mixed and reacted at 85° C. for 1 hour;

[0038] (2) adding 20% polyhydroxypropyl methyl methacrylate and 45% polyethylene glycol by weight, keeping the temperature at 85° C., and reacting for 3 hours;

[0039] (3) Blow molding / casting the molten raw material into a film through a blow molding machine / casting machine.

[0040] The moisture permeability test data of the above-mentioned waterproof and moisture-permeable polyurethane film with environmental response function at different temperatures are as follows:

[004...

Embodiment 3

[0044] This embodiment provides a waterproof and moisture-permeable polyurethane film with environmental response function, which is made of the following raw materials in weight percentage:

[0045]

[0046] The preparation method of the waterproof and moisture-permeable polyurethane film with environmental response function comprises the following steps:

[0047] (1) 15% by weight of diphenylmethane diisocyanate and 10% by weight of 2-methyl-1,3-propanediol were mixed and reacted at 85° C. for 1 hour;

[0048] (2) adding 15% polyhydroxypropyl methyl methacrylate and 50% polyethylene glycol by weight, keeping the temperature at 85° C., and reacting for 3 hours;

[0049] (3) Blow molding / casting the molten raw material into a film through a blow molding machine / casting machine.

[0050] The moisture permeability test data of the above-mentioned waterproof and moisture-permeable polyurethane film with environmental response function at different temperatures are as follows:...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com