Treatment device for industrial waste gas

A treatment device and technology for industrial waste gas, applied in climate change adaptation, climate sustainability, damage protection, etc., can solve problems such as unmitigated urban air pollution, poor urban air quality, and pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

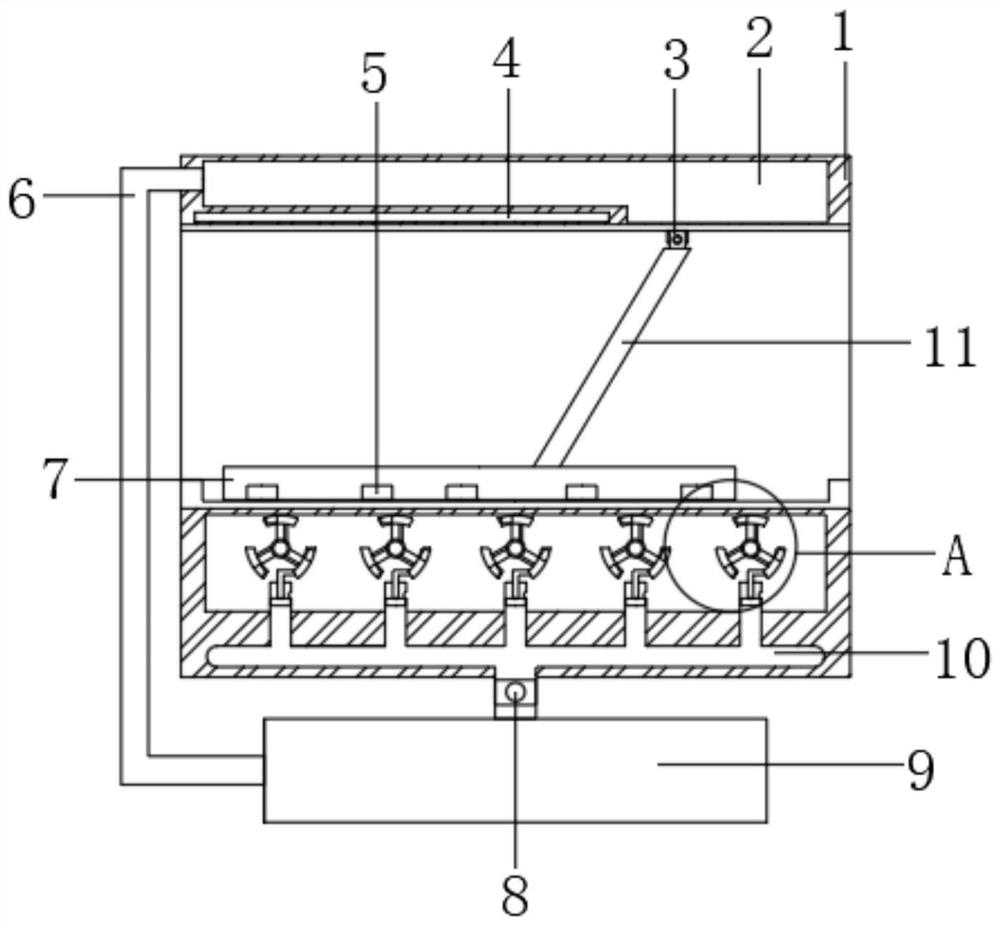

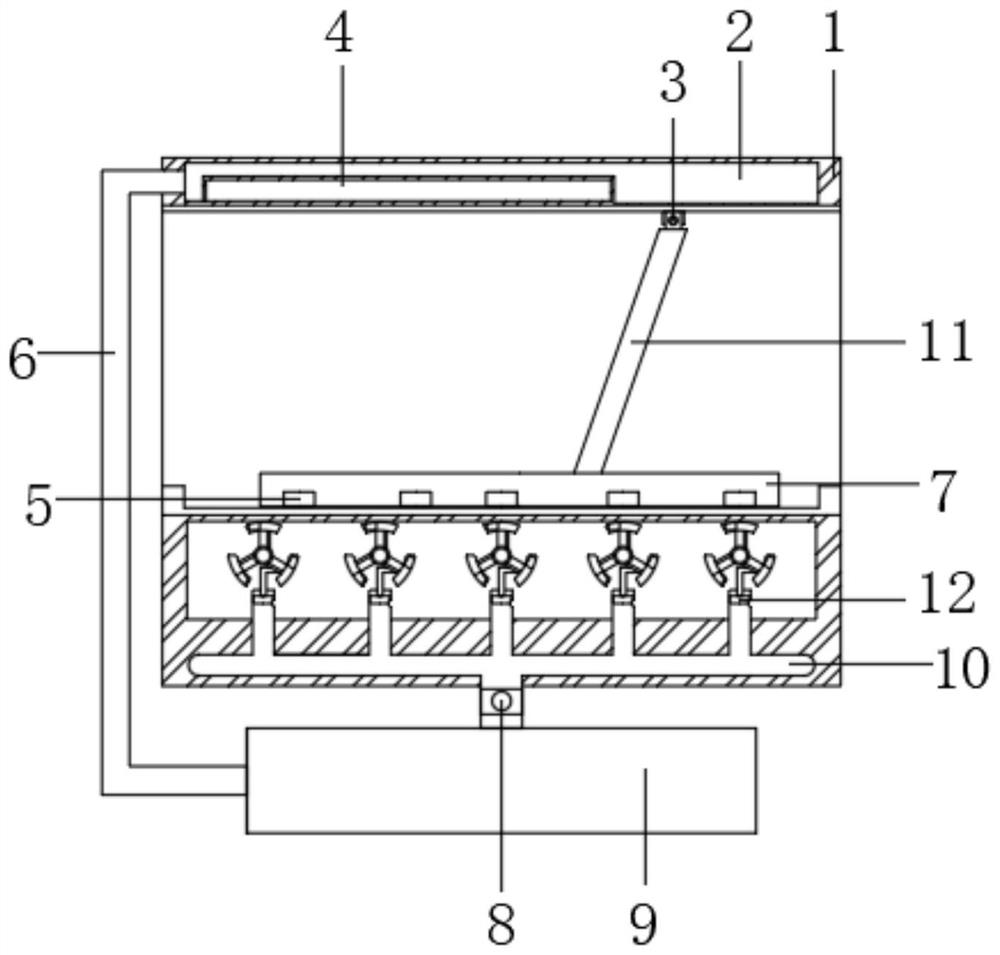

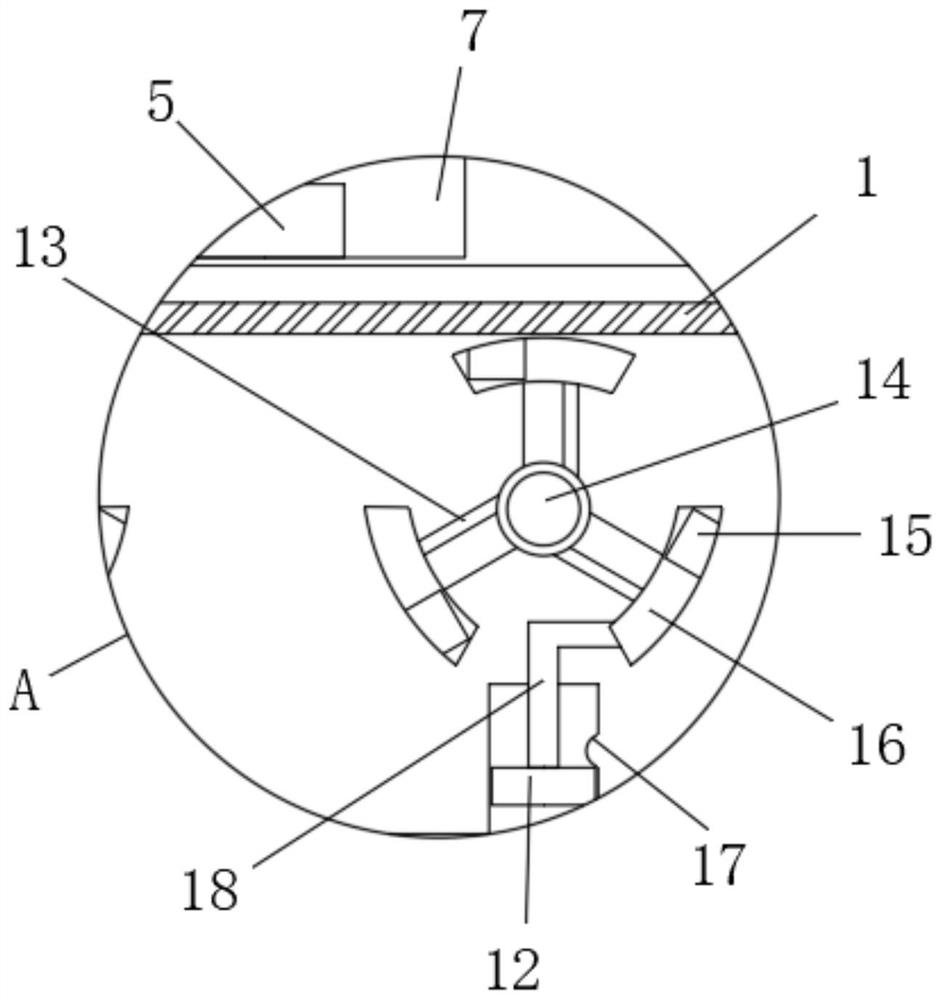

[0021] refer to Figure 1-3 , a treatment device for industrial waste gas, comprising an annular hollow casing 1 and a cooling box 9 arranged on one side of the casing 1, the casing 1 is provided with an elastic cavity 4 for storing low boiling point evaporative liquid, The housing 1 is provided with an annular cooling chamber 2, the cooling chamber 2 is filled with cooling liquid, the cooling chamber 2 is fixedly connected with the first communication pipe 6 and the second communication pipe 10 for connecting the cooling box 9, and the second communication pipe 10 is connected to the cooling chamber 2. The pipe 10 and the cooling chamber 2 are connected to each othe...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap